Ready plaster for facade decoration

Ready plaster - a material that does not need to be prepared. The product is used immediately after opening the package. The tool has many advantages over dry mixes, but it also has disadvantages. One of the types of such products is finished facade plaster. The material is used to decorate the surface. Due to its composition, the facade of the building becomes attractive. The main thing is to choose the right product and follow the rules for applying plaster.

The content of the article

Material Description

Plaster mixes ready for exterior decoration create an unusual texture on the surface. Popular remedies are “bark beetle”, “pebbles” and “fur coat”. If white material was used, then after hardening the surface is painted in any color.

Ready-made plaster mixes for exterior decoration are applied in a thin layer. Before applying the material, the surface does not need to be carefully leveled. Small differences are allowed, since decorative plaster will hide defects. The drying speed of most products is 1-2 days.

Characteristics

Ready-mix plaster for the facade has the following characteristics:

- elasticity, due to which no cracks appear on the surface after drying of the material;

- moisture resistance, which makes the product immune to precipitation;

- increased strength and resistance to mechanical stress;

- frost resistance;

- resistance to temperature changes even in the event of sudden changes;

- immunity to ultraviolet radiation.

Advantages and disadvantages

Ready to use stucco for exterior decoration has both advantages and disadvantages. Advantages of the product:

- does not need preparation, which eliminates the need to purchase an industrial mixer or drill with a mixer nozzle;

- minimum consumption per 1 m2;

- creates an original texture on the surface, which improves the appearance of the facade of the building;

- provides soundproofing of the room;

- creates favorable climatic conditions inside the building due to protection against wind from frost;

- suitable for use on the facade and inside the building, as well as in rooms with high humidity, which include the bathroom and pool;

- ecological purity of the composition;

- long operational period.

The finished stucco mixture for exterior decoration also has disadvantages:

- the use of the material requires strict observance of certain climatic conditions;

- high price;

- Finishing requires a few kilograms of funds more than what is in the package, which entails additional costs.

Types of materials

Finished facade plaster is represented by several types:

- Acrylic Such a tool is resistant to mold and mildew and is not afraid of sudden changes in temperature. Other material properties are vapor permeability and water resistance. It is allowed to tint the product after solidification, but the shade will differ from the declared option. The disadvantage is that it attracts pollution.

- Silicate. Contains potassium glass and mineral additives. Such material has moisture resistance, and also frees the building base from excess fluid. The product is easy to apply, does not crack after hardening and repels dirt. The disadvantage is the high cost.

- SiliconeIt has moisture resistance, increased strength and vapor permeability. The material is easy to apply and does not crack after hardening.

- Mosaic. This is a new type of plaster. The composition contains small particles of marble, granite and other stones. Such a tool forms a volumetric texture with various shades on the surface, which creates a mosaic effect.

Selection rules

Finished decorative plaster is presented on the market by several manufacturers. To make the right choice, you must adhere to the following material criteria:

- Vapor permeability. This property suggests that the material allows air to circulate, which prevents the formation of fungus and mold under the material.

- Ease of use. Professionals recommend purchasing those products that process the maximum surface area in one capture of the product.

- The size of the fractions. To create a beautiful texture on the surface, the craftsmen advise you to choose a product that contains particles with dimensions greater than 2 mm.

- Duration of use after opening the package. The longer the use of the composition, the better.

- Type of invoice. In this case, it is recommended to focus on personal preferences. Some people prefer the bark beetle, others prefer a fur coat (as in the photo below).

- Environmental conditions when using the material. Most plasters are recommended for use at temperatures between 15 and 25.0C, if there is no rain outside. If the master plans to finish in other weather conditions, it is recommended to purchase specialized plaster. In particular, silicone products. However, such material will cost several times more than a simple ready-made decorative plaster.

- Attraction or repulsion of pollution. If the house is located near the carriageway, it is not recommended to use acrylic to decorate the facade. Such plaster attracts dirt, which will soon lead to a loss of finish of visual appeal. It is recommended that you select a material that repels contamination.

- Possibility of tinting. If painting is planned after plastering the surface, it is recommended to choose a tool that allows this type of decoration to be performed.

Cost

The cost of the material depends on the manufacturer, composition, texture and weight of the package. For example, acrylic plaster from the company Tserizit with the invoice “bark beetle” and “fur coat” costs an average of 2000 rubles per 25 kg bucket. On the shelves of stores presented materials and higher cost, which does not mean the quality of the product. It is recommended to pay attention not to the price, but to the characteristics of the product.

How to prepare the material with your own hands?

Material for the finishing part of the surface outside the building does not have to be purchased. The manufacture of facade plaster can be done independently. This will require the following components:

- cement - 10 kg;

- sand - 20 kg;

- lime - 10 kg;

- liquid glass - 50% by weight of the finished product;

- water - until the solution reaches the desired consistency.

Do-it-yourself decorative plaster production begins with a combination of sand, lime and cement. Next, liquid glass and water are added to the mass and the solution is kneaded using an industrial mixer. The viability of the finished product is 40 minutes. During this time, the tool is completely consumed.

Material application

The application of the product depends on the type of material. The application of products combines one thing - surface preparation. Ready plaster on gypsum board or any other building base is not applied to an unprepared base. Such material does not mask defects and does not equalize large surface differences. The product only slightly corrects imperfections.For this reason, before using the material, the building base is cleaned and plastered with a starting mortar. Only after the final hardening of the product is the surface decorated.

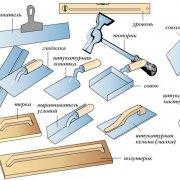

Instructions for applying the product are indicated on the package. Typically, the product is applied with a spatula and wiped with an industrial grater. After solidification of the material, staining is performed if necessary.

The video in this article demonstrates how to apply ready-made decorative plaster to the building facade.

Ready plaster for slopes and other surfaces requires compliance with the rules of application. Only this guarantees the quality of finish and a long operational period of the material without loss of external attractiveness.