Water-based paint: advantages, varieties, application

How practical is water-based paint for interior and exterior home decoration? What water-based dyes does the modern market offer? How to prepare the surface for painting and perform it? Let's get it right.

The content of the article

What it is

Water-dispersion (or, more often, water-based) paints are called for their composition: each of them is a dispersion (suspension of the smallest insoluble droplets) of a synthetic binder with pigments and auxiliary additives in water (see Water-based paint: material features) When the water dries, the droplets stick together and, due to contact with air, undergo polymerization, forming a sufficiently durable coating.

Rating

How does water-emulsion paint look against the background of competing solutions - paints based on organic solvents (acetone, white spirit) and oil?

Benefits

- Complete absence of odor during application and during operation. Paint only saturates the air with water vapor;

- The resulting harmlessness - unlike organic varnishes and drying oils;

Note: on the practical side, this means the possibility of paintwork in the premises without forced ventilation and personal protective equipment. When working with any paints based on organic solvents - both items are required.

- Fire safety. Oil, alkyd and nitro enamels are flammable, and their vapors are explosive. The water base makes it possible to work with paint near an open flame, without fear for its bright future;

- Quick drying (from 15 minutes to 2 hours depending on atmospheric humidity, temperature, texture of the base and thickness of the coating layer). According to this parameter, only nitro enamels approach water emulsions; however, they retain a characteristic odor for several days after the surface “drys off” and even after complete polymerization;

- More than a modest price per kilogram (from 30 rubles). For obvious reasons, water is cheaper than drying oil, acetone or solvent.

disadvantages

There are not so many of them, and unpleasant features of water emulsions are manifested in rather specific conditions.

- Limited compatibility with other coatings (in particular, most waterborne paints will not lie on alkyd enamel or oil paint);

However: this fully applies to all other dyes. Paints of the PF family cannot be used without cleaning the base from the coating of the MA family, and nitro enamel will not lie on the pentaphthalic.

- Wear resistance and strength inferior to two-component paints based on organic solvents. Those are designed specifically for surfaces that undergo intensive wear during operation.

What are they

Let's agree that we will limit our acquaintance with varieties of water dyes to the area of decoration. Application and production of water-based paints for metal, plastic, etc. will remain behind the scenes: a review of all modern dyes is too extensive a topic for a small article.

Read also:What are the types of water-based paints.

Mineral

The bonding base is cement (usually white) or lime.

Scope - internal work. Mineral paints are used on the following types of surfaces:

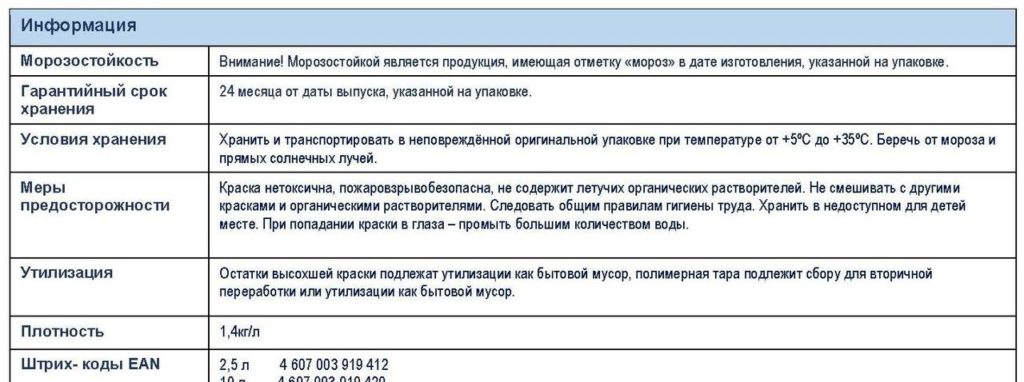

| Picture | Type of surface for painting |

| Monolithic and panel concrete walls | |

| Brick walls | |

| Plastered surfaces |

Features - durability of the coating, limited resistance to moisture, low wear resistance.

Silicate

The bonding base is potassium or sodium liquid glass (also known as clerical glue). A scope - internal works on the mineral bases, painting of facades. Features - moderate moisture resistance, long service life (up to 20 years in air), low resistance to dry and wet wear.

Acrylic

The bonding base is acrylic resins. Scope - external and internal work on any wettable substrates.

Features:

- Moisture resistance - moderate to high;

- Life time - from 5 years in atmospheric conditions to 15-20 years in a dry room;

- Resistance to dry wear - high (rubbing the wall with your hand, you will see a completely clean palm);

- Resistance to wet wear - medium (when cleaning with a damp sponge, the paint leaves traces on it).

Latex

The bonding base is synthetic latex. Scopes: external and internal works on any bases wetted with water.

Features:

- Increased moisture resistance (in particular, the so-called rubber waterproofing paints are made on the basis of acrylic synthetic latex);

- High resistance to dry and wet wear (the coating can be washed using non-abrasive cleaners);

- High elasticity (latex paint can hide cracks and cavities up to a millimeter in size).

Silicone

The bonding base is silicone. Scopes - external and internal works on any bases wetted by water.

Features:

- Absolute resistance to moisture - the coating can endure long-term contact with water without damage to itself;

- Elasticity: the paint layer tolerates minor deformations of the base, and is able to hide surface defects up to 2 mm in size;

- Resistance to abrasion, including wet: the surface, according to the manufacturers, tolerates up to 5000 cleaning cycles.

How to paint

How is water-painting of walls and ceilings done with your own hands?

Read also:

The video in this article will more clearly show you how water paint is applied.

Base

It should be:

- Equal. Defects obviously will not decorate your walls;

Useful: dyes with a glossy texture emphasizing the slightest irregularities are especially sensitive to the quality of the substrate. Matte paints, by contrast, hide minor fillings and polishing flaws.

- Moderately absorbent. Excessive absorption will increase paint consumption, and on a smooth glossy surface, that, simply, will collect in drops;

- Clean. A layer of dust will prevent adhesion of the finishing coat to the base, and grease and oil stains will not allow the paint to soak;

- Durable. Retarded or crumbling plaster means that the painted surface will be irreparably damaged by any mechanical impact.

Here is a typical wall preparation procedure:

- It is cleaned with a hard spatula from lagging coatings and weak plaster;

- Irregularities (in the most advanced cases - the entire surface of the wall) are putty and polished;

- The dust remaining from grinding is swept away or removed with a vacuum cleaner;

- The wall is primed for painting. The primer strengthens the surface, binds residual dust and reduces the absorbency of the wall or ceiling, reducing paint consumption.

Please note: instructions for choosing a particular primer are always given by the manufacturer on the packaging or on its official website. Usually, primer is used based on the same binder as the paint (latex for latex paint, silicone for silicone). The most versatile acrylic penetrating primers.

Paint preparation

During storage, the dye exfoliates, so before use it must be mixed throughout the entire volume with a stick or drill with a whisk. If the paint has thickened or will be applied with a spray gun, it must be diluted with water (not more than 10 volume percent).

Manual tinting in the desired color is performed immediately throughout the volume: when re-mixing the dye with the pigment, you are unlikely to get the same shade.

Tip: keep a small supply of tinted paint in case you accidentally damage the wall and repair it.

Application

The author uses the most primitive set of tools for painting with water-based paints:

- Brush for painting the internal corners and problem areas (adjacencies to the floor, unpainted finish elements, sockets, etc.);

- Roller with medium pile;

- Paint tray.

In addition: masking tape will help you protect what you are not going to paint - the edges of the built-in furniture, ceiling skirting boards, etc.

Here are the basic rules for painting:

- Paint should not be thick. Two thin layers dry faster than one thick. In addition, a thick layer of paint often smudges;

- The lower limit of temperature during painting is +5 - +8 degrees. Upper - +30: in more intense heat, the walls will dry out before you evenly distribute the dye on their surface;

- First, paint over the problem areas with a brush, then work on the planes with a roller;

- Paint a wall or ceiling plane in one go. Take a break - get an influx at the border of the dried up area;

- Apply layers perpendicular to each other. So you hide the stripes from the brush and roller;

- The last layer should lie in the same direction in which the surface is illuminated by the brightest light source. The goal is again to make the strips invisible;

- Drywall paint at least a couple of weeks after filling the joints. If you hurry, the seams will stand out in a dark shade: they do not have time to complete the process of hydration of gypsum.

Conclusion

We hope that our simple tips will help the reader choose the best solution for decorating their home. Good luck!