Improved plaster

Improved wall plastering is not a type of material, but a way of plastering a building foundation. However, to perform this type of finish, requirements are also imposed on the solution. In order to independently perform improved plastering of a building foundation, it is recommended that you familiarize yourself with all the parameters and nuances, as well as the technology of applying the composition.

The content of the article

Types of surface plastering

There are three ways to perform this type of finish: the plaster is simple, improved, high-quality. Each option has its purpose.

Simple plastering is performed in rooms in which the external attractiveness of the finish is unimportant: warehouses, garages, attics, utility rooms and basements.

Improved plastering is carried out in residential premises, as well as for building facades. In this case, the main thing is to choose the appropriate material for the finish, since not every product is suitable for outdoor use.

High-quality plastering is carried out with the goal of perfect leveling of the building foundation. Such decoration is carried out in public buildings for cultural purposes. However, if desired, high-quality plastering can be done in the living room and for the facade of the building.

What is improved plaster?

What is improved stucco is a common question among lay people. This is a surface finish for leveling, which is performed in three layers: spray, soil and nakryvka. The plaster is applied using guides as a rule. After coating, the material is wiped and the surface is decorated.

To perform improved plastering, it is recommended to choose the right material and prepare the mortar. The application technique must also be followed.

Distinctive features

The difference between improved plaster from high-quality and simple is as follows:

- The number of tolerances is greater than a high-quality finish, but less than a high-quality.

- The thickness of the improved wall plaster is 15 mm. For simple plastering, this indicator is 12 mm, for high-quality - 20 mm.

- The technology for performing improved plaster differs from other types of finishes. For example, simple plastering is performed in one layer without leveling, and advanced - in three layers with the obligatory use of the rule.

Benefits

Improved plaster has the following advantages:

- long period of operation;

- leveling the building base and eliminating surface imperfections;

- resistance to mechanical stress;

- resistance to moisture and other environmental manifestations if cement material is used for decoration;

- fire resistance.

Composition Requirements

Improved wall plastering is done with cement material. According to the regulations, the product must contain PVA glue. This component binds the remaining elements of the composition - sand and cement.

All substances contained in the product must be of high quality. For the preparation of the solution, sand washed from ponds is not suitable, the necessary material is dug out of the ground.The price of such a product is more expensive than usual, but this is a prerequisite for performing high-quality plastering of a building foundation.

Cement is also subject to special requirements. For this type of finish, only a product stored in appropriate conditions, that is, in a dry room on wooden pallets, is suitable. It is recommended to choose Portland cement grade M400 or M500.

Fields of application

Improved wall plastering is carried out inside dry rooms, as well as in rooms with high humidity. This method of decoration can be used for building facades. Improved plaster is most often performed for facing decorative architectural elements: cornices, columns.

Solution preparation

Material for improved plastering can be prepared with your own hands. This will require:

- cement - 1 part;

- sand - 3 parts;

- PVA glue - at the rate of 200 g per 20 liters of water.

Cooking Technology:

- Glue is bred in water.

- Sand is sieved through a metal sieve and combined with cement.

- The resulting mass is poured with the necessary amount of adhesive water.

- Knead the solution using an industrial mixer, the consistency of thick sour cream. When a more fluid material is required, more liquids are added to the finished product and the product is kneaded again.

Application Technique

The technical process for performing improved plaster differs from other types of finishes.

Building foundation preparation

Instructions for the preparation of the building foundation:

- Remove the old coating.

- Brush the dust or use a vacuum cleaner to clean the surface. If there is strong dirt, wash the base with a damp cloth and allow it to dry.

- Degrease the surface to remove oil and grease stains.

- Examine the building base for mold and mildew. If an aggressive biological environment is found, treat the area with an antiseptic solution.

- Knock the surface with a hammer and if any fragments fall off, expand and deepen the defects.

- Apply one coat of primer, wait for the composition to dry and re-treat.

Solution mixing

If the master uses a dry mixture for plastering, then the material needs to be prepared:

- Put the material in a clean bucket and add water - the proportions are indicated on the package.

- Knead the solution using an industrial mixer.

- Leave the material for 5-10 minutes to insist, stir again and immediately use as directed.

Material application

Technological sequence of performing improved plaster:

- Spray A liquid solution is used for this layer, but the consistency is made such that the material does not drain from the walls. Plastering a bucket or trowel throw the composition on a building foundation. The solution is sprayed so as to cover the entire surface and fill in the defects. The thickness of the material is 5 mm. Such a layer is not leveled. The hilly surface improves the adhesion of the surface to the material.

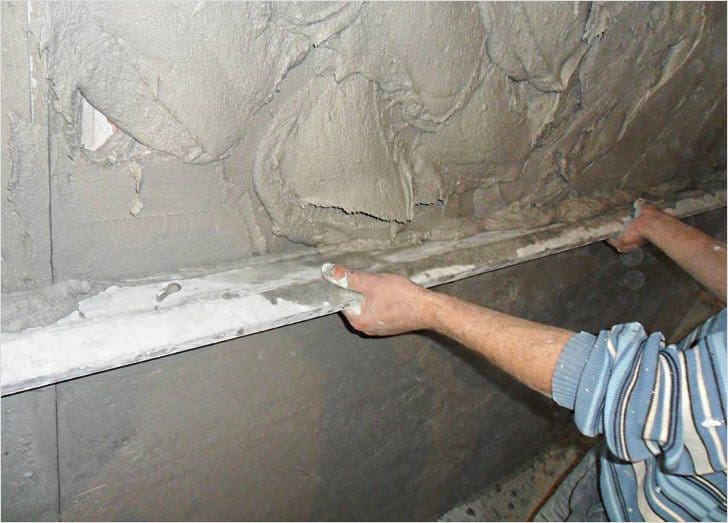

- Priming. A thick sour cream consistency solution is used for this layer. The thickness of the product is 8 mm. The material is applied to the base and leveled using the rule, as in the photo below.

- Finishing This layer is called a lining. The solution is applied after solidification of the soil, the surface is pre-moistened with water. Layer thickness - 2 mm. After surface treatment and setting, the agent is leveled with a trowel.

Grout

This is the final step in performing advanced plastering. Grouting is done only after final solidification of the solution. For this, an industrial grater is used. The tool is tightly pressed to the surface and processed in a circular motion. Then move the grater horizontally and vertically. After that, the surface is swept, primed and decorated.

Tolerances

When performing improved plastering, deviations from the norm are allowed:

- vertical deviations - not more than 2 mm per 1 m2 of surface;

- errors on the perimeter of the base - not more than 10;

- horizontal deviations - not more than 2 mm per 1 m2 of surface;

- permissible errors for slopes - 2 mm per 1 m2 and not more than 4 perimeter of the base.

Quality control

Finishing quality control is carried out in several stages:

- A visual inspection is carried out for defects and irregularities. If gaps or depressions are found, imperfections are sealed with a solution. If unevenness is detected, the surface is ground.

- The rule, 2 m long, is held upright and pressed to the surface. The device is carried out around the perimeter. If irregularities are detected, the defects are corrected.

- The patterns make measurements of curved surfaces.

- The level checks the door and window openings for distortions.

- An industrial corner checks the quality of the corners. The device is pressed tightly against the surface and lead from the bottom up.

In the video in this article, the wizard demonstrates the technique of performing improved plastering.

Improved plaster is a finishing method that prepares the surface for decoration. The appearance of the finish and the duration of the operational period depend on the quality of the implementation of this stage.