Material for facing stairs: which is better to choose

The staircase is a supporting structure, constantly exposed to abrasive loads. Therefore, materials for facing stairs should not only differ in decorative qualities, but also be able to withstand these loads for a long time.

We will offer you the most suitable options for facing the stairs in the house, and briefly describe how they are carried out.

The content of the article

Stone staircase design

Stone cladding is the most durable, but not all types of stone are suitable for stairs finishes. Many rocks have a porous structure, and therefore, low abrasion resistance.

It’s not news to anyone that marble and granite are the most durable.

So:

- They are mined in our country, and you can order such a lining in any region. Stairs with onyx and travertine trim are also found, but not so often.

These breeds are rarer, and the price of such a finish will be even higher than with marble - also, incidentally, not cheap.

- Stone for cladding stairs can be made in the form of tiles of a standard size, for example 30 * 30 * 1.5 cm. The steps can be solid, but in this case they are made to order.

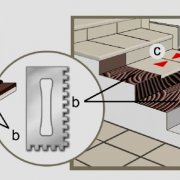

There are no standards here, because the design of the stairs, their size and configuration of the steps is always different. - The installation technology of the cladding elements is different in both cases. The installation of the stone in the form of tiles is carried out in the same way as the facing of the stairs with tiles.

In this case, the most important thing is the correct execution of the edge part of the steps, because they are most exposed to loads.

- The easiest way is if for step finishes tiles with edging overhang are used. In this case, the vertical riser element is first glued, and then the tiles are laid on the tread.

To fix the tiles use glue for stone, which is sold both in dry form and ready. - If the tile does not have an overhang, the staircase is lined with stone using a special profile, which is necessary for the design and protection of the corners of the steps. There are many types of consumables.

The angular profile can be both laid on and mounted inside the structure, under the cladding elements. - The profile not only protects the edges from destruction, but can also have an anti-slip surface. This finish is great for concrete marching stairs, and is perhaps the best option.

- Monolithic steps made of stone are mounted not only on concrete stairsbut also on metal. The installation of heavier stone cladding elements is carried out using anchoring.

Methods for installing anchors can be different. - There is no single recipe here, each master makes a decision, depending on the design of the stairs. Do not use only spacers, such as self-tightening wedge anchors and plastic dowels.

Despite the strength of the stone, cracking the slab is fairly easy. - Grasping the stairs with your own hands, watch the video in advance. You will gather a lot of necessary information for yourself, which no written or oral instruction will give you.

This will allow you to do the job efficiently, without spoiling the expensive material.

- The stone is used not only for decorating steps, but also for the ends of the march, and the grounds. Parapet elements can also be made from it: balusters, railings.

It all depends on the funds that the customer wants to invest in the decoration.

It is impossible not to mention that the chic stone cladding of the stairs requires adequate decoration of the wall along it. The tree is quite worthy adjacent to marble, and you can see this by looking at the photo above.

Laminate as an alternative to wood

The tree of valuable species used for the decoration of stairs is a classic version: elegant and aristocratic.

No one is going to belittle its merits. In fact, such a finish has one drawback - high cost.

So:

- For those who would like to save money, having received a durable cladding with a wood texture, there is a great alternative. This is the facing of the stairs with a laminate - the one that is usually used as a floor covering.

This material does not have special strength, so you need to select it in accordance with the expected loads.

- For facing the stairs in a residential private house, in which one family lives, class 23 is suitable (for halls and hallways). If you get off the stairs in the cottage, where two or three families live, it is better to take a laminate of 31 classes (for small offices).

- For commercial premises with heavy traffic, even more durable versions of laminate flooring are produced: 32 and 33 class.

- Upon purchase, the width of the panels for cladding is selected depending on the width of the steps. The standard size of the treads in the marching stairs is 30 cm.

But there are stairs where the configuration of the steps is triangular, or curved. - In this case, the widest part of the tread is measured. At the same time, it must be borne in mind that its coating must be integral, therefore, the calculation of the required amount of laminate is done based on the total number of steps.

- For facing treads, the laminate can be cut, so just calculate how many of them will be enough for one panel. Let's say three. Divide the number of steps by this number, and add several panels to the stock.

If there are sites that also need to be faced, then the amount of laminate for them is calculated separately. - Cut panels can, of course, and a hacksaw for metal. But if you need to make a cut in length, it is most convenient to use a hand saw.

A curved cut, as well as round holes, for example under balusters, is easier to do with a jigsaw.

- As in the case of stone or tile, the edges of the laminate are closed with a special profile. It is better if it has an anti-slip relief, because the surface of the laminate is very slippery.

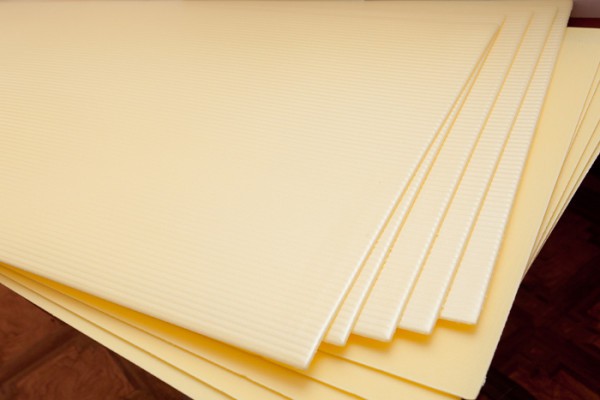

Fasteners in the form of screws and screws, as a rule, are sold complete with a profile. - To lay the laminate, use a backing. It can be a polyethylene film, or a roll cork coating.

The substrate, in this case, plays the role of a shock absorber, sound insulation, and also protects the laminate from premature wear.

To save yourself from the need to perform such painstaking work as installing stone steps, or facing a laminate staircase, you can choose another option. There is a structure used to climb to the second floor, which, perhaps, not everyone knows.

This is a modular staircase, which is assembled from individual elements, like a designer. And then you just have to laminate the floor, or maybe the wall along the span, as was done in our example.