Make an opening in the load-bearing wall: standard and non-standard options

Is it possible to make an opening in the bearing wall and how to do it correctly we will consider in detail. After all, this is not such a simple matter, this type of wall carries a heavy load and it is not so safe to make an opening.

How to make an opening in the bearing wall is described in detail below. Also on the video in this article and photo you can get additional information you need.

The content of the article

Legalization of redevelopment

When thinking about how to make an opening in a supporting brick wall, you should immediately take into account the documentation. After all, this is an important point.

According to the current legislation, redevelopment with a change in the supporting structures is prohibited. This will need to be agreed.

So:

- A detailed plan of the proposed changes in the building plan is attached to the application.

- The permit issued will allow you to contact the design office to develop technical documentation for the planned project. The finished project is coordinated in a number of permitting commissions - fire, gas, housing and communal services.

- The agreed project is finally approved by the controlling organization. Only after the last resolution can we begin to carry out the planned construction work on redevelopment - the eruption of the opening in the bearing wall of the building.

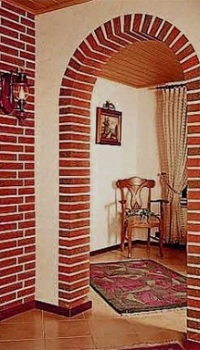

Examples of openings and their finishes

It can be an opening in a prefabricated house, or a brick one, it does not matter. It should fit into the overall interior of the room. First of all, you need to choose the option you want and only then will you be able to get to work.

Let's look at what they are doing and it is likely that this option will suit you:

- An example of finishing a doorway with extras

- The use of stone for the opening

- Clinker tile finish

- Wood Finish

- Drywall decoration

- Modeling in the design of the opening

Redevelopment Security Factors

Any work with the supporting structures of buildings must be thoroughly verified and calculated. The walls of buildings are under tremendous strain, so you need to approach the design of the opening thoroughly. Poor redevelopment with a violation of technology can lead to a partial or complete collapse of the house.

When calculating the most important factors affecting the final result are taken into account:

- Materials used in the construction of the building

- The technical condition of the house, especially the floors

- Wall thickness

- The load on the construction site in which the passage is planned

- Interior layout

- Dimensions of the planned opening and its compliance with the dimensions of the wall.

A calculated project, taking into account all the necessary factors, is agreed in the supervisory service. Doorway transfer operations are only started after the project is approved.

Opening options

The complexity of the calculations when designing the transfer of the doorway in the bearing wall depends on the configuration of the planned opening. The complexity of construction work and the procedure for their implementation directly depend on the chosen option.

| Standard straight opening | Cutting through in rebuilding from scratch. The calculation takes into account the existing doorway, which takes part of the load of the supporting structure. According to the project, such an opening is left untouched or laid with a brick |

| Archway opening | They are more difficult to fulfill - the calculation takes into account the bend trajectory. Of particular difficulty are the calculations of the arched opening in the brick wall, taking into account the placement of masonry joints |

| Partial carryover | Assumes the jumper of the existing passage in the right direction.

|

Hole cutting equipment

Cutting openings in the bearing wall is performed with a special tool. Conventional hammer hammers, perforators and grinders will not work for such a complicated procedure - they create too much dust, replaceable parts quickly wear out and break, excessive vibration leads to the formation of cracks and chips on the walls.

Cutting openings in the bearing walls is carried out:

| Wire cutting machine | As a cutting tool, a special rope is used, on which diamond-coated bushings are worn. The rope is designed for tremendous tensile loads. The installation practically stretches the rope through the cut structure. Dry and wet cutting is used. The second option helps to avoid heavy dust. |

| Diamond Saw Blade Hand Saw | Water is supplied to the cutting site to cool the tool and prevent excessive dust |

| Wall saw machine | Acting on the same principle as a hand saw, but designed to work with thick walls. It uses running water for cooling. |

| Diamond drill tool | The cutting tool is a special cone-shaped drill with a diamond coating. This tool is also used to drill holes in the walls for laying various communications. |

We make an opening

Preparatory phase: strengthening the future opening

Construction work on changing the design of load-bearing walls is carried out strictly according to the approved project, taking into account the structural features of the building. The main objective of the project is to maintain the integrity of the structure after moving or punching a new passage.

Before starting work, an advance strengthening of the design of the planned opening is performed. To do this, cut the strobes along the perimeter of the passage, into which the fittings (channels) are cut by a chaser.

The strobes are not through - they are recesses for the reinforcing element. The cross-section of the channel is calculated taking into account the various structural characteristics of the building.

Attention: The channels are laid in the recesses made by a chaser, on both sides of the partition. To make the bookmark location exactly the same, mark the planned passage on the wall. Through the marking, through holes are drilled and the drawing is transferred to the other side of the wall.

- The channels used to strengthen the structure are pre-cut to the desired length, taking into account the height and width of the planned opening. It will take two pairs for the side parts of the opening and two pairs for the upper and lower parts. On each pair, holes are made in advance through which the channels will be fastened with studs or self-anchors. The distance between the holes is calculated by calculation.

- Alternately set the side pairs in the strobes. Through the holes made in the channel pairs, a rest is drilled under the fastening hardware. Couples tighten fasteners. Important: Fasteners must be tightened securely using special power tools or improvised materials.

After installing the vertical channels, the operation is repeated with horizontal pairs. Joints of horizontal and vertical channels are fastened by welding on both sides of the future opening. The preliminary strengthening of the opening is ready.

Milestone: cutting the load-bearing wall

After completing the preparatory phase for strengthening the load-bearing wall, they begin to pierce a new doorway. The complexity of the work depends on the material of the walls. Brickwork is the easiest to dismantle - it is cleaned row by row. With a concrete wall, there will be more problems during dismantling due to the presence of reinforcement in the structure.

- To cut an opening in the wall, a hand saw with a diamond blade is often used. At the place of the future opening, marking is applied, dividing the passage into small blocks. By marking the tool, slots are made on both sides of the wall. The depth of the slot can reach 15 cm on each side. Next, the blocks are alternately removed from the opening layer by layer. When dismantling, additional use of a rotary hammer is often required.

- When cutting through the opening with a wall saw, the depth of the slot reaches 60 cm, but during operation access to running water is required to cool the tool and wash concrete chips and dust.

- Sometimes the wall thickness of the building is quite large, especially if the opening needs to be cut through in the foundation or in the facade. In this case, a rope installation is used, capable of quickly cutting through concrete or monolithic blocks of any thickness.

- You can make an opening in the wall in the third way. To do this, according to the markings on the wall, drill holes are drilled with a diamond drill. Next, you only need to saw into pieces the cut out fragment and remove pieces of the wall from the opening.

- Modern tools for cutting openings in load-bearing structures allow you to perform work in a short time with minimal noise and dust.

The final stage: strengthening the structure

An aperture cut in a load-bearing wall requires final reinforcement using welding and general construction works.

The work is carried out in several stages:

- The parts of the channels along the perimeter of the opening that were inaccessible before the dismantling of the wall are welded. Important: weld legs for welding should be at least 6 mm, in accordance with established standards.

- Channel pairs from different sides of the wall are connected by transverse steel plates, not more than 50 mm wide and not less than 4 mm thick. The plates are welded to the channels along the perimeter of the structure with a step of about 30-40 cm from each other.

- A metal mesh is welded onto the channel, on which the plaster is applied (seeHow do plastering do it yourself) The integrity of the damaged plaster coating of the wall is restored - all potholes and depressions are closed, the channels are additionally strengthened with cement mortar.

Attention: Working with special tools for cutting openings in load-bearing walls requires special professional skills. When operating the equipment, safety rules must be observed: work in protective clothing and protect your hands from rotating parts of mechanisms.

- At the end of the redevelopment work - the eruption of a new passage in the supporting structure of the building - the changes made must be recorded and put into operation.

- For this, the selection committee of the housing organization will draw up the relevant act. The document must be certified by the representatives of the project office that developed the project, the company that performed the work, and the organization that took the facility into operation. After approval in all instances, the redevelopment will be officially legalized.

How to make an opening in a bearing wall you now know. Its price will depend on the size of the opening and finishing materials. Everything can be done without problems with your own hands, this will reduce costs. And the instruction will help you not to miss anything.