How to drill a hole in the wall with different building materials

Drilling holes in the wall must be done both during capital construction and in everyday life. And in this matter it all depends on the material of the base plane and the diameter of the hole. Therefore, it is necessary to choose the correct material for the manufacture of the drill. After all, there is a significant difference.

The drill for making holes in the brick will not withstand concrete and will simply burn. Today we will look at how holes are made in different materials. Also on the video in this article and photo you can find out the options of the tool and select the one you need.

The content of the article

Which device is best to make recesses in the wall surface

To carry out installation by drilling recesses in our time is quite easy. If a person is trained and correctly uses modern electric tools, then there will be no difficulties. To keep your home clean after work, use a jig that allows you to drill with a minimum of dirt and dust.

It’s easiest to make a hole in the wall with a puncher, which is what professionals recommend using. He will cope with the most durable materials in the wall in the best way and have not yet invented the best. But such a power tool is expensive and not everyone can buy it for home use. An electric drill with the effect of shock will help to make holes in the wall.

Some recommendations for choosing the right drill

Cutting holes in the walls in most cases is done with a drill. This tool is in almost every family, and experts give their recommendations, they will expand the scope of the drill.

Caution: When choosing a drill, carefully read the technical specifications. The power of the appliance should have at least 600 W, and the speed can be no more than 2500 per minute, and this is in the mode of regulation.

So:

- Mandatory reverse, which changes the rotation of the drill clockwise and counterclockwise. Choose a model with a quick-clamping chuck, only then you will not spend too much time looking for a key to replace the drill.

- Do not forget that the device must have a shock function. It will help to cope with any complexity of the wall surface, and drilling holes will be quite easy and simple. That's all, because materials such as bricks, cement or concrete are quickly destroyed by dynamic actions, namely, impacts. If the electric drill is not equipped with such a shock function, then the simplest drilling process will drag on for a long time. The drill will cling to the composition located in the wall and at the same time become very hot, and there will be little sense from this. Here is such a feature as hammer drilling occurs in a completely different way. This is something like chiselling.

How to choose the right drill

Probably everyone saw a huge assortment of different types of drills in stores and in markets. Now we’ll figure out which one is best to use. The wooden, plasterboard or foam concrete surface of the walls is not difficult to drill with the most ordinary drill.

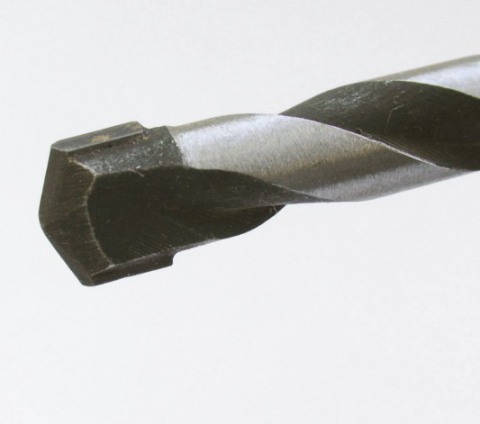

Now, if the material is brick, stone or concrete, it is better to choose a drill made of hard alloys.Unlike the previous one, it has winning cutting inserts. Welded items are visible on the edge.

If your house has at least a couple of such drills with sizes from 6 mm. up to 8 mm is already fine; be sure they will still be needed. With their help, you can make a hole up to 20 cm deep.

When you need to make a large hole, you need to get a drill. They drill dense surfaces almost a meter deep, but only using a hammer drill, a conventional drill will not help here.

So:

- Boers have tails with a diameter of 15 mm. and more, there are grooves that serve for fastening. But if the drill works like a hammer drill, then they are in the chuck quite well clamped. The drill characteristic is located on the tail itself.

- If you need to drill a solid surface, this process is divided into several stages, drilling will take place safely and quickly.

- First choose a drill with a length of up to 20 cm. Designed to a depth of almost 15 cm.

- Next, use a long drill designed for 35 cm.

- Drilling ends with a 50 - centimeter drill. To do this, you need a powerful drill, but note earlier, we mentioned that it is not designed for heavy loads unless for individual cases.

- If buying a hammer drill is not possible, rent it for a few hours.

Attention: Punching holes in the wall d = 150 mm or more is best done with a drill. They are quite large in length and they have a reliable mount in the cartridge.

Safe drilling of recesses in the wall

It is quite possible to drill a hole in the wall with your own hands. But at the same time, everything must be done quickly, efficiently and safely. For different wall materials, there is also their own instruction on the rules for performing work. Read about it in detail below.

Attention: Before starting work, carefully read the surface of the walls, make sure that there are no electric or any other cables in the drilling areas. Hurry and carelessness will damage the wires, and even worse, your own health can be at risk. You ask, how not to get into the cable? Now we will understand everything in detail.

What to do in order not to get into the wire

There are switches or sockets on the walls, carefully inspect their presence. From them, the network wires diverge vertically and go straight to the junction box.

If this is so, then it is ideal, but rarely. Usually, electricians do not always follow the rules in order to save the cable, it is carried out diagonally.

So:

- Most often, devices are used to check for the presence of a cable, their price is not high and the determination is quick enough.

- If you do not have a device, then you should know that the wire is at a depth of 10 mm. To check its presence, very carefully, with the help of some kind of blunt tool, hollow the surface. If you did not find the cable there, then you can safely drill. Experts advise making the recess a little larger, let it be 20 mm.

- Do not press the drill firmly against the wall and inspect every few millimeters for wiring. Also in specialized stores you can buy a special device that determines where to find the wire of the electrical network. Be sure to ask about the quality when buying and choose the best, your own health depends on its proper operation. Also, during normal and folded operation of the device, you can find the place where the reinforcement passes in concrete surfaces.

- A copper wire can be found quickly if it is recessed at a depth of 10 mm. But the aluminum cable is detected only if the device has the function of a metal detector. When searching, constantly look at the indicator, which is equipped with an LED light bulb and it also emits a signal, so be careful, your “assistant” will give a sign.

- In metal detector mode, if the eclectic wire is located, the diode will light up and you will hear a continuous sound. Each normal instrument should have a sensitivity control. The power of the finder depends on the Krona battery.

Attention: Not a single builder involved in the installation of suspended and tension structures on the ceiling surface cannot cope without it. The fact is that the systems are fixed with screws on the ceiling itself, and there are all the electricity cables.

Drilling holes on a reinforced concrete surface or brick

Now we will consider how to make a hole in a concrete wall and a brick one. Brick is easily drilled with a drill.

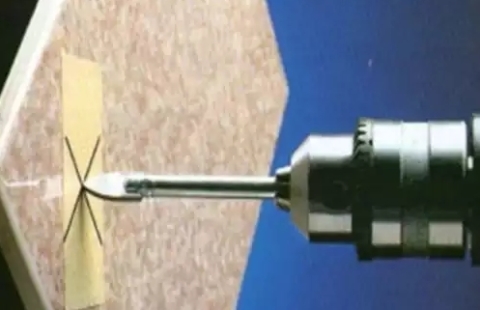

To the place where drilling will be carried out, attach a conductor and drill a slot, the speed of the power tool should not be large, the drill should not overheat.

If the surface of the walls or ceiling is made of durable cement, then it is quite difficult to drill them. Typically, 400 grades are selected, and work is carried out quickly without too much difficulty. Perhaps if the building is still old, then there is strong concrete and the drilling process will be delayed.

- Manufacturers put iron reinforcement into wall panels and blocks for quality - these are such rods with a thickness of not more than 20 mm. and can add crushed stone. With such a task, the drill from victory will not cope.

- There is always a way out, when it became clear that the drill has found fittings, use a conventional drill. If it wasn’t at the right moment, you can move the place for the recess up or down diagonally.

- Granite crushed stone crumble in the wall from impacts of the drill, be careful that during such a process the tool sometimes wedges to facilitate turning the mechanism four turns.

- When the obstruction has departed, continue drilling the surface with a drill with a punch. The puncher and drill will cope with the problem quickly and drilling holes will be much more successful.

Tiled Holes

If you need to make a hole in the tile, use a drill that has welded protrusions and they are made in the form of teeth. This is the crown for drilling tiles.

But sometimes it is necessary to make a small hole and the crown will not work. Then make a mark in place.

- For such a process, select a core, if it was not found, use an ordinary self-tapping screw or a thick clove with a sharp tip. Carefully remove the glaze from the tile where you will drill a hole. In this case, turn the tool turns small, as for a brick surface.

- After when the glaze is removed, then we make a hole with a small drill.

- After that, we expand it to the desired diameter with a thicker drill.

Recesses in the wall of large sizes

When mounting ventilation systems, you need to make a wide recess - 20 mm. Sometimes a counter is hidden in the wall showing the indicators of electricity, then in general you need to make a niche on the surface. In your own home, this is done with a carbide drill.

So:

- Carefully mark with a pencil a wall for a hole. On the wall from the outside, holes are drilled with a drill with a diameter of at least 5 mm. at a distance of 15 mm.

- To deepen to 20 cm, you need to perform almost 30 revolutions with a drill. Only then remove the materials with a chisel or hammer, making a niche of the right size from the wall. If the diameter of the drills is smaller, the edges will be neat, but for this you will need to make a large number of holes.

Maybe there is such an option that the wall surface is quite solid, and in order to get a through hole, the drilling stages are divided into several processes:

- If you can drill a surface on both sides, first do this on one side, and only then do a full through hole. And repeat the steps until the hole satisfies you.

- When it is not possible to drill the wall surface from one or the other side, then do the processes in turn in several steps. From the previously made mark, draw another line, and once you have chosen the wrong material, you can go deeper into the niche with a drill, without touching the edges on the wall. To make work easier, select a long drill bit at the very beginning.

Tips to help you get the most accurate drilling.

It turns out that there is nothing complicated in drilling recesses in the surface of the walls:

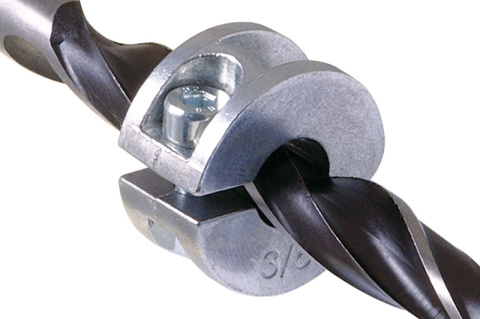

- On the side of the conductor, glue a sheet of sandpaper with tape or glue. Its size depends on the area where the hole will be. Thus, the adhesion of the device to the wall surface will increase and you will accurately make the perfect hole in the right place. It is also quite possible to use a stationary limiter. Its price is not large and can be purchased in retail chains.

- Sometimes you need to drill a hole under the dowel, they can be of different diameters, but usually it is up to 10 mm. It all depends on what you will be hanging and its weight and, of course, on the density of the material in the wall.

- In order for the jig to be universal, drill a couple of holes of the right size in it with an ordinary drill so that the device can be hung.

- You can attach a plate to the conductor, so this shelf protects the surface finish of the walls from dust and debris. You can use this device when making recesses for attaching baseboards to the floor and wall.

- Measure the places on the conductor of the desired size at the selected height from the shelf, and drill holes. In order to make recesses, simply put the shelf on the floor, and all the cracks will be obtained strictly in size and the desired height. Carrying out installation, gradually adhering to the rules, the skirting board will lie tightly on the floor surface.

- If you need to hang on the wall, some kind of decorative element - it can be a picture, a frame for photos and much more, without the presence of an auxiliary conductor you can not cope. The fact is that the holes should be at a clear distance between each other. In general, consider your own wishes and the unified style of the room.

- To do it yourself, the jig that serves for the most correct drilling of holes, pick up plywood or a metal sheet. Make markings on it and make the required number of recesses with an ordinary drill.

Let's consider the option when you need to mount parts not on one screw, but on several:

- The first hole is drilled on the wall, and the second is made equal to the size of the screw. Use a jig for precise recess. And then the dowel is hammered into the hole.

- You can screw the conductor to the wall surface using a self-tapping screw and a dowel, level it with a water level, so your drilled recesses will turn out to be even in one horizontal line.

- Using a simple conductor, which, as you already understood, can be done on your own within literally half an hour, the recesses drilled with a drill will be exactly at the right distance from each other.

- Given this technology, holes can be made over a fairly large gap. To do this, drill the holes first, in the same way as previously discussed, then screw the conductor on both sides with screws and make the remaining recesses with a drill.

Attention: If you think to pass a cable through a hole in the wall, then do it 20% more, because it should lie freely and not be pinched.

How to drill a large diameter hole in the wall you now know. Take your time and mark up correctly. Using the limiters, you will make the desired depth and diameter. The hole in the brick wall is not complicated, but requires accuracy of manufacture.

Tags: concrete