How to plaster walls from aerated concrete - requirements, nuances, secrets

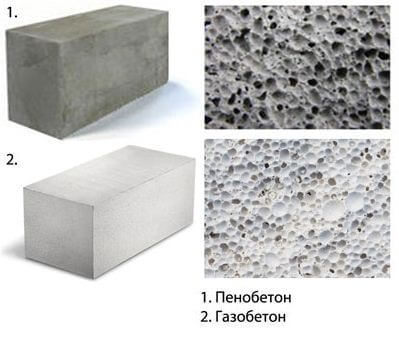

Aerated concrete is a modern building material, reminiscent of foam concrete in structure, but differs by air bubbles located inside. The hollow structure of aerated concrete absorbs moisture well, which requires external finishing of the material. The better to plaster walls of aerated concrete, is considered in the proposed article.

The content of the article

Plaster requirements for aerated concrete

For the manufacture of the material used:

- silica sand is the basis of the mixture;

- lime;

- cement;

- water;

- aluminum powder is added during the manufacturing process of the material. It acts as the main blowing agent and gives the material a specific structure.

Tip: When purchasing aerated concrete, it must be borne in mind that the pores of the blocks, unlike foam concrete, are open. This determines the features of its application and finish.

Comparative characteristics of foam concrete and aerated concrete are presented in the table:

| Foam concrete | Aerated concrete |

| In its structure, air bubbles do not connect with each other, which increases the resistance of the material to getting wet. | Air bubbles are interconnected, which allows moisture to move freely around them. |

| Good qualities of frost resistance and thermal conductivity. | It gives off heat and freezes from frost. |

| The inner layer of the plaster layer should be twice as thick as the outer | Walls should be plastered indoors, and then on the facade of the building. |

| To improve the adhesion of the wall, it is necessary to clean it, then carefully sand it to remove the upper water-repellent layer. Due to poor moisture absorption, to increase adhesion, a solution is sprayed, and then the main layer is applied. | Adhesion rates are higher |

When plastering the outer surfaces of aerated concrete, it is necessary to take into account its high hygroscopicity.

This requires the use of non-standard plasters, which over time will not lead to:

- Cracking of the internal and external surfaces of the building, as in the photo.

- The manifestation of masonry traces after fog or rain, which worsens the visual parameters of the walls.

- Change in technical specifications.

- Increase indoor humidity.

- The appearance at the corners of the mold rooms.

For exterior surfaces, special facade plasters. A particular danger to aerated concrete slabs is temperature extremes and large frosts.

During operation, a certain amount of liquid begins to accumulate inside the structures, which will expand during freezing and can greatly damage the structures of the structure. Aerated concrete substrates can only be plastered with mixtures that have good water-repellent properties that do not impede evaporation from moisture walls.

For exterior finish of aerated concrete, plaster should have:

- Good adhesion parameters.

- High compressive strength.

- Frost resistance.

Tip: Owners of buildings made of aerated concrete blocks should be aware that the external decoration of the walls is carried out only after all internal facing works. Otherwise, when carrying out “wet” interior decorating, the walls will absorb a significant amount of moisture, which will subsequently evaporate.

If the external facade will be finished before applying the internal plaster, during its intensive evaporation, a peeling of the external plaster layer from the surface of the aerated concrete will appear. After the interior decoration of the premises, it is possible to clad the walls of the house outside with special compounds having the highest vapor permeability.

Tip: You can not plaster facades using standard cement-sand mixtures because of their insufficiently high vapor permeability properties.

Stucco plaster

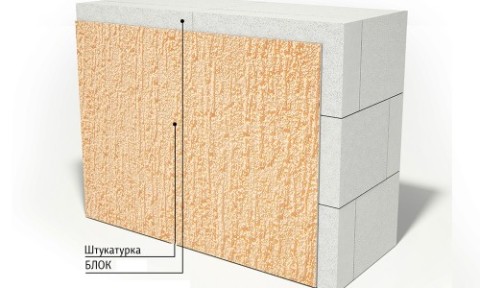

For wall decoration, vapor-permeable aerated concrete plaster is used, which allows water vapor to pass well, does not get wet, with good adhesion to the surface of the blocks and high frost resistance.

| Type of plaster | Material Features |

Material disadvantages:

| |

Disadvantages: a small selection of colors, loss of appearance, due to the subsidence of dust and dirt on the surfaces of the walls. | |

Disadvantage: high cost, but over time, it is likely to pay off. In this case, it is appropriate to recall that the avaricious pays twice. | |

Advantages of the composition:

Disadvantages of gypsum plaster:

|

Lime-cement plaster

All the necessary properties are inherent in light thin-layer plasters, specially created for surface finishing from aerated concrete. An example of such a plaster can be - Baumit HandPutz for wall decoration with your own hands, produced in bags weighing 25 kilograms.

Its main physical properties are given in the table:

| Name of indicator | Its meaning |

| Granularity, mm | 1 |

| The tensile strength of the material in bending, tensile, N / mm2 | ≥0,5 |

| The compressive strength of the composition, N / mm² | ≥3,5 |

| The coefficient of resistance to vapor permeation μ, | 15 |

| Heat conductivity coefficient λ, W / mK | 0,8 |

| The density of the mixture in dry form, kg / m³ | 1600 |

| Fluid flow rate, liter / bag | 6-7 |

| Mixture consumption (with a layer thickness of 1 cm), kg / m² | 15 |

| Minimum layer of plaster, mm | 5 |

| The maximum layer of plaster, mm | 20 |

Tip: Before plastering aerated concrete with this plaster, you must first spray the surface of the wall with Baumit Vorspritze mortar.

Material selection

To choose which plaster is better to plaster walls from aerated concrete, you need to purchase a plaster composition that satisfies the characteristics:

- good vapor permeability;

- optimal volume of liquid for mixing the mixture: per kilogram of the mixture - not more than 0.2 liters of water;

- certain values of the minimum and maximum thickness of the plaster;

- good adhesion with a base of at least 0.5 MPa;

- resistance to freezing temperatures;

- high resistance to cracking;

- the longer the pot life of the mixture, the larger it is, the easier it is to work with the solution, especially for beginners.

The order of plastering walls of aerated concrete

Before starting work, it is better to get acquainted with the video in this article.

Tip: Building blocks of cellular concrete are quite even with almost imperceptible seams. It is not necessary to use for leveling surfaces of stucco mortars. It is enough to apply only a thin layer of the mixture.

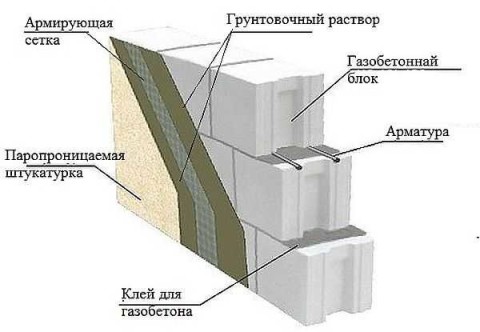

The instruction for plastering walls offers the following procedure:

- Primer surface. Composition specially designed for aerated concrete, the surface of which actively absorbs moisture, is applied with a brush or roller.

- A reinforcing mesh is mounted, which is attached to the surface with self-tapping screws (seeHow to fix a stucco mesh to a wall).

- The walls are finished with a thin layer of plaster.

Properly selected plaster mixes for aerated concrete blocks allow you to make your house not only beautiful, but also warm, preserving all its positive characteristics for a long time.