Choose what to plaster gypsum block

Plaster, as such, involves leveling the surface, but note right away that not all walls need it. For example, enclosing structures mounted from gypsum and foam concrete blocks with lock joints at the ends are smooth enough so that they do not require a thick layer of plaster.

Therefore, to the question: “Do I need to plaster the gypsum block?”, We answer this way. It is not necessary to plaster - it is enough to putty to hide seams. But what putties are used in this case, as well as how to plaster the walls of the house from concrete blocks - we will talk about this later.

The content of the article

Why putty

Reasoning on the topic: "How to plaster a wall of blocks", Without specifying at the same time what kind of them was used for masonry walls, it is impossible. The fact is that the basis of concrete and gypsum blocks is completely different materials - respectively, and there must be a different approach to their plastering.

Note! When applying a plaster composition to the surface, you need to keep in mind the basic rule: the bottom layer should always be more durable than its coating. For this reason, the answer to the question: “How to plaster a gypsum block?”, You can definitely. Putty the surface of such walls, as in the case of drywall (seeHow to putty drywall quality), you need only gypsum, or lime-gypsum compounds!

Features of gypsum walls

Today in construction, several types of structural material from gypsum are used. These are not only blocks whose dimensions are similar to those of ash and cellular concrete blocks (390 * 190 * 190 mm), but also slabs of a rather large format (670 * 500 * 100 mm), which you see in the photo below. Both blocks and plates have a protrusion (ridge) on one side and a groove on the other.

- In order to carry out the layout of the room, it is difficult to even come up with more convenient material. The reason for this is not only the low cost of products, but also the simplicity of their installation, which allows you to do the work yourself even to a person who is far from construction.

- Mount gypsum boards and blocks with a groove up - respectively, the comb is inserted into the groove of the underlying block. If this is the first row, then the protrusion is sawn off and cleaned with a peeling plane. The base under it is always smooth, concrete. The position of each plate is verified according to the level, so that such a wall cannot be uneven in principle.

- Everyone knows that gypsum is very sensitive to high humidity. And, nevertheless, gypsum boards are also used for the erection of the outer walls of low-rise buildings. How is this possible? The fact is that to give the products moisture resistance, they are treated with a hydrophobic composition at the factory.

- At the same time, white plates acquire a characteristic greenish tint, which can be hidden only under a layer of putty. In principle, when finishing the room, then when gluing wallpaper with a thick pattern and deep relief, neither the seams nor the color of the gypsum wall will appear.

- In this case, you can simply repair the joints, grind and primer the entire surface of the walls (seeWhy do we need a primer: technological nuances of finishing work) - and you can glue the rolled material. However, if these are thin light wallpapers, then hiding the seams under them and the green shade of the base will be problematic. That is why it has to be puttied over the entire surface.

- Note that we are talking only about the interior decoration. Outside, it is recommended to close the plaster walls with heat-insulating plates, on which plastering is carried out. Since in this case the plaster does not come into contact with the gypsum base, cement-based formulations are used - or even choose one of the finishing options according to the system of ventilated facades.

- Manufacturers dry gypsum plasters and putties, usually offer mixtures of mixtures specifically designed for plaster walls. From the options for drywall, they are distinguished by a slightly coarser dispersion - 0.14 mm versus 0.08 mm.

Therefore, when buying material, you need to clarify its purpose. Similar information contains instructions on the package with the mixture. Well, how to properly perform plastering work - you will learn about this by becoming acquainted with the video in this article.

Masonry from concrete blocks: what is the difference

Unlike gypsum surfaces, walls erected from concrete blocks can be plastered with any composition. Typically, cement and lime-cement compositions are used from the facade and in damp rooms, and in gypsum and gypsum-polymer compositions, in dry rooms.

- But some types of blocks suggest a slightly different scenario. Depending on the composition and manufacturing technology, wall products have different operational characteristics. Accordingly, different requirements are imposed on their plastering. Let us say briefly - what, in fact, is this difference.

All small-format wall blocks used today in low-rise construction are made of lightweight concrete.

Moreover, they can be divided into three categories:

- Polystyrene concrete blocks. They are filled with polystyrene granules.

- Ash concrete blocks. These wall products are produced without the autoclave method, and blast furnace slag or expanded clay is present in their composition.

- Mesh blocks. This includes options manufactured by the autoclave method: foam blocks, gas and gas silicate blocks, which, although they are manufactured using different technologies, but the result is approximately the same: the products are porous and very light.

From this list, only in some types of foam blocks may not be part of the cement. As a binder, they use lime and finely ground blast furnace slag.

Use them only for the laying of curtain walls. Due to the lack of cement, the strength of such products is quite low - respectively, and a lower price, which attracts buyers.

- But for partitions of great strength and is not required. The only thing to remember is that since there is no cement in the base, then it cannot be plastered with cement mortars. To finish the masonry from cementless blocks, the same compositions are used as for gypsum blocks - that is, lime-gypsum.

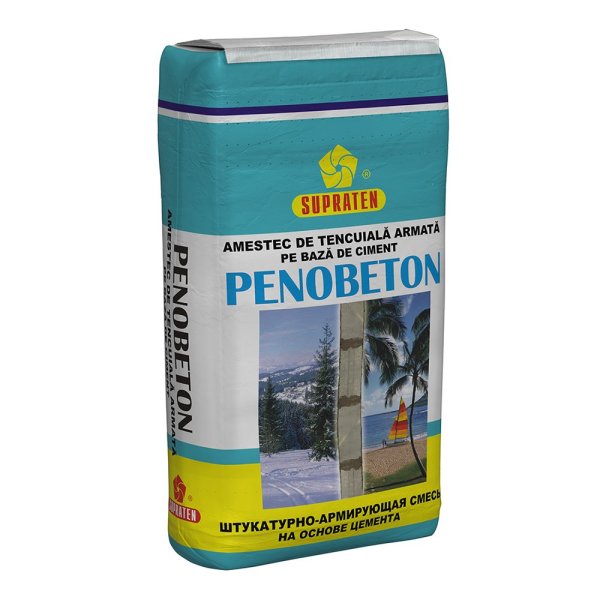

- As for the standard foam blocks made using cement, and all other types of cellular concrete blocks, specially designed mixes should be used for their plastering. In addition to the fact that they are always based on cement (mainly white), they are also reinforced with cellulose or polymer fiber.

Reinforcement provides maximum adhesion of the plaster to the base, and strengthens it, preventing the appearance of cracks. Autoclaveless blocks with granular filler are more unpretentious in this regard, therefore, cinder block plastering, or masonry from expanded clay concrete blocks, can be performed with the most ordinary cement-sand mortar, or with purchased mixtures on a cement or gypsum basis.

Good afternoon ! If you plaster the cps according to your option .... The walls are not even, the deviation is up to 15 mm ... Plasterboard cps on beacons, such a layer will withstand glue with a grid ...?