Insulation of the wall in the apartment from the inside: the right choice of insulation is the key to success

Wall insulation inside the apartment is generally not practiced. But sometimes without this type of work just can not do.

Today we will consider what is the insulation of the interior walls of the apartment, and you can make the choice of the right material. Also, you should know that internal insulation is not limited to wall decoration, it is a set of works and only by completing them you can get the desired result.

The content of the article

When can I insulate the walls inside the apartment

Insulating the walls in the apartment from the inside is a big risk. Therefore, builders are always trying to find other ways to solve this problem.

There are only three reasoned reasons for which such work is possible:

- If the building has historical value, or if it is about the front side of the facade, and also, if it goes to the main highways of the city, it is forbidden by law to change anything on such facades. Accordingly, insulation is possible only from the inside.

- If behind a wall that needs to be insulated, a joint with a neighboring house is found (expansion joint). This situation leaves builders with no choice - such a wall should also be insulated inside the house.

- If the insulated wall exits the elevator shaft or other technical rooms (unheated) from the outside, then insulation can only be done from the side of the apartment.

- Also an acceptable case for internal insulation is the possibility to produce it inherent in the design documentation of the construction. Today this opportunity is provided for in the construction of houses using frame technology (seeWhat insulation is best for the walls of a frame house).

Attention: If the insulation of such a house is not enough, then it is enhanced by using an additional insulator layer (it is correct to use an insulator of the same brand that was used during construction). The owners of wooden houses must adhere to the materials (from the inside they must be insulated with wood, and not with other types of materials).

In any other cases, you should not consider this option of wall insulation. It is necessary to carry out all the necessary research, raise all the documentation and get comprehensive advice from specialists to make sure that this type of insulation is inevitable. If there is such an opportunity - it is better to insulate the walls outside. Regardless of the fact that the exterior may change.

The insulation of the walls from the inside in the apartment with your own hands should begin, only after a thorough study of the issue. Indeed, in this case, the thermal insulation coefficient is significantly reduced.

The specifics of the insulation procedure

This type of insulation has one serious feature that must be remembered: the insulated wall becomes colder than before the insulation. Where moisture condenses from the warm air of the apartment, dampness forms, which is discharged to the inner side of the wall.

This will lead to the destruction of the wall, the finish layer will begin to deform, and the insulation will begin to lose its thermal insulation properties.

Attention: Thus, it is possible that the wall will cease to be warm, which will also add increased humidity.Typically, such a sad prediction is most exposed to brick walls.

- This specificity of internal insulation can be avoided if, when choosing a heater, pay attention to the presence of such characteristics as: moisture absorption and minimal vapor permeability. During installation, it is necessary to carefully ensure that there are no, even microscopic, joints.

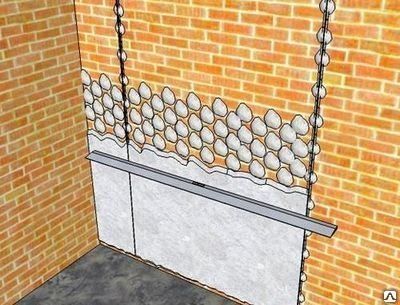

- If the area of the room allows, then the ideal solution would be the construction of a second wall around the perimeter of the room. In this case, all problems with thermal insulation will be excluded. The second wall can be tightly joined with the main one, or create a gap for the insulation. But this solution is far from suitable for everyone.

What you need to know when working

Warming and sound insulation of walls in the apartment is done at the same time.

Professionals advise to pay attention to the following points:

- High-quality vapor barrier can save the situation if it is connected with sealing at the seams.

- The thermal insulation itself should have a low vapor permeability index. If on the wall this figure is higher, and on the insulating material less, then the steam will go outside.

- To achieve full docking of the insulation with the wall, experienced craftsmen use the beacon method and work with glue comb. The material should absolutely not lag behind the wall.

- Increasing humidity can be avoided by installing additional ventilation. Also use valves on the windows.

- Before installing thermal insulation, it is necessary to treat the wall with an antifungal composition. It is very difficult to get rid of mold and fungus. This trouble is better to prevent even at the preliminary stage of preparation for the main work. After processing, the walls should be dried.

- Much attention should be paid to “cold bridges”. They are located at the joints of the overlap with the wall itself or with other internal walls of the building. You need to walk along this bridge with a heat insulator using vapor barrier. At the stage of finishing, these problematic joints are hidden under the columns or designer boxes.

Attention: Insulating the walls from the inside in the apartment is done after selecting the material. All the characteristics and thickness of the insulation layer are important here. Must be read the instructions before purchase.

Pros and cons of basic materials for internal wall insulation

Internal insulation of the walls of the apartment can be done with several materials. All of them are different in their structure and characteristics.

In general terms, they are divided into two types:

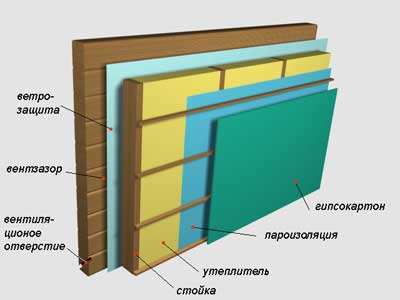

Matte insulation | Here, the insulation is presented in the form of a mat, which has its own dimensions. When laying it, a crate is made in width for this mat. Also, crossbars are sometimes attached, the distance between which should be equal to the length of the mat. Such insulation is made easier. Here are not large sheets that you can always mount with your own hands and without outside help. |

Roll insulation | In this case, the insulation is simply rolled up. You can cut it to the right size and do not worry about additional battens. |

Minvata

The raw materials for the production of the material are glass melt, rock melt or blast furnace slag melt. The structure of the material depends on its type. Its fibrillation can be spatial or corrugated, vertical or horizontal.

The variability of the fibrous structure significantly expands the scope of the material.

The main technological characteristic is:

- Resistance to chemicals and temperatures;

- Excellent heat and sound insulation characteristics;

- She makes the insulation of the walls of the corner apartments from the inside along the seam. After all, this material is elastic, it can fill all the voids.

Minvata is very widely used for warming rooms of any type.Often, builders use this material to work with surfaces such as stoves. They have exceptionally high temperature surfaces, therefore they need serious insulation work.

Caution: Any structures that require fire protection are also insulated with mineral wool. It is not uncommon to use material only for the purpose of sound insulation, as excellent acoustics screens.

- Mineral wool is non-flammable and environmentally friendly, this is a distinctive feature over the foam complex that is often associated with it.

- The material in recent years is very popular, due to the speed and simplicity of its laying in a drywall design and relative cheapness. Neglect of quality and technological characteristics, namely, vapor barrier, leads to negative results.

The main disadvantages of mineral wool:

- Standard mineral wool (which is supplied in rolls) has a minimum coefficient of heat resistance.

- The fibrous nature of the material helps moisture pass to the “dew point”, and then mineral wool absorbs all the moisture into itself. Such a wall will not be particularly dry.

- The vapor permeability of mineral wool is always greater than the walls of a building. Therefore, moisture has the ability to get inside even with particularly careful installation in compliance with all standards. In this case, there is a high probability of drips and fungus.

Polyurethane foam

Ultralight plastic material based on heterochain polymers (or polyurethanes), whose composition up to 90% consists of gas (inert phase). This material is divided into types of hard and elastic.

The composition of the polyethylene foam can be foaming itself and after application, the composition freezes. Such a composition of the material during construction is very popular.

- The material is not amenable to any organic solvent. After solidification, such a mixture can only be removed mechanically.

- Widely used for internal insulation work. Thanks to its excellent thermal insulation, it creates a good barrier against moisture penetration.

But this material also has nuances that need to be taken into account.

- They occur when applying polyurethane foam to the wall. Initially, liquid foam quickly hardens.

- Sometimes you just need a small thickness when warming, and with a smooth outer part, then it must be applied in parts and with the help of formwork.

- Overlappings and frames for such types of work is not necessary to consider. Because the elements of these structures will conduct cold inside. Dampness will increase.

- Hydroprotection and steam protection are installed on a finally formed and solidified layer. Reiki fastens a film from polyethylene. Then it is glued with sealant.

The main disadvantages of polyurethane foam:

- The material is not strong enough. The finish does not hold, as well as the plaster. To finalize the insulated wall, you need to erect a false wall. It is made from drywall. It is attached to the frame.

- This material is not vapor permeable. It does not pass air, therefore condensation is excluded.

Double wall of various materials

A pretty good option for internal insulation is to make a second wall. After all, the air gap insulates by itself.

- It uses a heating element. The heating element becomes a barrier between the outdoor temperature outside and the room. In the period of severe frosts, you can turn on heating, thereby warming the surface of the wall from the inside, and the “dew point” moves to the middle.

- The second wall has a decorative function. It is built from drywall for a fine finish. A decorative brick wall with a half width can also be erected. It is insulated from the side of the opening with the main (insulated wall).

- This option of two walls of different materials is good for heating and does not damage the wall (dampness also does not form). But it is not economical. For winter electricity consumption will have to pay several times more.

Expanded polystyrene, foam

Known material filled with gas, which is obtained from polystyrene or styrene (its copolymers). The material is obtained by filling styrene with gas, then it is dissolved in bulk from polymers.

- This mass is heated with steam. Thus, in the process of heating, styrene granules increase and sinter into a mold.

- Natural gas is used to fill the granules when it comes to classic polystyrene foam. In the fireproof version - filling takes place with carbon dioxide.

Attention: The main is the insulation of the walls of an apartment building outside, for this work it is most optimal.

- The material does not have the qualities that are necessary for work with insulation from the inside. When installing it (if you still decided to work with it), you should seriously handle the joints.

- If you do not have a large layer for applying insulation, then of course it can be applied. There are also quite thin sheets;

- Also, the material is simply cut and fastened;

- Expanded polystyrene is sold in the form of sheets of a certain size, it has a good density. Therefore, it is almost impossible to avoid joints. The sheets must be adjusted tightly to each other, and their ends should be treated with sealant (seeExpanded polystyrene: insulation of walls from the inside in order).

The main disadvantages of polystyrene foam:

- The standard application method for polystyrene foam entails the formation of air bubbles. Condensate is collected in them. Then water will seep into the room, spoil the decor elements and contribute to the growth of mold. This can be avoided by evenly distributing the adhesive throughout the sheet. Due to which a fairly tight grip may form with the insulated wall.

- In order for the solution to hold the material well, before applying it, you need to use a professional roller. The wall needs to be leveled so that this mounting method is possible. It is desirable to level the wall with special mixtures. In their characteristics, increased moisture resistance should be present.

- Anchor type fasteners for polystyrene cannot be used. Their use threatens to form leaking junctions. Reinforcement or plaster on top of polystyrene foam must be reinforced with t-shaped profiles. Profiles are inserted between sheets and strengthened on all sides.

Caution: Using this material in private homes, you risk attracting rodents. They live and reproduce perfectly in it.

New materials for insulation

Progress is constantly going in front and new materials are being invented. We give examples of the last three options for insulation. They appeared not so long ago.

And so the decision about the effectiveness to make you:

| Stucco is warm | Particularly attractive because of its spectacular effect. It is hydroscopic and has good vapor permeability characteristics. However, the thermal insulation characteristics leave much to be desired in comparison with other materials, for example, foamed. |

| Foamed polyethylene | Good heat retention due to foil coating. It is difficult to mount due to the fact that between the foamed polyethylene and the wall, it is necessary to maintain an air gap. The gap must be left under the lining. To make an ideal installation with this material, not many can. |

| Liquid ceramics | If we compare this material with mineral wool, then a layer of only 1 millimeter will be equivalent to 5 centimeters of the second. This is a bubble material, in the bubbles of which is air. Thermal conductivity characteristics range from 0.8 to 0.15. |

The market of building materials is developing so dynamically that every season more and more new materials with excellent characteristics for insulating walls from the inside appear. However, most of these new products have not yet been studied.

Operational characteristics can be studied only after a while. In the meantime, it remains to trust professionals, their own knowledge and experience.

Stages of warming

It is better to do the insulation of the walls of the apartment from the outside, but if this cannot be done, then the technology of work must be fully observed.

- First of all, you need to look at the walls and choose the right insulation.

- Read about it and pay attention to the mounting system. After all, it is different and may not suit you.

- Also read the material specifications and watch the video in this article, where there is a lot of additional information.

- Consult with the one who put it. There are tons of forums for this.

After choosing, you can get to work. All of it takes place in the following sequence:

We clear the plane | You need to dismantle the wallpaper, remove the plaster. With a vacuum cleaner you need to clean the surface. It is worth paying attention to places subject to dampness. There may be a fungus. |

Antifungal treatment | It is necessary to treat the wall with antiseptic agents. Next comes the turn of the primer. |

Drying plane | After the previous stages of preliminary preparation, the wall should dry. You can dry it with a conventional heater. Some use heat guns. This method will help speed up the drying process. |

Plane preparation |

|

Warming process

Each material obliges to withstand certain technologies for its installation. It is important to remember that regardless of the material with which work is being done, after they are finished, you need to let the wall dry again. And only then proceed with the construction of the false wall.

- Of course, a framework would be the best solution. To install plasterboard sheets on it. The gap between them will be up to about 5 centimeters.

- With polystyrene foam, you can simply make plaster or mesh reinforcement. Seals must be treated with a sealant, and fixing should be done by uniformly distributing a thin layer of the solution throughout the sheet. The better this installation is made, the more durable the result.

- It is advisable to carry out activities for the complex insulation of walls inside buildings in the summer season. The temperature outside should be warm, precipitation undesirable, as well as high humidity.

- If mold still appears on the insulated wall, then it must be eliminated, the sooner the better. Usually this involves a whole range of procedures. First, experts check the ventilation system in the room.

- Using a special treatment, fungal and mold foci are removed. Be sure to delete every area that has been damaged.

- After this, the site of former damage is treated with reagents. Putty can only be started by following these steps. In the future, it is necessary to strictly monitor the humidity. It should be within 40%.

If all work is carried out in full compliance with technology, then living in a warmed room will be comfortable and safe. The insulation of the walls of the corner apartment from the inside must be done. After all, mostly builders do not put fillers between the plates and here we must take this seriously.