How to insulate the walls of the house outside: the choice of material, practice, some secrets

How to insulate the walls of the house from the outside must be decided before starting work. After all, there are several materials and they are not only different in composition, but also in the fastening system. And the better to insulate the walls of the house outside, we will consider below.

The content of the article

The advantages of external insulation

External insulation performs an important protective function and has several advantages:

- The most important plus of external thermal insulation - lack of freezing. When the house is insulated from the inside, the walls are not protected from freezing and hypothermia. In cold walls, heat loss occurs faster.

- Increases the strength of structures made by frame technology. With internal insulation in structures of this type, there is a constant accumulation of condensate, which contributes to their gradual destruction.

- There is no additional pressure on the bearing walls and the foundation.

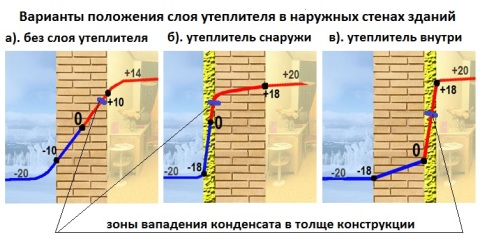

- The dew point is an accumulation of steam. It is located in a layer of external insulation, which eliminates condensation. The heater, having vapor-permeable properties, lets condensate out. With internal insulation in the wall, from the side of the room, moisture accumulates, creating a favorable environment for the appearance of fungi, mold and freezing of walls.

- The walls are protected from the cold, and the heat is held inside them for a long time.. His losses are minimal.

- External thermal insulation has such an important property as high-quality sound insulation.. The aspect insignificant for suburban real estate is important when warming houses and buildings located on noisy city streets.

Types of insulation

In the manufacture of plates for thermal insulation, various materials with thermal insulation properties are used. As a heat-insulating material, foam boards and mineral wool are most in demand. Qualitative characteristics of the plate should be the main selection criterion when buying a heater.

Mineral wool

If you think the better to insulate the front wall, then you should immediately pay attention to mineral wool (seeHow is insulation of walls outside with mineral wool) These are plates made of various fibers. The thickness of the material is usually 5-10 cm.

Mineral wool mats are produced for large-area work surfaces. Simplicity of installation and a number of advantages ensure high demand for insulation.

Mineral wool does not burn, has moisture resistance, low heat conductivity, vapor permeability, soundproofing properties, and is not subject to external influences.

Depending on the material on the basis of which the insulation plate is created, its types are classified.

Types of mineral wool:

Minvata stone | The material for the manufacture of this type of mineral wool is molten rocks: basalt, clay or limestone. Stone wool does not burn, does not rot, withstands large temperature extremes. Its porous surface has excellent “breathing” properties. A plate made of natural material is a natural, environmentally friendly insulation that does not emit toxins. |

Minvata slag | It is made from metallurgical waste - molten slag. The finest fibers at the base of the material give it a resemblance to felt. It has high heat-insulating properties, does not burn, and passes vapor condensates well. |

Fiberglass mineral wool | The material made on the basis of glass chips is resistant to high temperatures. Like other types of mineral wool, it does not burn, does not absorb moisture, is not susceptible to damage, has “breathing” properties and is easy to assemble. Glass wool contains the finest glass dust, so measures must be taken precautions to prevent its contact with the skin and mucous membranes. |

Polystyrene foam plate

If you think about how to insulate aerated concrete walls, then this material is completely suitable:

- It consists of small spherical or cellular granules with hydrophobic properties.

- In the manufacture of foam, the high temperature effect on the granules contributes to the formation of a single structure.

- The lowest price in the niche of thermal insulation materials and easy installation during the insulation process provided expanded polystyrene immense popularity (see.Do-it-yourself insulation of the walls from the outside with polystyrene foam).

- Plates are made with a thickness of 5 to 15 cm. And you can carry out insulation without selecting a lot of usable area.

Features:

- A foam plate almost entirely consists of air enclosed in micropores of granules. This is due to the light weight of the material.

- There are 2 types of foam: expanded, from larger round granules, and extruded, from small cells. For external insulation of the walls of the house, the first option is preferable. Extruded polystyrene foam has a finer structure and is used mainly for the insulation of non-residential premises, residential buildings.

- When erecting a heat-insulating structure from expanded polystyrene foam, it is necessary to apply additional cladding to the insulated surface or plastering (Styrofoam can release toxins when exposed to high temperatures).

Technologies for outdoor insulation

Before you insulate the walls of the house, you need to think about how to do this. After all, material fastening and subsequent finishing are of great importance.

If this is the entrance wall, then it’s stupid to talk about mineral wool. After all, it will also have to be faced. But the foam is suitable, it is enough to plaster it.

The following is a brief installation guide for the most commonly used insulation materials. This will help you choose the option you need.

External thermal insulation is of 2 types:

- Bonded thermal insulation;

- Hinged ventilated facade.

The first, the method of monolithic fastening of heat-insulating material is most in demand. This type of insulation is easy to do with your own hands, while the sophisticated technology of the curtain wall requires a qualified approach and high costs.

Benefits of Monolithic Bonding

The method of monolithically bonded insulation requires a plus air temperature above 5 ° C. Therefore, work on insulation in this way are seasonal in nature. A popular method of thermal insulation in Western countries is becoming popular in Russia.

- Energy Efficiency: A significant reduction in heat loss through monolithic walls reduces heating costs.

- A monolithic heat-insulating shield reliably protects the walls from cold, wind, moisture. A single enclosing structure eliminates the appearance of “cold bridges”. The simplicity of the design allows, if necessary, to easily dismantle the layers of thermal insulation.

- Light weight of insulation materials does not exert additional pressure on the foundation.

- Mounted bonded insulation is possible on surfaces of any material (blocks, bricks, panels, frame).

- The use of non-combustible types of insulation ensures the durability of the structure.

For the effectiveness of external insulation by bonded thermal insulation, compliance with the technology is necessary. The quality of the insulation material also matters. The most commonly used polystyrene, mineral wool or glass wool. When choosing a foam, its flammability must be taken into account, although manufacturers began to produce non-combustible types of expanded polystyrene.

Bonded thermal insulation with polystyrene boards

This installation method depends on the material used.

- When it comes to mineral wool, aluminum guide rails and additional hardware are required.

- Expanded polystyrene is fastened with special glue and dowels. Plates are glued to the wall, and dowels provide additional fixation.

Dowels must withstand the load of the entire structure and strong gusts of wind.

Attention: Special expansion bolt shields for installation of thermal insulation have a large diameter of a hat, 5 cm and more. For fastening polystyrene foam plates, 2 types of dowels are used: ordinary (5 cm) and elongated (9 cm).

For external thermal insulation, it is necessary to choose polystyrene foam with fire-resistant characteristics.

External bonded thermal insulation technique:

- Special glue is applied to the surface in a continuous layer, the size of one foam board.

- Foam is pressed against the wall with adhesive and is held for better adhesion for a short period of time.

- Excess glue from under the foam plate is distributed under the neighboring ones. This contributes to additional bonding of the joints.

- The joints of the plates are filled with polyurethane foam or small pieces of polyurethane foam.

- Corner joints of insulation canvases are fixed with dowels. The joints on the surface of the plates, together with the dowel caps, are covered with a compound of mastic. A single monolithic layer of heat-insulating material should be obtained.

- The next step is the installation of a reinforcing mesh, which is bonded to the surface of the plates with glue. To create a continuous reinforced area, overlapping mesh is used.

- After complete drying, the resulting insulating layer is leveled for further decorative cladding.

- Application of decorative plaster.

- The final stage is staining with paint intended for external use. Paint and plaster must be resistant to environmental influences.

External thermal insulation with polyurethane foam

Thermal insulation with polyurethane foam (PUF) involves spraying the composition onto the wall. The polymer layer hardening provides reliable thermal insulation and a monolithic smooth surface. An insulating compound is prepared immediately before work.

A promising modern method of insulation has several advantages:

- High adhesive properties, instant strong bond with any kind of surface;

- Seamless technology increases the thermal inertia of the walls, providing additional strength;

- Polyurethane foam (seeInsulate the wall with polyurethane from the outside - how to make the right design), applied with a layer of 5 mm, is not inferior in thermal insulation properties to a slab of mineral wool 15 cm thick or foam 10 cm;

- The plasticity of the polymer material ensures rapid application and the absence of tears, seams;

- High moisture repellent and soundproof properties;

- The tightness of the applied layer does not require additional protection with a vapor barrier and windproof material;

- The light weight of the applied polymer does not exert a load on the bearing walls and the foundation;

- Quick application;

- The polymer composition does not emit toxic substances.

Attention: If the question is how to insulate the wall before wallpapering, then this material comes first.

Working with polyurethane foam provides for accurate spraying and protection of other surfaces with a covering material. When frozen, it is almost impossible to remove.

The prepared mixture is applied using special equipment in which 2 polymer compositions are mixed under high temperature exposure. The mass brought to the state of foam through a special sleeve is sprayed onto the insulated wall.

This thermal insulation includes the following steps:

- Preparatory stage. The surface of the wall must be cleaned of dirt, dust, previous coatings. Any foreign particles on the wall will reduce the bond coefficient.

- Spraying polymer composition. The plasticity of the polymer allows you to align the walls, filling the hollows. The thickness of the polymer layer depends on the feed power. With the spray gun you can adjust it.

- Laying the reinforcing layer (fiberglass mesh is great). It is recommended to apply a layer of screed more than 6 cm thick.

- Decorative cladding with finishing materials (paint, siding, block house).

Warm plaster for external thermal insulation

This type of plaster differs from ordinary cement mortar in its composition: in addition to cement, it includes particles of insulating filler: granular polystyrene foam, crushed volcanic glass, a mixture of sawdust with paper or foamed vermiculite.

- The porous structure of the plaster gives it “breathable” properties. For external insulation of facades, plaster with polystyrene granules or expanded clay crumb is suitable. The sawdust base of the plaster is suitable only for interior use.

- The composition should have high thermal conductivity, breathability, good vapor condensate and repel moisture.

- Warm plaster has a plastic texture and is easy to apply without requiring additional smoothing. Reinforcing mesh can not be used. It is applied, like regular plaster. Sanding or putty will ensure a perfectly even surface.

- Plaster with thermal insulation properties is well bonded with any wall material, has a "breathing" surface.

Warm plaster meets the high requirements for heat insulating materials.

Stucco properties:

- Low thermal conductivity;

- Vapor permeable and hydrophobic properties;

- Breathability;

- Durability;

- Resistance to external influences and decomposition;

- Incombustibility;

- Lack of toxic substances.

Where to use warm plaster:

- Plaster is used for external cladding, window slopes are insulated with it, glossy joints, cracks.

- Easy application does not require additional adjustment. Properties such as resistance to external influences, strong bonding with the base, allow it to be used on any surface.

- The mixture is applied in the same way as regular plaster. After complete drying, the surface can be sanded.

External thermal insulation of wooden houses

In suburban construction, wood is often used as a material for the construction of walls. This is explained by naturalness and safety from an environmental point of view.

Attention: External insulation of walls made of wood is possible using technologies that provide ventilation. To protect the wooden walls from decay, a ventilation gap is mandatory.

As insulation for wooden structures, expanded polystyrene or mineral wool is most preferred. The choice is due to the excellent thermal insulation properties of the material, high vapor permeability, fire resistance, moisture removal ability and ease of installation.

The heat-insulating construction of wooden walls is a multi-layer “pie”:

- Interior decoration;

- The bearing wall is made of wood;

- Vapor barrier film;

- Insulation plate (mineral wool, polystyrene foam);

- Windproof material;

- Ventilating clearance;

- External cladding with decorative material.

The process of warming wooden walls:

- Preparation of a wooden surface. At this stage, the wooden wall is treated with a special antiseptic solution and fire retardant treatment. Slots are filled with foam or caulked. For caulking, you can use tow, felt or a special sealant for wood.

- Fixing on the wall with strips, overlap, vapor barrier material. Joints are sealed with sealing tape.

- Installation of the crate. The crate is made from prepared and treated with antiseptic bars. The thickness of the insulation plate should be 20% of the width of the guide bar. In other words, the crate should protrude above the insulation layer. The width between the slabs aligns the distance between the guide rails.

- The crate is filled with plates. Additional plate fasteners are carried out using anchors.

- Installation of windproof material.

- Exterior finish (block house, siding, decorative brick).

What to insulate the walls of the house from the outside, you now figure it out yourself. Be sure not to miss the size of the insulation, a layer of finishing material will still need to be added to it. After all, he also takes a place. After watching the video in this article and the photo, you can make the right choice.