How is a rough floor in a frame house made?

The article “Rough floor” describes the flooring scheme without taking into account the features of the building, general instructions. But in order to imagine how to properly lay the rough floor of a frame house, it is important to know the specifics, what are the differences from other types of buildings. The time for constructing a rough floor in a frame house comes earlier than the house itself is ready - right after the foundation, ahead of the frame of the walls.

- Assessment of the area.

We begin by assessing the area in which the house is located. We will be interested in the depth of groundwater under the foundation and the climate. The first factor affects the number of floor layers - 1 or 2, and the second - on the choice of wood. - Floor load.

Also, before making a rough floor in a frame house, we will think about how intense the load on the floor structure is supposed. What is passability, how much furniture and heavy household appliances will be in the room. If we are constructing a rough floor in a frame shed, for example, we estimate the approximate weight of the stored equipment. If the foundation of the frame structure is not columnar, we begin by erecting pillars - supports - of brick or concrete at a distance of about a meter from each other. Sometimes the step reaches almost 2 m, but more retreat is not recommended. We will lay the lags on the lower harness, so we fasten the binding boards with screws, starting from the inside, ending with the outside. In the finished strapping, we cut out the grooves for the log with the help of a jigsaw. - We put the lags.

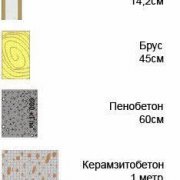

The construction of the subfloor in the frame house continues with the laying stage of the lag. Both boards and bars are suitable - the choice is determined by future floor loads. Protect the cranial bars, which are located at the height of the lower cut of the log, with waterproofing laid in 2 layers so that the wood does not absorb moisture from the soil through the capillaries. Before installation, carefully process all lumber with antiseptics and flame retardants. Or the universal composition - a comprehensive "Fire protection". - Insulate the floor.

When the lags are in place, we take up the insulation. Expanded clay is considered to be popular bulk insulation for frame houses - the current leader: slag, dry sawdust, perlite (widely used before). Let's make a reservation right away - because of its weight, expanded clay is suitable only for basement ceilings. What is higher is better to insulate with light ecowool. An alternative to granular heat insulators is rolled and slab mineral wool or polystyrene foam in the form of sheets. Reliable sprayed insulation made of polyurethane foam is more expensive due to the fact that the components cannot be performed on their own and sheets of plywood, OSB or tongue-and-groove boards are laid on top - the latter option sometimes does not require a finish coating, only processing a wooden surface. Then the walls of the frame should not be placed on the boards, installed on the logs. After the boards lose their operational characteristics, replacement is not difficult. - The choice of materials.

When making a rough floor in a frame house with your own hands, choose the material of the top layer of the structure based on the presence of assistants. The boards are screwed longer, cracks will inevitably be in the draft floor and squeaks are possible, but they are easy to carry alone. But to move heavy plywood or particle boards, you will need at least 2 people.

When it is planned to equip the system with underfloor heating, a concrete screed over plywood will be a good option. Heating pipes are laid in this layer, the main thing is to carefully insulate the screed layer from the stove. In other cases, the finish flooring is also dispensed with without filling the subfloor.