PENOPLEX COMFORT® and PENOPLEX®WALL - difference on the surface

Two heaters made of extruded polystyrene foam with the same technical characteristics PENOPLEX®STENA and PENOPLEX COMFORT® have an important difference when comparing, which determines their field of application.

The content of the article

Same properties

PENOPLEX COMFORT® and PENOPLEX®STEN have the same physicochemical properties:

- Both of them are distinguished by high heat-shielding characteristics - their thermal conductivity coefficient, not exceeding 0.034 W / m • K, is significantly lower than that of the vast majority of heat insulators from other materials. Thus, to insulate the same room, the layer of PENOPLEX COMFORT® or PENOPLEX®WALL plates will be much thinner than the layer of mineral wool or foam.

- The second important property of PENOPLEX COMFORT® and PENOPLEX®STEN heat-insulating boards is zero water absorption, due to which they keep the thermal conductivity unchanged, since they do not let water into their structure and thereby prevent it from increasing thermal conductivity. This property also does not give rise to the development of bacteria, mold, fungus and other harmful living creatures, which reproduce only in the aquatic environment.

- Both heaters have compressive strength at 10% deformation of at least 0.15 MPa. PENOPLEX® (or “penoplex”), like all other heaters of this manufacturer, are made of the same general-purpose polystyrene, which is used in the manufacture of packaging for food and medical products, as well as children's toys.

- PENOPLEX®WALL and PENOPLEX COMFORT® do not contain harmful and toxic components, so they are environmentally friendly. Plates are painted in orange color, which emphasizes the purity and environmental friendliness of the material.

- PENOPLEX®WALL and PENOPLEX COMFORT® have the same geometric configuration: the end L-shaped edges during the installation of the plates provide a tight joint and the absence of voids that violate the thermal insulation layer.

Thus, many of the physicochemical properties of PENOPLEX COMFORT® or PENOPLEX®STEN heaters when compared give them significant advantages over other heat-insulating materials. At the same time, there is a significant difference between the two of them, which delimits the areas of their application.

Different surfaces

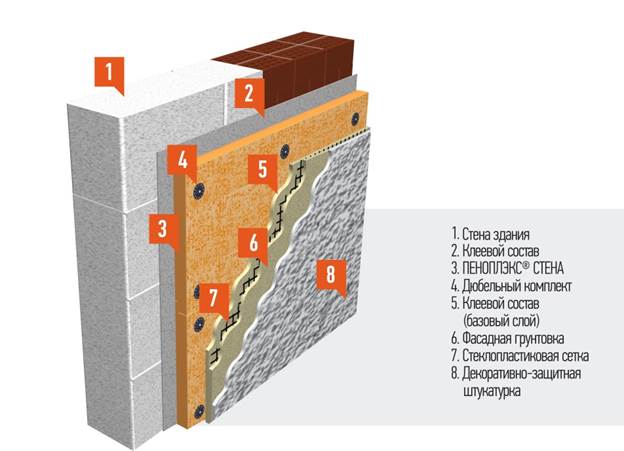

On the PENOPLEX COMFORT® plate, both surfaces are smooth, on the PENOPLEX® WALL one is rough - during the production process it is milled. This is necessary for finishing the insulated wall with plaster materials and tiles. If the heat-insulating board is attached to the wall for reliability with both adhesive (preferably PENOPLEX®FASTFIX®) and self-tapping screws on the wall plugs, mechanical fixing is not possible for plastering and tile application (see diagram below).

Outside, a base adhesive is applied to the surface of the slab, into which the reinforcing mesh is then embedded. This layer dries, then it is primed, and a finishing layer of decorative-protective plaster is applied to the primer. What forces can keep such a multilayer finish? Surface adhesion (adhesion) of the heat-insulating board with the base adhesive. The adhesion to a smooth surface is insufficient, the finishing layers may fall off.

Studies in the laboratories of Moscow State University of Civil Engineering (MGSU) showed that the adhesion of the rough surface of the PENOPLEX® WALL boards with the base adhesive composition is 1.5 times higher than that of polystyrene and 2.5 times higher than that of mineral wool. Moreover, this is three times higher than the technical requirements for the use of basic adhesives.

Compare applications

Thus, the difference between PENOPLEX®WALL and PENOPLEX COMFORT® is reflected in their application:

- The presence of the rough surface of the PENOPLEX®WALL boards determines the scope of their use - wall insulation with stucco and facade tiles. In this case, we are talking about both external insulation with subsequent decoration of the facade, and internal. Many people prefer interior decoration with decorative stucco mixtures with their richness of textures and color schemes.

- PENOPLEX COMFORT® has a wider scope. This brand is designed to create comfort in an apartment or house and is used for thermal insulation of balconies / loggias, pitched roofs, underfloor heating with a small load and the walls of the apartment without subsequent finishing with plaster or tile.

However, PENOPLEX COMFORT® can be used in the same place as PENOPLEX® WALL boards. You can prepare the material for applying the plaster composition with your own hands. To do this, immediately before installation, notches are applied to the PENOPLEX COMFORT® boards to improve adhesion. But it is advisable to purchase a specialized slab, which is prepared for plastering in the factory.

Tags: heat insulating material, thermal insulation, warming