Steam room decoration: principal features

Finishing the steam room, this is perhaps the most important and crucial stage in the construction of the bath. The steam room is the heart of the whole structure. This is a place of rest and relaxation.

Therefore, to carry out finishing work is extremely important. This topic will be devoted to our article.

You can watch photos and videos on various materials and make the right choice. The materials that are most suitable for different parts of the structure will be presented.

The content of the article

The main features of the decoration of the bath

At bath decoration There are some nuances that you should know before proceeding with the work. Please note them before starting work.

So:

- All interior decoration begins with the floor. And only after that it is necessary to start arranging the ceiling;

- With the correct execution of the ceiling, you can use the distance to the roof as an attic. Here you can store and inventory.

Then, when finishing, a hatch should also be provided, which should also be hermetically sealed and placed in a convenient place; - For the manufacture of the ceiling, the installation of the first board is especially important. It is along it that the landmark will go in the further manufacture of the structure. If this is not done, then the whole configuration may be violated and you will have to redo everything;

- When installing the lining and fitting it, you should not just beat and drive the element into the groove. This must be done with the lining and a mallet, then you will not damage the surface.

We make the steam room decoration in the bath

This issue should be approached thoroughly and prepared. If you understand this and prepare properly, then you can do all the work yourself and without resorting to an extraneous area.

Let's look at everything in stages, in terms of doing the work.

We make the floor in the steam room

A bathhouse is a building that, first of all, should keep heat as best as possible. Moreover, there is increased humidity, that is, increased demands are placed on floor equipment.

So:

- For the construction of the floor, it is worth using certain types of wood that fully comply with the design of the room. For this, it is best to use hardwood.

This material is quite hard and does not contain resin, which during heating can be harmful to health. The price of this material is much higher from conifers, but it is worth tempting for cheapness;

Attention: when installing the floor, it is extremely important to use wood with a moisture content of not more than 10 percent. If you do not maintain this indicator, then the material will dry out and gaps will appear in the floor.

- When choosing the thickness of the board, it should be borne in mind that thick material is most deformed during expansion. Therefore, it is best to use elements with a thickness of the order of 25 mm.

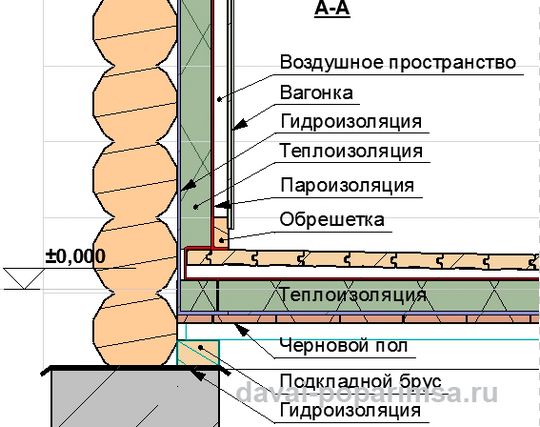

To create additional rigidity, additional lags are installed. And you should choose the sheet pile material. It will give the desired rigidity of the plane; - Do not forget to waterproof the plane. To do this, apply a one-sided membrane, which will make the floor service life much higher;

- Before installing the floor, wood treatment with antiseptics should be done. We will have a humid environment and therefore the material should be protected from the development of fungus and mold;

- Logs should be laid on the foundation of the sense after the isolation, for this they put roofing material.If the lag has a length of more than three meters, then support pillars should be made, otherwise it will begin to bend over time;

- We put logs on the bars, but they should be prepared and cut, making a slope for the drainage of water on the floor;

- After this, it is necessary to lay the waterproofing layer of the material. Only the release of the edges should be on the edge of the order of 20 cm.

We will need this for joining the wall insulation; - After that, the flooring is already done using a grooved board.

Floor Tips

When installing the material, it will be better to listen to some owls of specialists:

- Lay the floor in such a way that water flows across their location;

- The distance from the backfill to the subfloor must be at least 159 mm. This will contribute to normal ventilation and will facilitate the normal outflow of water;

- In order to avoid extraneous noise while moving along the floor, put under the logs glass wool with a thickness of three cm. They should be placed on top of the roofing material;

Wall cladding in the steam room

For the proper operation of the steam room or sauna (seeFinishing a sauna lining: how to do it right) you need to do the right wall decoration. Finishing the steam room should be especially high quality.

There is high humidity and it is necessary to properly concentrate the heat.

So:

- Finishing paired walls is also done using hardwood. For this, lining is used. With its installation, insulation material can also be used.

For high-quality finishes, it is better to use euro lining. It is available only from selected wood.

An enlarged groove is provided, which contributes to a better and better fastening of the elements. Yes, and the quality of the dimensions at a height, you do not need to spend a lot of time on fitting elements.

Most importantly, special grooves are provided in it, through which air circulates better. For the steam room this is a very topical issue;

Attention: Before installation in a pair of lining, in no case should be treated with antiseptics. There is high temperature and humid environment. Therefore, processing you can harm your health.

- First, the crate is applied and then the insulation is attached. Only when doing this work should consider the following.

The insulation should not be pressed against the lining. Make another clearance of the order of two cm.

This will improve air circulation. The pressed and deformed insulation simply loses its qualities; - In the photo you see foil material. Which should be applied. Moreover, the glossy side must be directed inward.

And moreover, this is important, then the heat will be reflected precisely inside the room, which helps to increase thermal insulation. The foil is attached with a construction stapler and the sheets should be overlapped;

Finish the ceiling in the steam room

The right bath is when it saves heat efficiently. The ceiling area is quite large and a lot of this valuable product can go through its plane.

Finishing in the steam rooms in the bath will not be complete without a high-quality processing of the ceiling.

Different materials are used to equip the ceiling in the steam room.

Let's understand the sequence of work:

- For the manufacture of the upper layer, boards are used that go to the attic;

- After that, the insulation layer is installed. Which protects against the penetration of excess moisture;

- After that, the installation of insulation is done. To do this, it is better to use mineral wool.

This material is not heavy and does not significantly increase the weight of the ceiling, and moreover, it is quite easy to attach;

Attention: As a heater, it is not recommended to use natural materials. They easily rot and subside for a short time.

- After the insulation, do not howl to make a vapor barrier layer;

- Now we fasten the slats, they will be required for the last layer of the facing material;

- And the last material is attached to the lining, which will finish the finish of the plane.

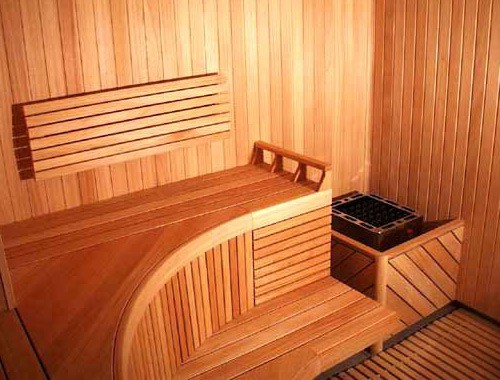

Making shelves in the steam room

This is the most necessary attribute of the steam room. Here you will simply sit or lie and enjoy the sensation of a steamed broom on the body.

Pair finishes are simply inconceivable without this interior attribute.

Of course, this work is better done using hardwood.

For the manufacture, it is worth listening to the advice of the masters:

- Mount wooden elements in such a way that they are not accessible to the human body;

- Do skin the carcass only with a gap of at least one cm. This will ensure normal ventilation;

- You will adjust the height depending on the height of the ceiling. Only advice, in the manufacture of three tiers: make the uppermost tilt, the lower tier preferably removable, and the middle one is simply stationary;

Caution: Do not make the steam room too high a ceiling. Better done with quality.

With an extra floor space, there will only be a poor-quality heating.

- It is believed that the Abashi tree is best suited for the regiments, it is not so cheap. in our strip, it can be replaced by hardwoods such as maple or black alder. Only applied should be well-dried material, otherwise it is strongly deformed;

- Never cover the surfaces with varnishes or other materials. To prevent decay, they now offer a special antiseptic, which is made only from natural ingredients and is suitable for use in a steam room.

Detailed instructions are for performing any work in the bathhouse on the pages of our site, for example, about sink interior. There you can find many useful tips.

The price of the material in this matter should not be very scary, because you are doing everything for your health and comfort.