Concrete contact - primer for surface preparation

Have you encountered such a problem as peeling paint, crumbling plaster or wallpaper peeling off the walls almost immediately after the repair is completed?

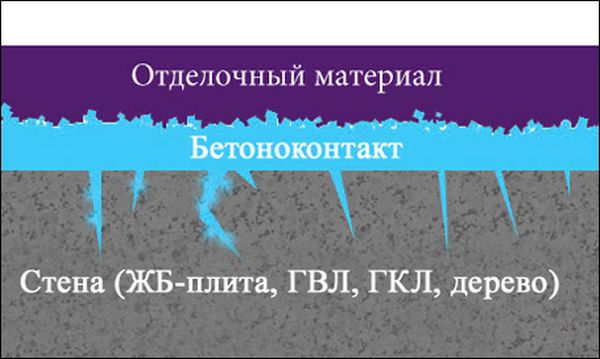

If so, then surely the reason is that the builders or you yourself did not prepare the base for the finish, did not provide adhesion (adhesion) of the materials. This property is easily attached to them by Knauf Primer Concrete Contact or other similar means intended for impregnation of surfaces before finishing.

The content of the article

Application

In order for different materials to adhere well to each other during leveling and surface finishing, they must have good adhesion properties. They are provided by special construction impregnations - primers.

Among them there are both universal compounds and special ones designed to improve the properties of certain materials - wood, brick, metal.

Application area

Among the many others, the Concrete Contact primer is universal - its composition allows you to use the tool for working on concrete, brick, drywall, surfaces painted with oil paint or finished ceramic tiles, as well as many other materials.

In a word, when doing repairs in your apartment with your own hands, you can use Concrete Contact almost anywhere:

- For processing floor slabs before creating a screed or a bulk floor device;

- For impregnation of walls and partitions before plaster or putty;

- To strengthen and reduce the porosity of drywall before painting, sticker wallpaper or tiling;

- To prepare ceilings for whitewashing, etc.

According to the requirements of GOST, Primer Concrete Contact should be used for the preparation of non-absorbent substrates, which include surfaces painted with varnish, enamel or oil paint, coated with glazed tiles. If you want to change the finish, it is not necessary to dismantle the old coating - just cover it with a primer layer, which will give it a roughness and stickiness, providing good adhesion to other finishing materials.

Features of use

This tool is intended for internal use and can only be used in the temperature range from +5 to +35 degrees under normal humidity. The instruction does not allow its storage and use at low temperatures, since in this case it is impossible to guarantee the quality of the coating.

But a properly treated surface can be operated at temperatures from -40 to +50 degrees.

Note. Some manufacturers include special additives in the primer to ensure frost resistance. Thanks to them, the composition withstands up to three cycles of freezing and thawing at a temperature of minus 15-20 degrees for a duration of no more than two hours. This makes it possible to transport the material to the object in winter without losing its properties.

In addition to observing the temperature regime, there are other requirements that are mandatory for execution when carrying out priming work, regardless of whether Concrete contact or another type of primer is used.

So:

- Soil should be applied to the base, cleared of dirt, dust and grease stains;

- The bases intended for finishing should be strong, without peeling sections. If they are, they need to be cleaned and, if necessary, tightened with a leveling solution;

- The joints between sheets of drywall or reinforced concrete panels, as well as large cracks, must be primed before sealing, so that the solution is well kept in them and does not tint;

- Before applying the primer to a surface leveled with plaster or putty, it must be allowed to dry completely.

Note. If the smoothed surface is subject to grinding for finishing, this work is performed before applying the primer, then it will be impossible to do this.

Technical characteristics Primer Concrete Contact can also solve problems such as strengthening the base. For example, it is able to prevent and eliminate dusting of concrete walls, provide a reliable coating for drywall sheetscreating a strong film on their surface.

For best results, Concrete Contact is used in tandem with a deep penetration primer, which is applied in the first layer.

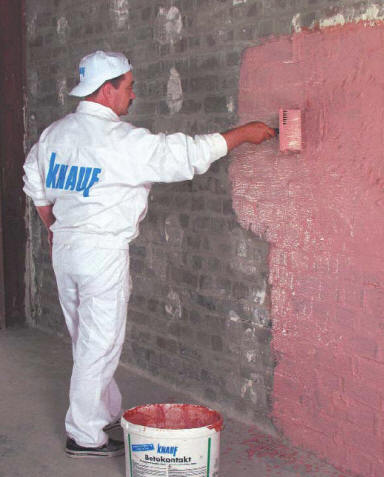

Apply the soil in any convenient way - with a brush, roller, brush or using a spray gun. In its consistency, it looks like ordinary water-soluble paint, so no problems should arise.

As a rule, the product is sold ready to use, it only needs to be thoroughly mixed. But some manufacturers recommend diluting it with water when processing certain surfaces. Proportions are indicated in the instructions.

It also regulates the time of complete drying, which must pass after application to the next stage of decoration, which depends on air temperature. Usually it is at least 3-4 and no more than 12 hours.

Important! Even if after 1-2 hours it seems to you that the surface is completely dry, do not violate the technology and strictly adhere to the manufacturer's recommendations regarding drying time.

On the other hand, do not prime the surface very well in advance. It is advisable to do this on the eve of the subsequent stage of finishing, so that dust does not have time to get on it or moisture gets in - this will reduce the adhesive properties of the prepared base.

You can get acquainted with the technology in more detail by watching the video posted on this page.

Primer Specifications

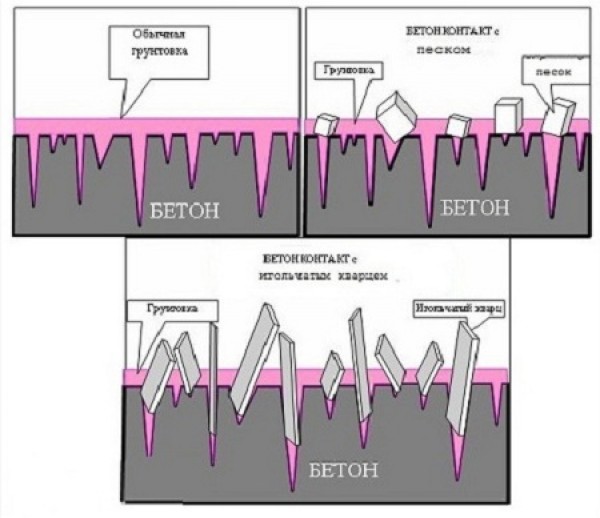

Concrete contact in its composition is a polymer dispersion based on acrylic with abrasive additives that provide surface roughness.

Primer Concrete Contact - material specifications:

- Designed for non-absorbent and poorly absorbent substrates to improve their adhesive properties;

- Has the ability to strengthen the base;

- It is applied for internal works in the heated and unheated rooms;

- It has waterproofing properties, creating a waterproof film on the treated surface;

- Differs in high rates of resistance to alkaline environment;

- Not toxic, does not contain chemicals harmful to health;

- It does not have a pungent odor;

- It is supplied as a ready-to-use pigmented solution in containers from 6 to 40 kg;

- Suitable for both manual application and mechanical spraying.

Documents governing the composition, characteristics and technology of working with the primer Concrete Contact - GOST and the technical conditions adopted at the factory. Therefore, according to some indicators, the compositions of different manufacturers may vary slightly.

One of the most important indicators that you need to pay attention to when buying a Betonocontact primer is the characteristics and consumption rates (seePrimer consumption per 1 m2 - approximate data for determining the required volume) They depend not only on the application method, but also on the material and the absorbency of the surface.

It is clear that the higher it is, the more primer will be spent on its processing. The flow rate is also affected by the fraction of silica sand included in the dispersion.

- The primer with a fraction of 0.3 mm is intended to prepare surfaces for leveling with putty, painting and other types of finishing. It has a rather economical consumption, which when applied by roller or brush will be no more than 200 g / m2and with mechanical spray up to 270 g / m2;

- A primer with a fraction of 0.6 mm is used for plastering and is applied in a thicker layer. Therefore, its consumption can be more than one and a half to two times and amount to 350-400 g / m2.

Conclusion

The price of concrete contact, depending on the manufacturer, can be different, on average it is about 600-700 rubles per 10 kg. This amount is enough to prepare 40-50 square meters of surface.

If we take into account the cost of finishing materials, which can simply fall off and become unusable if you refuse such a technologically important stage of work as priming, then the cost of the primer will be minimal in comparison with it.