Porcelain cladding: laying technology

At the moment, it has become increasingly popular to use natural stone or ceramic tiles in interior and exterior decoration. By their properties, these materials may be somewhat similar, but the methods for their use are quite different.

For example, granite cladding technology will be different from porcelain stoneware technology.

The content of the article

Porcelain and granite: which is better?

These two types of material can be used in both exterior and interior decorating.. They have almost the same properties and technical indicators.

Distinctive features:

- It cannot be said that any of them will be better or worse. It all depends on the type of work performed and on the surface on which the material will be mounted.

- As a rule, granite is used to decorate the building outside or for the construction of decorative fences. Porcelain tile is suitable for finishing work on basement house and for the manufacture of garden paths and other things.

Both granite and porcelain stoneware are very reliable materials. In the photo there are examples of both that and that material.

Granite its properties and advantages

Granite is a natural stonethat is mined from the rock. It is environmentally friendly.

But there are some nuances. Environmental friendliness depends on the region in which mining is performed.

In some cases, a stone can radiate radiation and it is not recommended to use it for decorating a home.

Tip. Before buying natural stone, it is always necessary to pay special attention to the documentation for this material. He must pass the test for radioactivity and only after that a certificate of environmental friendliness is issued.

Material Features:

- Since the stone is natural, then the price for it will be rather big. This is the only disadvantage of granite.

- It is used not only in the decoration of the room, but also for the design of a variety of decorative elements of the room.

- For example, kitchen worktops, fireplaces, stoves (seePorcelain stoneware lining: finishing steps), the surface of the walls of the room, which is decorated in a classic style and so on.

- In its structure, it is full-crystalline and may contain a variety of colored pigments of natural origin of various shapes.

The color of the material itself is also diverse, there are:

- Red.

- The black.

- White.

- Gray.

- Green granite and so on.

So:

- In coloration, as in direct formation, an important part is played by an integral part of the stone structure - feldspar.

- The surface of the material has insignificant pores, which makes it impossible to use stone for finishing rather “dirty” rooms, for example, fast-food establishments, which have a very high percentage of traffic.

- Dirt seeps easily into these pores, and it is quite difficult to remove it from the surface.

Granite has the following properties:

- Environmental friendliness, since it is of natural origin and after extraction is not subject to additional processing.

- Moisture resistance, the surface of the stone is not able to absorb moisture, despite the small pores on it.

- Strength. The stone can withstand a very large physical or mechanical impact and at the same time not be deformed.

- Wear resistance - the appearance of granite and the color that was originally inherent in it do not change over time.

- Durability - stone can be exploited for 50 years.

- Frost resistance - maintains low temperature conditions and at the same time its structure is not deformed.

- Practicality - granite does not require special care and the surface is easily cleaned with a damp rag.

- If the stone is already mounted on the surface, then it has high impact resistance. Himself

- granite itself is quite fragile.

- It may be a material in the form of a simple stone, which is used for cladding buildings. They lay the wall and fences.

And there is another type of granite-tile. The range of its application is much larger than that of a simple stone. - Ordinary granite that has irregular shapes is called rubble stone. It does not burn and does not melt under the influence of high temperature conditions. Under the influence of the sun does not fade and does not deform.

Note. Granite cladding technology may depend on the type of material itself. The size and weight of the stone, which is not too small, also play a large role.

Use and installation of rubble granite stone

The technology of granite cladding using rubble stone is very similar in principle to using brick or any other building material. Masonry of rubble stone depends on its size and shape itself.

Tip. When installing rubble granite stone, it is worth considering that not every form of stone will fall normally on the previous one. Here, all actions are performed by the method of selection and size and shape.

Areas of use:

- They can be lined with the wall of a residential building, but do not forget that the lining should be connected with the wall of the building.

- For this reason, reinforcement is initially mounted on the surface, the rods of which will pass between the stones and be fixed there.

For the installation of rubble stone you will need:

- Mortar of concrete, which consists of sand, water and cement of high strength. In rare cases, hardeners are used, which are added to the solution during its preparation.

- Master OK. The choice of such a tool is more dependent on the ease of use.

- Construction level so that the wall can be laid out evenly.

The technology of wall cladding with granite can be using bridging.

What it is:

- In the process of masonry, a solution is used that has a certain shade. How it's done? Everything is pretty simple.

- A coloring pigment of the required shade is added to the solution and with its help stone laying is carried out.

- In order to ensure the uniformity of the color of the solution, it will be necessary to clearly calculate the amount of coloring pigment for the same weight of the concrete solution.

Tip. To avoid this, you can use a special tool that has the shape of a tube to squeeze the solution into the joints after the stone is installed. This will help to save money and reduce the consumption of coloring pigment.

- It is worth considering that under this type of cladding you will definitely need to make a foundation. It can be common with the main one for the house itself, or it can be separate, which has a certain connection with the main foundation.

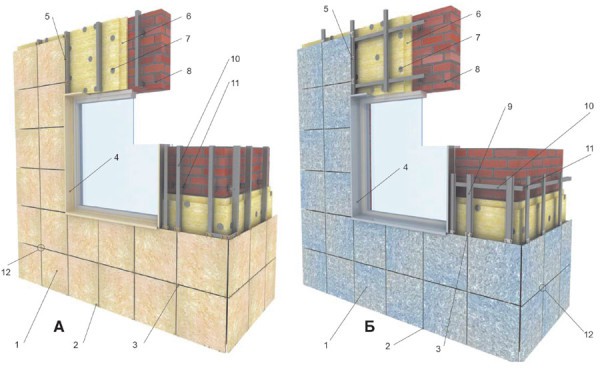

- During the cladding, it will be possible to carry out insulation and insulation of the building with the help of modern materials that are mounted on the walls of the house and granite is already mounted at a certain distance on top of them.

- This is a ventilation gap, which will protect the house from moisture and in a timely manner will eliminate excess moisture. There is a special instruction for this, according to which the necessary distance of the finish from the wall of the building is determined and so on.

Note.

Facing walls with granite is not a very complicated technology, but requires a special approach. The main task will be to correctly select the normal shape of the stone in order to quickly mount it.

Surface mounted granite slab

As a rule, facing with granite slabs technology implies installation only on a flat surface. This is due to the fact that in most cases the surface of the plate and its back side are even.

Tip. If the surface does not have a flat plane, it will be better to align it before installing the material. If it is not too uneven, then in the process of fixing the tiles, you can level it using concrete mortar.

Stages of work:

- It is best to perform surface leveling operations only with cement mortar. All this is due to the fact that the stone does not have a small mass and only a solution of high strength can withstand such a load.

- You can use both plaster and drywall, but this is only if the size and thickness of the plate is small. Otherwise, there is the possibility of delamination of the finish and its deformation.

- The technology of facing with a granite slab implies not only leveling the surface, but also its strengthening. To do this, a reinforcing wire mesh is attached to the surface of the concrete mortar, which will give strength to the finish.

For the installation of granite tiles you will need:

- Concrete mortar or adhesive mortar, which is intended for the installation of natural stone.

- Metal spatula.

- Building level.

Ways:

- You can also use a decorative seam during installation. All actions are similar to installation ceramic tiles, only here you can not use cross-shaped beacons, which provide an even distance between the plates.

Installation is carried out in an arbitrary style, since the material itself does not have clearly defined dimensions. - The technology of facing with granite slabs will depend more on the size of the material. But it is best to start installation from below and only then move to the side until the first row is completely laid.

Then it takes time for the tile to fix well on the surface. Further it is already possible to lay subsequent rows of granite slabs.

Note. Porcelain cladding technology will have similar actions and tools, tools.

Watch the video for an example of installing granite tiles.

Porcelain tile and its properties, methods and technologies for use

This type of ceramic tile comes with the addition of feldspar in the structure, which is the main component of granite. From this came the name - granite.

Features:

- It has the same properties as ceramic tiles, only the strength of this material is much higher. On the surface, porcelain stoneware can have a variety of designs.

There are also imitations of masonry of natural stone, brick and other things. - The price of porcelain stoneware is higher than that of ordinary ceramic tiles, but if you correctly evaluate the quality and properties of the material, then it will seem very low.

- The routing for porcelain stoneware cladding will be similar to that for mounting simple granite or ceramic tiles. You will also need to level the surface, and use a solution of concrete.

But there is another tool with which you can securely fix the material to the surface - cement-based adhesive.

All actions can be done with your own hands and not make much effort.