Mosaic of a cast-iron bathtub - how to do it

Modern steel and acrylic bathtubs - light, beautiful, graceful - could not be forced out of the market their ancestors, which are products from heavy cast iron. Without focusing on the operational characteristics and positive qualities of the cast-iron bathtubs, due to which this happens, let's think about how to renew the old font that has lost its original appearance with mosaic tiles.

The content of the article

Types of facing mosaics

Cladding with a cast-iron bath mosaic is too expensive a pleasure, since the material itself is very expensive, and a lot of time is spent on such work. It’s easier and cheaper to just buy and install a new bath.

Such a decision is justified only if the font cannot be dismantled without prejudice to wall cladding and gender, especially if it is expensive, and can last for more than one year. Therefore, instead of a real mosaic, a mosaic tile is usually used, which is a matrix of small elements glued onto paper or a mesh substrate - chips.

There are several types of this material - stone, ceramic, concrete, glass and even metal mosaic tiles, but only ceramic and glass are suitable for bathtub lining.

Ceramic mosaic

It is made from the same clay mixture and using the same technology as ordinary ceramic tiles. The composition introduces additives that give the material strength, texture, color and luster.

After molding and firing, small square (less often other shapes) elements are glued with the reverse side to the fiberglass mesh, which remains walled up in glue during installation. Thanks to the mesh, which is easily cut with a knife or scissors, but well resists tearing, the mosaic elements are securely fixed relative to each other, and the tile gains flexibility and can take any shape.

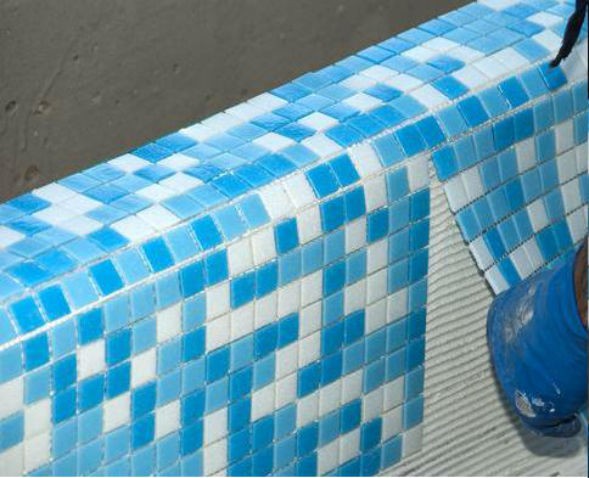

The appearance of the lining at the end of the work will not differ from the finish with a real mosaic (seeMosaic decoration of various manufacturing methods), but the installation process itself will be less time-consuming, and the price is much lower.

Note. The matrix can consist of elements of the same color or include mixed shades arranged in random order or with a smooth transition from dark to light. The surface can be smooth or embossed, matte or glossy.

The main advantages of ceramic mosaics:

- Ecological purity of raw materials, safety for health;

- High moisture resistance and water resistance, which is very important, since the cladding will be affected not just by increased humidity, but water directly;

- Practicality, low maintenance requirements. The surface does not absorb dirt and is easily cleaned using detergents, including abrasive ones;

- Strength. Due to the high density of the material, which is achieved in the process of high-temperature firing, it withstands severe mechanical loads;

- Wear resistance, preservation of the initial appearance of the surface and structure of the material;

- Durability. Covering the bathtub with mosaic, subject to installation technology and operating rules, will last you 20 years or more;

- Resistance to high and low temperatures without loss of strength and appearance.

The advantages of ceramics include fire resistance, but it is hardly important in the bathroom.

Glass mosaic

The manufacturing technology resembles the previous one - liquid molten raw materials are also mixed with colored pigments and additives, which give the material certain strength and other properties, and then undergo firing. Finished tiles can also have a matte or glossy surface, various color schemes.

Tip. The basis of glass mosaic tiles is often thick paper glued to the front surface. It does not matter if the lining of the bathroom with a mosaic involves finishing only smooth surfaces - walls, floors, rectangular shower trays, screens. For restoration of the bath itself, it is better to take tiles on a mesh basis.

Glass mosaic has almost all the advantages of ceramic. It is also water resistant, does not respond to low and high temperatures, is easy to clean, does not absorb dirt and does not lose aesthetic properties for a long time.

But her strength is lower - when heavy objects fall on the surface, it is easily damaged. Another drawback is the risk of injury during installation and operation.

When cutting tiles to fit them on complex curved sections, sharp edges are formed that are easily cut.

Tip. To avoid this, cut the tile not with a tile cutter, but with a grinder with a diamond disk. It will grind and smooth sharp edges.

How to mosaic a bath

Regardless of whether you clad the bath inside or outside, the installation principle and the materials and tools used are similar.

What is needed

From the tools should be prepared:

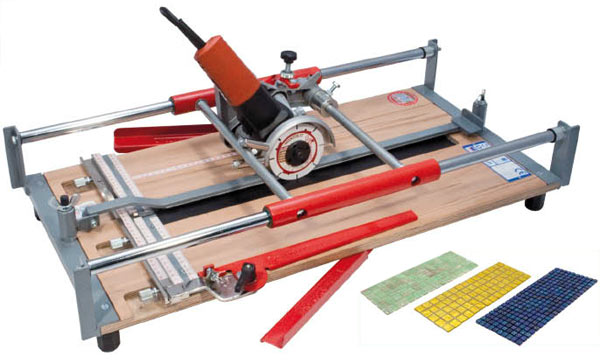

- Tile cutter, special nippers for mosaics or a small grinder with a diamond disk;

- Scissors or stationery knife for cutting the substrate;

- Measuring tool - tape measure, ruler, marking pencil;

- Spatula for applying glue, including flexible rubber for processing curved sections and grouting.

As for the glue, for the exterior finish you can use a standard tiled or liquid nails. And here mosaic cladding the inside baths are made with special glue for pools, which has high adhesion.

You will also need grout for joints. It must be of high quality, waterproof, since its destruction by moisture can cause the appearance of fungi and the destruction of the entire surface.

Installation

Before starting work, it is necessary to prepare the surface: thoroughly wash it with chlorine-containing agents that destroy microbes, degrease and dry.

Installation instructions:

- Begin work with facing even surfaces - sides and bottom of the bath;

- Apply glue with a notched trowel with a tooth height of about 4 mm on the area to be trimmed, level it so that the thickness of the glue is the same everywhere;

- Apply the tile and evenly press it to the base, smoothing with your hands or with a wide rubber spatula;

- Try so that the glue does not protrude strongly from the seams, immediately remove its excess with a wet sponge so that there is room for grouting in the seams;

- When all the straight sections are finished, go to the rounded corners, starting the lining from the middle and moving to the edges;

- This is a very painstaking work, requiring careful measurements and adjustments, cutting tiles not only on the grid, but also on the chips. So that the glue does not dry out, apply it only to those areas that are being finished at the moment;

Tip. Do not discard cut pieces, they can come in handy for filling the smallest and narrowest sections.

- After finishing the lining, let the glue dry and gain strength in accordance with the manufacturer's instructions. Then it is possible to grout the joints, rubbing it into the surface with a rubber spatula in the direction diagonal to the sides of the chips;

- The last stage is cleaning the surface with a wet sponge from the remnants of the grout.

Outside, the bathtub is faced in the same way. Some masters argue that it is easier to do this by placing the tiles diagonally - it is easier to veneer the rounded areas, so you get fewer trim.

Conclusion

Just like that, you can give a second life to an old cast-iron bathtub, which over the years has lost its former chic, but has not lost its excellent performance properties. After watching the video in this article, you better understand the installation technology and can cope with it yourself.

A very interesting mosaic theme. He wanted to change his old yellowed cast-iron bath. In this way, it can be made almost eternal, just change the mosaic every twenty years and that's it!

It’s very beautiful, I’ve seen it with my friends, but I don’t know yet whether I will dare to do it myself. It is not at all a matter of price or the complexity of the work. Just such a bath requires special care and special silicone grout for joints. I hope that limescale will not settle on such a grout. Here is a little more to observe how this bathtub behaves with friends, and then you can do it yourself.

The question may be silly, but is glue + grout safe for health? We love to lie in the water longer, and I really liked your option of saving the old bath!