Wall decoration with OSB slabs and roofing

Multifunctional, convenient materials for many construction works, you can see in the photo and video, oriented oriented chipboards. The simple manufacturing technology allows us to produce OSB for the interior decoration of four types of basic and three special types of plates.

Flat fragments of the geometric shape of wood chips or shavings are glued layer by layer into the sheets of products. The optimal number of layers of chips or chips ranges from three to four.

These plates are better than conventional chipboards, or rather, they are their modified, modern version. If the tools allow, and technical tasks require their application, then OSB is preferable to materials such as chipboard or plywood.

The content of the article

Classification and area of use of plates

Considering the qualifications and deciding what to finish the walls with OSB, you should pay attention to the characteristics of the plates.

So:

- OSB boards, characterized by their application and use in low humidity environments, belong to the first class.

- The second type of materials is suitable for use as structural elements for construction in dry rooms.

- The third type of qualification is used for the manufacture of structures in high humidity.

- The fourth type of product is the installation of structures that can withstand significant mechanical stress in humid conditions.

OSB boards are used in construction very extensively. Manufacturing technology eliminates internal defects inherent in chipboard sheets (uneven filling or voids), which prevents OSB boards from shrinking or deforming.

So:

- Wall decoration from OSB will not only protect the house from dampness and heat insulation, but will also minimize additional finishing work.

- Moisture-resistant OSB board is used in the construction of frame-panel houses.

- Its moisture resistance allows the use of reusable formwork from this material.

- It is used as a base for exterior wall cladding and for interior work in the decoration of suburban, wooden houses from logs, timber and cottages.

- The device of the lathing and the rafters for the roof do not do without OSB plates. They are able to work under significant load and withstand the weight of the roof itself, even from natural tiles, snow, wind.

- Do you need to lay floors or level them? The OSB board is again being used, creating an even, solid base for plank floorboards, coatings or carpets.

An important point is the adjustment of the joints of the plates along the plane, they need to be equalized if necessary.

Caution: Not all manufacturers OSB boards can be used as underlays for flooring, and panels are laid with the smooth side up immediately before the flooring.

- In addition, it is not necessary to cover the plates with protective varnish or paints, because it is sufficiently protected by special impregnation.

- Processing the slab is no more difficult than processing the wood; nails and screws are excellent in it. OSB plates are not susceptible to decay and are not affected by fungus, in addition, they have good decorative qualities.

- OSB panels are successfully used for furniture production, being an excellent substitute for natural wood, but the price of products from OSB panels is much lower.

- A sufficiently small weight of the material is convenient when decorating or painting with your own hands and construction work

How to speed up the home decoration process

Understand the desires of people involved in the construction of their own frame houseswho are eager to enter their own, separate, separate from the dear neighbors corner. A logical question arises, but is it possible not to do a rough sheathing and do fixing the finishing materials directly on the frame racks?

The instruction manual contains recommendations and an explanation of why this cannot be done. To keep the house warm, it must be insulated.

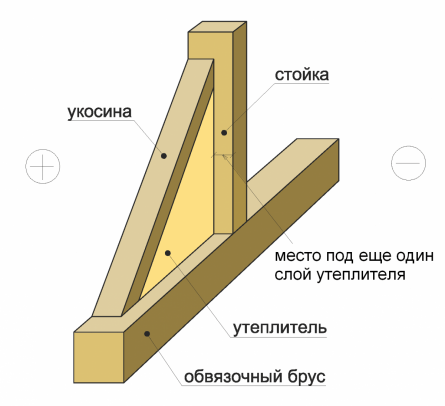

The upper and lower slopes of the frame together with the skin form spatial rigidity, and they are indispensable elements in the design of frame houses. Without mowing, the frame retains its mobility even with mantling, as well as with mowing, but without mantling, you can imagine the overall picture of the consequences yourself, including imagination.

Rough exterior wall cladding

There are a lot of materials used for roughing, and there are plenty to choose from. Board, LSU, DSP and OSB boards.

All these surfaces require a fine finish. siding, stucco with a layer of foam or mesh. Some advise to leave the covering with the board in the role of finishing, but then additional processing of wood is required, and even the device of wind-hydro protection of the walls under the boards.

Attention: It is not recommended to finish the board with the frame without preliminary roughing with OSB boards, in order to avoid unscrewing the boards in spring and autumn, and to give the frame spatial stiffness.

The area of sheets of OSB allows you to get fewer joints than when working with other materials, OSB finish is applied with a thickness of 10-12 mm.

So:

- OSB boards are attached to the racks so that the joint is in the middle and there is a gap of 3-5 mm between them.

- The lower harness is completely covered by a sheet.

- The upper harness is tied to the number of storeys of the house. It is completely hidden and the edge of the OSB plate is aligned with the edge of the trim if the building has one floor.

With a two-story building, the sheet is positioned so that it goes onto the racks of both floors, but the upper binding is overlapped by the approximate middle of the sheet. This is not a prerequisite, but when it is performed, the design acquires additional rigidity.

- Finishing osb boards attached to window opening in a two-story house, it is better to perform a whole sheet to make the joints outside the racks of the aperture to adjacent racks. A window opening cuts into the slab.

- Convenient joining of the plates is obtained by performing additional vertical or horizontal jumpers in the frame with the same cross section as the racks.

- Fastening is carried out with spiral nails, self-cuts of 4.5 mm and a length of 50 mm, you can use combined fasteners with self-cuts and nails.

The main thing is to follow the basic rules for the production of fasteners:

- In the intermediate sections, the osb plate finish is fixed after 30 cm.

- Places for joining plates are fixed after 15 cm.

- The outer edge is stitched after 10 cm.

Attention: In order not to get a plate cracked from hard fasteners, the distance from the edge of the product to the place of fixation is 8-10 mm.

- A gap of 3-5 mm is left between the plates so that they are not distorted and the fasteners are pushed into the rack by 40-50 mm.

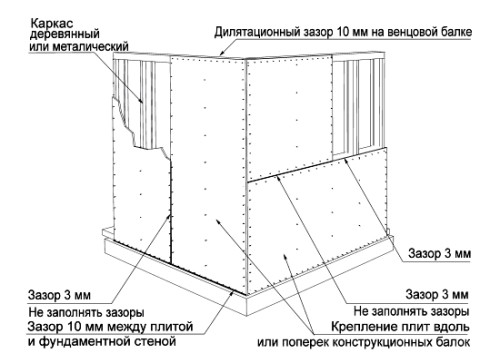

- The vulnerable part of the OSB plate or its “Achilles heel” is at the ends. To protect them, expansion gaps are provided between the upper edge and the crown beam, the lower and foundation walls of 1 cm, between plates where there is no groove-groove for connection of 0.3 cm.

Acrylic sealant is used to process dilatation gaps, which should evenly fill all cavities. - Superdiffusion membrane, having the property of vapor permeability from 800 g / m² per day or more, in this design should fulfill the function of waterproofing and wind protection. The use of films, polyethylene, glassine is undesirable, due to low vapor permeability, and excess moisture must be weathered.

Superdiffusion membrane is located depending on rough sewing with materials and final finishing with products. The membrane is attached to the racks of the frame to the insulation close.

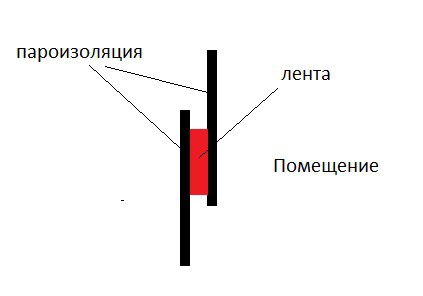

The crate is arranged with 20x50 or 30x50 mm wooden battens, it allows you to get the necessary clearance, then the OSB boards, DSP, LSU or board are finished. - The vapor barrier of the walls is carried out with a film from the inside of the room, it is located close to the insulation, fastened with a construction stapler. Docking is done with an overlap of 10-15 cm. And the joints are glued with tape.

It’s not construction ordinary tape used, but a special double-sided adhesive tape for vapor barrier. - The vapor barrier can also be made with foamed, foil polyethylene that does not thicken the main thermal insulation of the wall.

Interior decoration

How to finish the slab Osbili give preference to drywall with internal sewing of the walls of the house. The dispute is won by the OSB plate.

The frame racks are difficult to maintain when working in perfectly even condition and drywall, as a softer material compared to the OSB plate, accepts these irregularities and, in order to obtain an ideal surface, it is necessary to apply more layers for leveling. The OSB plate is much stiffer in structure and allows you to somewhat smooth out the flaws.

Further finishing is carried out.

Roofing work with OSB-3 plates

The most common way to use this material in roofing works. The optimum thickness is 18 mm for covering the roof with OSB-3 boards.

So:

- Products can have either a flat or castle edge, it is preferable.

- The distance between the load-bearing beams should not be more than 610 mm, both when creating flat and sloping roofs.

- The possibility of expanding the plates is important, therefore, gaps per linear meter of no more than 2 mm are left.

- When laying slabs with smooth edges, 3 mm gaps are provided around the perimeter of each slab.

- Fastening is carried out with nails to supporting supports with a distance between them of 100 mm or more.

- The finish of the OSB slabs is fastened with nails, the length of which should be 2.5 thicknesses of the slab or slightly more.

For OSB panel interiors, the requirements regarding the use of water-based products are applicable. A plate of polished panels looks better when the appearance plays a noticeable role in the interior.

Manufacturers recommend not using wallpaper or ceramic tiles for their decoration.