How to paint a cast-iron battery: paint selection, surface preparation and painting technique

Today, with a respected reader, we have to figure out how to paint a cast-iron battery. We will learn what paints can be used for painting, how to prepare the surface of the radiator, and how to apply paint to the prepared surface. Let's get started.

The content of the article

To paint or not to paint

Before we get started, let's find out: is the result of the effort worth it?

Painting is contraindicated

Coloring cast iron batteries is devoid of any meaning in three cases:

- If the radiator (new or standing on the heating for several years) will be closed with a decorative screen or installed in a closed box. Painting performs purely decorative purposes, since cast iron is a corrosion-resistant metal, and an extra coating layer will only reduce heat transfer;

It is worth clarifying: the author is categorically against non-removable screens covering most of the surface of the batteries, and even more so against installing heaters in the deaf boxes. In addition to a sharp drop in heat transfer, the owner also gets serious problems with the availability of connections when eliminating leaks between the sections and on the connections to the heater.

- If the radiator flows between sections. The paint layer will not stop leaking, and rusty streaks will be even more noticeable on the new coating. Before applying a decorative coating, the leak should be eliminated by changing the intersection gaskets or pulling up the nipples;

- If part of the radiator sections does not warm for several years. The reason for this is usually siltation of the extreme sections, and in 10-15 years without washing the sludge acquires the strength of the stone and is removed from the radiator only during annealing, which we will talk about later.

Painting is desirable

In some cases, painting batteries - cast iron or steel - can radically change their appearance?

- If part of the coating has peeled off or has signs of abrasion;

- If the paint turns yellow from prolonged heating;

Reference: a color change is characteristic of paints with zinc whitewash ZnO. Since 2007, their production has been discontinued: zinc oxide has been superseded by more stable and less toxic titanium TiO2 whites.

- If repeated painting of cast-iron heaters on top of the old coating gave untidy influxes.

Paint selection

Now let's find out how to paint cast-iron batteries.

The main condition is the thermal stability of the coating: in a centralized heating system, the temperature of the coolant at peak cold can reach 95 degrees. Compliance of the dye with this requirement is indicated by the inscription “heat-resistant” or “for radiators” on the package.

It is worth clarifying: cast-iron radiators are used not only on water, but also on steam heating. In steam heating systems, the temperature of superheated steam can reach 150-400 degrees Celsius. However, in our time, such systems have been preserved only in industrial conditions, at enterprises of the old construction.

Here are a few examples of the corresponding colors:

| Appearance of packaging and name | Description |

| |

| |

| |

|

Radiator preparation

How to paint batteries - cast iron or steel?

For some manufacturers, instructions for using paints (for example, the last two in our mini-review) directly indicate that they should be applied directly to the metal. And even if this requirement is absent, the old coating needs to be cleaned.

There are three reasons for this:

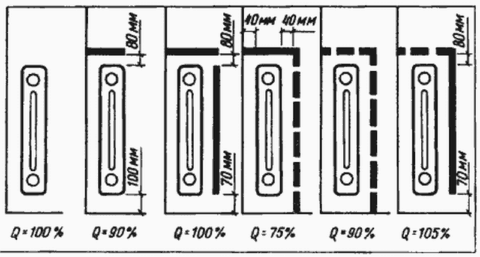

- The thicker the coating, the lower the heat transfer of the radiator;

- Paints are compatible with each other only within the same family: for example, alkyd enamel does not adhere well to a base painted with oil paint. Meanwhile, you do not always know the type of paint applied to the battery during the last repair;

- Old coatings are often decorated with untidy drips, which are better to get rid of.

How to clean old paint with your own hands? Here are a few ways of varying difficulty.

- The front (in sight) surface of the radiator can be cleaned to metal with a metal brush (manual or made in the form of a nozzle for a power tool);

- It is easy to remove the layers of old paint with a spatula, having previously treated the battery with a universal wash and wrapped it in a plastic film for a dozen or two minutes;

- Instead of rinsing, the paint can be softened by heating each section with a hairdryer or blowtorch;

This method has a serious drawback: heating will lead to burnout of the intersection gaskets and the winding of threads on the connection to the radiator. Use a blowtorch or hairdryer is only if you are going to sort out the radiator.

- Finally, the most radical solution is to anneal the battery in a fire. Several dismantled heating devices are lined with wood and ignited for an hour.

In this case, the paint completely burns out on the surface, and petrified deposits of silt inside the vertical channels and collectors turn into scale, which is easy to knock out of the radiator with a rubber or wooden mallet.

Captain Evidence suggests: in this case, after annealing, the cooled radiator is sorted out with the gaskets replaced. Annealed nipples are unscrewed with minimal effort.

If grease or oil stains remain on the surface of the pig-iron battery cleaned from paint, they are removed with any solvent (gasoline, acetone, solvent, etc.). Manufacturers of alkyd enamels usually recommend applying them on the ground; in this case, cast iron is primed with one or two layers of GF-021 glyphtal anticorrosion primer.

Painting

Unless otherwise specified by the paint manufacturer, the heater is painted cold: otherwise, the coating will dry excessively quickly and produce untidy overflows. Tool - a narrow brush or spray gun; in the latter case, the battery must be removed or at least reliably protected from staining the floor and walls by covering them with polyethylene. The paint is applied with at least two thin uniform layers with intermediate drying.

The video in this article will more clearly show you how to paint cast-iron batteries.

Attention: if during the application of the next layer there are streaks on the battery - after drying, grind them, and then apply another layer. Excessively thick (not diluted before use) or a thick layer of paint usually gives drips. Its normal viscosity should correspond to the viscosity of liquid cream.

Conclusion

We hope that our material will help you return your second youth to old heating appliances. Good luck!