Plastering machine: as used by masters

Plastering machines are special equipment designed to apply plaster mortar to any surface when repairing a room or building facade. The use of aggregates can significantly increase the performance of work and improve the quality of applying the composition. The article will tell you how to use plaster machines for decorating your walls with your own hands.

The content of the article

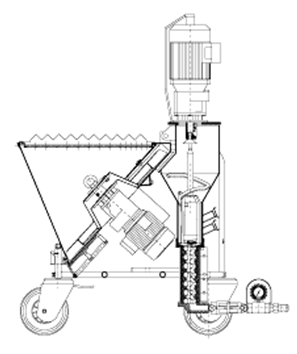

The principle of operation and arrangement of machines

Plastering machines are devices designed to facilitate the execution of construction work, in which:

- Water is poured.

- Cement or dry gypsum mixture is filled up.

Next car:

- Kneads the composition, in the required proportions.

- It supplies under pressure, through a blower hose, plaster to the surface.

The task of man is to lead the process:

- Hold the hose.

- Make sure that the solution lies on the wall in approximately equal portions.

Thus, horizontally, by drawing line after line, the entire wall is filled. In this case, the movement of the plaster hose resembles the movement of a seismograph or cardiological device - from side to side.

Tip: When connecting the machine to the mains, certain rules must be observed - the device is not safe.

The unit is connected to a network with a voltage of 220V and consists of:

- An engine with a power of up to 1 kW, suitable for applying facade plaster.

- A tank or expansion tank with a volume of approximately 200 liters.

- Dosing hose or spray gun.

- A pneumatic blower that delivers air under pressure that causes the solution to fly out of the hose.

Features of plastering

The stucco machine is used in compliance with several rules, which include:

- The presence of protective suits and goggles during the work, which will allow to avoid human contact with finely divided dry mixtures, which are used when laying a wet facade.

- Do not point the machine hose at a person or stand in front of the machine nozzle.

- The device calculates the number of ingredients on its own. In some types, you can connect the equipment to a centralized water supply, for example, to a tap in the apartment.

- No dyes, additives or mixtures used for manual finishing can be added to the machine: only a special machine gypsum composition is used (seeMachine plaster: how to do it right).

- In the hopper of the unit there is always a kneading of one consistency, without any lumps.

- Water can be poured into the compartment immediately, and the mixture must be poured from the bag through a grill mounted on top of the machine.

- If necessary, the worker adjusts the density of the solution.

- After turning on the unit with a screw or pneumatic actuator, the finished solution is fed into the sleeve.

Tip: The principle of operation of all trowels in manufacturers is approximately the same. However, the instructions for a particular installation should always be studied in detail. This will ensure correct and continuous operation of the equipment.

- Through a sprayer, nozzle or nozzle, under pressure, the mixture is fed to the treated surface, which can be:

- wall (seeHow is mechanized wall plastering done?);

- ceiling;

- floor.

Tip: When applying plaster, the nozzle should only be held perpendicular to the surface.

- When you pull the trigger, the channel opens, and the mixture is thrown with a uniform stream onto the wall.

- For safety reasons, if the unit is turned on, you cannot:

- clean clogged channels;

- add additives to the mixture;

- disassemble the unit;

- carry out any repair work on it.

- Before work, it is necessary to take into account the voltage of the equipment, especially when using cement plaster for outdoor work.

- The air temperature must be higher (+ 5 ° С) in order to ensure high-quality application of the solution.

- The finished composition is applied already in a perfectly mixed composition, in the right proportions and high quality. In this mixture:

- It has excellent physical and mechanical properties:

- has a good density;

- lays firmly on the wall with minimal porosity.

Plastering technology

Before carrying out work, the walls must be cleaned of dust and all excess elements, removed:

- Box.

- Nails

- Holes.

After that, you can start decorating the walls.

For this:

- The surface is primed with a suitable composition, taking into account the humidity in the room.(cm.Primer walls and all for that matter) The primer layer will allow:

- reduce absorption of the treated surface of moisture and solution;

- will protect the wall from fungi;

- will create high adhesion of the mixture to the surface.

- Lighthouses are applied to the walls. These elements can be left after the process of grouting the plaster layer or removed by closing up the formed gaps.

Tip: The thickness of the beacons should be determined by the thickness of the plaster layer, and for proper installation of parts, it is necessary to use a laser equalizer, usually up to two meters in length, and a water level.

- A mixture is poured into the hopper of the machine.

- Water is added. Its volume is determined according to the instructions for a particular machine, based on one bag of dry mix.

- The valve of the supply hose opens. In this case, the nozzle should be located from the wall at a distance of 30 centimeters.

The solution is applied to the wall from its upper left corner, moving the nozzle from bottom to top, as in the photo.

The slower the builder’s hand moves, the thicker the layer of plaster will lie on the wall:

- One strip is applied up to 70 centimeters wide, after which the nozzle moves to the next line below, capturing the previous line by 10 centimeters, thus moving along the entire wall.

- In parallel, the second worker rules even out the applied plaster, removing the excess mixture from the rule.

- In places where there is a lack of mixture, it is necessary to add plaster from the sleeve of the machine and again, rule the finishing area.

- Excess composition or minor defects near the ceiling or baseboard can be fixed separately with a spatula: add mixture or remove excess.

Tip: Do not leave the mixture in the hose idle for more than 15 minutes, and use the mixture in the hopper for more than 30 minutes. This will lead to loss of quality and malfunction of the unit, due to the beginning of the solidification of the solution.

- After applying the mixture to all walls, the machine turns off, carefully disassembled and thoroughly washed in accordance with the instructions.

The price of work with machine plastering is much lower, which is associated with a fairly accurate calculation of materials: the consistency of the working mixture is selected correctly, which saves resource consumption, and the speed and accuracy of applying the mortar allow avoiding its losses during unforeseen hardening and spraying.

Also:

- A homemade stucco machine allows a person to perform a small amount of work in a short time. And how to make the simplest device, the video prompts in this article.

- After grouting and polishing, such a plaster can be applied with paint or wallpaper.

- Using a plaster machine, you can apply:

- gypsum mixture for finishing walls in residential premises;

- cement-lime mixture in garages, basements, technical buildings, sheds, pools.

Advantages and disadvantages of using machines

The advantages of a machine-based plaster application method:

- Quick drying of the mixture, its good quality, uniformity of the composition during kneading, minimal consumption.

- Speed of work - ideal walls in a short time.

- Good smoothness of the walls.

- After acquiring a typewriter, you can start your own construction business.

- Using the device, you can screed floors, make bulk floors, plaster ceilings, apply plaster with cement-lime mixtures around the house for painting or laying tiles.

- The mixture after machine application gives the walls better thermal insulation, due to the density of the solution.

The disadvantages of the machine method:

- The big weight of the device.

- The high cost of the car.

- The published noise of the device.

Using a machine for applying plaster on the wall facilitates the work of the builder, he can only quickly manage the rule in order to level the finished fresh mortar on the walls. The problems associated with finding a container for mixing the composition, mixer, with the acquisition of spatulas, and most importantly - saving labor and energy of the worker, are disappearing.