Facing: warm house with a beautiful exterior

When starting to build a house, you need to immediately think about how the facade will be decorated: cladding, insulation, decoration of architectural elements - after all, some types of work can be performed in parallel with the construction of walls. These include facing facades with brick, ceramic blocks, expanded clay concrete blocks with front decor.

In addition, all of the materials listed have an impressive weight, and require support on the foundation, which should be designed for this load. We will tell you about this technology, as well as present examples of facing the facade of the house with materials mounted on the frame.

The content of the article

Advantages of brick finish

As already mentioned, face masonry is performed in the process of building a house. For this purpose, not only ceramic, but also hyper-pressed brick can be used.

Facing houses with silicate brick or stone (see Stone cladding - a practical and durable solution) is also not uncommon. Hollow blocks are called a stone in construction, which differ from brick: both in size and in the presence of a tongue-and-groove joint.

So:

- You ask what is different facing brick from an ordinary brick, because both one and the other have one size range, is it full and empty? The fact is that only a product that has at least two facets: a spoon and a poke can be called facial.

- It can be not only a beautiful relief, but also a surface decorated with the help of shotcrete, engobing, and glazing technologies. The color of the brick can be natural, but often, during the production process, pigments are added to the raw material, resulting in a decorative material.

- Its facial faces may not have any relief. In this case, the decorative effect of the cladding is achieved due to perfect smoothness, and the impeccable geometry of its elements. Clinker brick possesses such advantages: it is fired according to another technology, which makes it possible to obtain a material with higher strength characteristics.

- If we talk about the strength of facing bricks, we immediately note that it is in no way inferior to ordinary bricks - it can also be used for laying bearing walls in the same way. Apart from the appearance of the products, the main difference is their price, so the main wall is erected from ordinary brick, and the decorative wall from the front.

- In any case, the brick or stones are first sorted: products with integer corners and edges of the same color are selected for facing the facades. Everything else, along with a simple brick, goes to the main masonry.

- Of course, at the same time, the cost of walls increases, but if you take into account that you will not need either finishing or repair during the operation of the building, the facade cladding made of bricks will be the most economical. In addition, brick cladding makes the walls more durable, which is also important.

For this reason, the decoration of walls erected from inexpensive cellular concrete is most often finished with brick. This is done according to the system of frameless ventilated facades, but different technologies can be used.

It all depends on what structural material the walls of the building were erected from.We will talk about this in the next part of the article, as well as offer a video on the topic: “Facing a facade with a brick: technology”.

Secrets of brick cladding

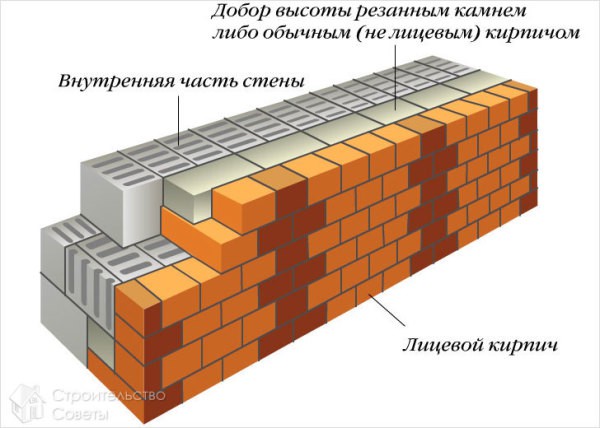

As already noted, a decorative brick wall may be the front of a supporting brick wall. The most common technology for its construction is lightweight or, as it is also called, well masonry.

- The wall is laid out so that an air gap of half a brick forms in its thickness. This gap, right in the process of masonry, is filled with foam or loose thermal insulation material, or sawn stone, as shown in the photo. If necessary, the space can be filled with concrete, obtaining a super-strong wall.

- In this case, the brick actually plays the role of fixed formwork, and the wall is monolithic. Basically, this technology is used for masonry basement walls. The recessed part of the walls is laid out of ordinary brick, and the ground - from the front. In this way, about the finishing department of the basement no need to worry.

- The rigidity of the lightweight masonry is ensured due to its ligation with stitch rows, which is very clearly visible in the picture above. The thickness of the inner wall is one or one and a half bricks, and the outer wall is half brick. Dressing, as well as the reinforcement of masonry, is made in every fourth or fifth row.

- Brick dressing can be replaced with bar reinforcement, or flexible ties. They are laid in the seams of the masonry so that the ends do not protrude outward. When the solution hardens, the rods are tightly monolithic in the masonry.

- Well masonry technology is relevant only when the main and decorative walls are erected at the same time. But brick cladding can also be carried out on the facade of an already rebuilt building. For example, if the walls were erected not from small-format material, but from large concrete panels, or simply, an overhaul of the old house is carried out.

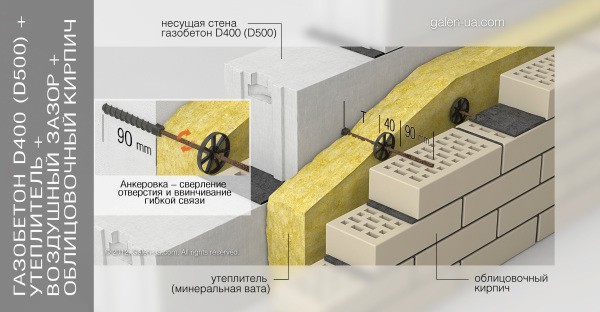

- In this case, the technological map of the facade cladding with a brick requires the use of special anchors for connecting the main and decorative walls. A hole is drilled in the concrete wall where the dowel is inserted, and then the anchor is screwed.

- Its second end will be monolithic in the masonry. The length of such an anchor should be at least 22 cm: 9 cm ends fixed in the walls, plus 4 cm of ventilated space. In this case, it can be filled with slab insulation, only then the anchor should be even longer, given the thickness of the insulating material.

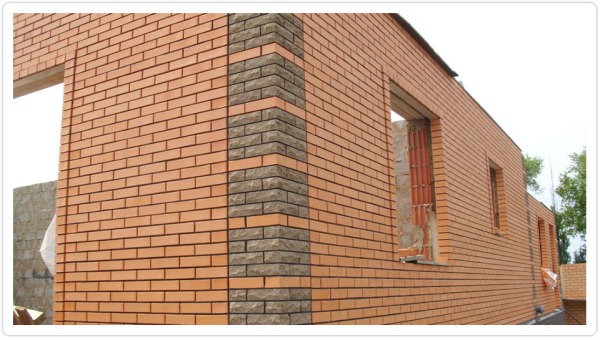

By the way, you can decorate the facade of the house not only with a beautiful texture, but also with the help of various brick-laying techniques - this masonry is called decorative. Professional bricklayers know many ways of laying and dressing bricks.

- Various options are also used for dissecting the lining with vertical seams, the alignment of which can also be very interesting. To decorate the brick walls, relief masonry can be used when the bumps protrude, forming a pattern. This can be a patterned masonry, in which the picture is obtained through the use of bricks of different colors.

- As you see, this work is rather laborious, and it is impossible to do it yourself without any skills. In order to master the decorative masonry, you need to familiarize yourself with all the intricacies of the masonry profession, which concerns not only brick but also stone decoration.

The working form of the finishing stone can be different - it is not only tile, "noodles" or "plastushka". The stones are also cut in the form of bricks with which to wall the walls. By the way, in the regions where they mine natural stone, it can be seen on the facades even more often than brick.

Ventilated frame facades

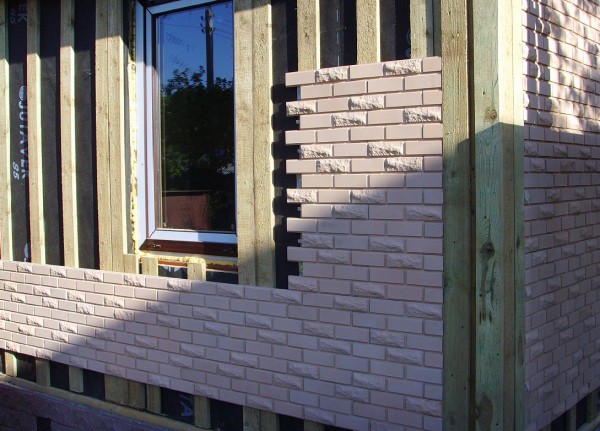

The instructions presented in this chapter will introduce you to simpler wall finishes that do not require professional knowledge. Modern facade cladding is often done with the help of hinged materials.

They are mounted on a crate, the thickness of which provides an air gap inside the structure. This is a distinctive feature of ventilated facades.

- To perform a decorative facing surface, a variety of materials are used, ranging from stone tiles to large ceramic or fiber cement panels (see Paneling of buildings - types of materials and technology) Here, who, and what is enough for imagination and money.

With the help of materials mounted in a frame way, both the facade cladding of a country house and the design of a chic mansion can be made. Take the same stone or brick, which was described above.

A similar decorative effect can be obtained in a simpler and cheaper way - just select the appropriate facade panels.

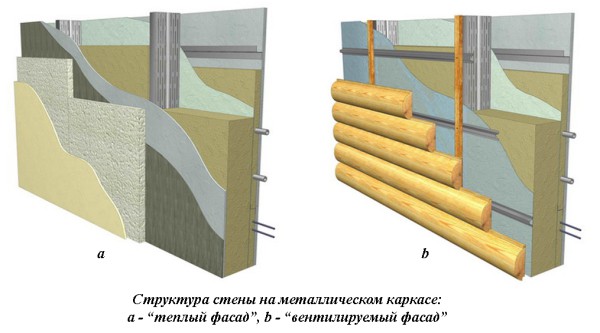

Ventilation Facade Structure

The crate on which the mounted materials are mounted may consist of wooden or metal elements. Their shape and section size are selected depending on the configuration and weight of the decorative material. In principle, nothing needs to be invented here: there are proven technologies over the years, which must be followed.

- The calculator of the facade cladding, as well as auxiliary accessories and crate elements, can be found on the website of each manufacturer or its dealer. So, your main task: to carry out measurements correctly. They measure not just the dimensions of the building, but the perimeter of each wall individually, the height of the floors, the dimensions of the openings and gables.

- The main criterion for choosing hinged materials for building decoration is the need for wall insulation, because if you do this from the inside, the area of the premises is reduced. Installation of heat-insulating material is one of the intermediate technological operations performed after waterproofing the walls and installing the lathing.

- The need for insulation, often makes adjustments to the structure of the crate. In this case, it has to be installed in two tiers: on the first, a heater is mounted, and on the second - decorative material. The upper crate is called remote, it is she who provides the ventilation gap.

- In regions with a harsh climate, insulation can be two-layer, and even three-layer. Accordingly, the structure of the frame changes. Here, much more depends on the type of insulation chosen. In private construction, warming of houses with foam and mineral wool is most often done.

- Maybe not everyone knows about the existence of a new generation of thermal insulation materials, which are made on the basis of foamed polyethylene. These are modern polymeric materials, with one-sided and double-sided foiling, such as: Isolon, Penofol, Aluf, produced both in rolls and in the form of plates.

They cope much better with the task, and the thickness of the layer of insulation material, while significantly reduced. What benefits does this provide?

Firstly, it is possible to reduce the size of the crate elements, and secondly, if there is a reflective layer on the insulation, there is no need to install a vapor barrier. All this significantly reduces labor costs, and more than compensates for the higher cost of insulation.

Attachments

In the final part of our article, we will talk about the most popular materials used today to create and design ventilation facades. The palm, perhaps, belongs to long siding panels (see. Facing the house with siding in accordance with all the rules), imitating a board not only in shape, but also in the texture of the wood pattern on the surface.

- Each manufacturer offers its own range of colors of the material, which allows you to get away from the boring wood gamut, and significantly expand the possibilities for design. Today on sale you can see not only metal and plastic panels, but also products in the production of which multicomponent raw materials, called composite, are used.

- Among the types of siding, there are three types of panels made in this way: fiber cement (cement + fiber), ceramic siding (cement + clay), and composite wood (wood flour + polymer resins).

- Such a mixture of ingredients allows you to get a material with new properties and give it any shape. When mixed, the components endow each other with qualities not previously characteristic of them. And if we take into account that natural raw materials are taken as the basis of the composite, then the imitations on the surface of the finished product are better.

- Siding can not only have the shape of a board, but also be a small rectangular or square panel. A distinctive feature of this material is not the configuration and front trim, but the panel structure, consisting of a locking edge, form factor, and mounting perforated plate.

- Of particular note are materials such as thermal wood (planken) and wood composite. Planken is a natural material obtained by high-temperature drying of wood. At the same time, its structure is so compacted that the tree practically ceases to absorb moisture.

- At the same time, the natural pattern formed by the fibers becomes more noticeable. The hardest types of wood are subjected to this procedure: larch, ash, cedar, oak - so the material is unusually strong and beautiful. Installation of planken is carried out using clamps of various designs.

The position of the elements of the crate on the frame depends on their variety: butt, lap, or with a gap. Planken has one drawback - a relatively high cost, which is from 1750 p. just beginning. Therefore, an alternative was created in the form of composite wood, which is much cheaper and easier to install.

Brick cladding is the best solution for exterior decoration of the facade of the house. The most affordable cost will be silicate brick. So that the facade has a beautiful design, around the openings and corners can be finished with ceramic bricks. Clinker brick will be a more expensive finish, it can be used with a standard thickness of 120 mm, or you can buy a narrow brick with a thickness of 65 mm.