Concrete staircase: facing with wood - advice from the masters

In modern building repairs, there are many ways to self-finish stairs. One of them is a concrete staircase lining with wood.

This method is ideal for stairwells, which during the operational period have lost their external aesthetics. During the restoration work, the decoration and lining of the handrails is recommended.

Finishing work can be done with your own hands.

The content of the article

What material is used for decorating

For this type of work, as wood cladding The use of different types of materials is recommended for concrete stairs, each of which is good in its own way and has a number of features.

Consider the materials that concrete staircases are lined with, in addition to wood:

- The most common method and a great alternative to wood is laminate.

- But the material is not particularly suitable for stairwells. Due to the small area of the stairs, the technology of laying the laminate is disrupted.

Tip. The price of finishing the stairs with laminate is much lower than wood, so many choose this material.

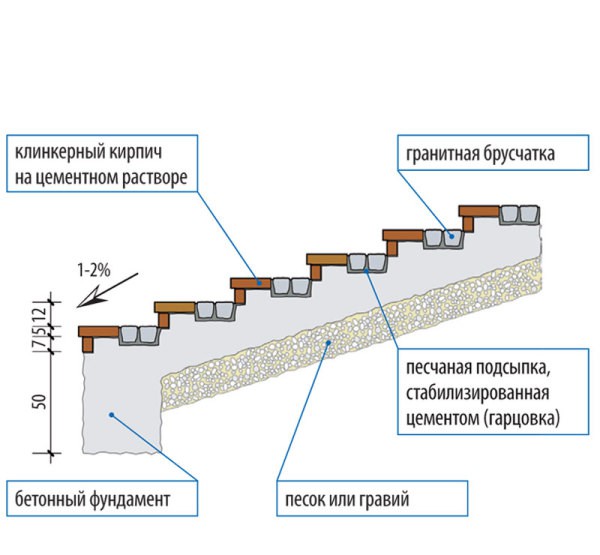

- Next, consider the method of finishing tiles. Natural stone, granite, marble can be attributed to the same category. All materials are linked together by the high cost of design.

- Materials are available specifically for finishing stairs with a rounded edge for risers. This option can ensure the durability of the finish and safety during the period of operation.

And finally, a concrete staircase, lined with wood. This is a popular and durable way.

If you follow the technology for decoration, then the tree will serve for decades.

Preparatory work before finishing

Before being produced concrete staircase lining do-it-yourself tree, you will need to make a series of preparatory work. It is especially important to eliminate a number of particularly pronounced shortcomings and defects.

Tip. In order to inexpensively eliminate all the deficiencies, you can use a solution of cement and sand grade M150.

Instructions for use:

- With the help of the solution, all pronounced defects, including cracks, are filled. Of the tools you need a spatula.

- Before applying the solution to the surface, it is recommended to use a PVA primer.

- In order for the steps to merge with the wall, it is necessary to mount narrow panels of veneered plywood of 1 cm at the bottom.

To decorate the flight of stairs with wood, you will need the following tools:

- Electric drill.

- Screwdriver.

- Hammer.

- Grinding machine.

- Milling machine.

- Saw or small hacksaw.

- Electric jigsaw.

- Plumb or construction level.

After carrying out the necessary preparatory work, you can begin to finish.

Cladding a concrete staircase with wood, video tutorial and installation details

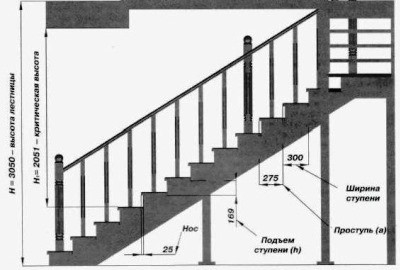

In order for the staircase panels to be located on the same level, it is necessary to make markings using a building plumb. Marking is done in the lower, upper and middle parts of the march.

Work:

- In order to make a markup, you will need to make an indent to ½ of the width of the tread towards the landing. The material is adjusted locally.

Tip. You don’t have to waste time until the solution with which the irregularities were fixed hardens, and install the risers and tread.

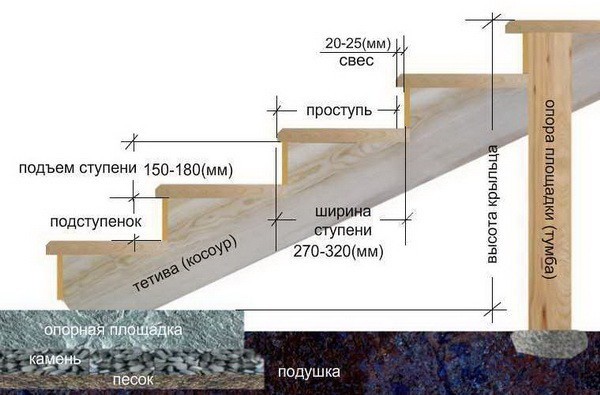

- Traditionally, the width of the treads is considered to be 27-32 cm, and the riser is 15-18 cm.

What wood is used for finishing stairs:

- For such work, the use of hardwoods such as beech or oak is recommended.

- Treads 32 cm wide and 4.5 cm thick are made of the selected material.

- For facing work, you need material 2.5 cm thick and 17.8 cm wide.

Note. These are not standard sizes, it all depends on the design of the march. Self-tapping screws are used as fasteners.

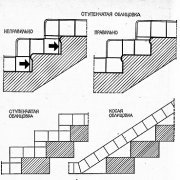

Installation is carried out according to a certain technology:

- Initially, the lower part of the riser is attached flush to the lower part of the tread.

- The upper part of the riser goes into the back of the tread in the groove (it is done initially with the help of a milling cutter).

Note. The depth of the groove should be 1.4 cm and the width 2.5 cm. For evenness of the groove, a flat rail or side stop is used.

- For reliability and rigidity, it is recommended to use metal squares.

- If you mount the corners on the back, then additional sockets are made. Rigid fastening is allowed only from the side of the tread.

For insulation work:

- For additional insulation, some apply polyethylene foam before finishing work.

- The thickness is 0.3 cm. This will reliably protect the structure from damage and noise.

Collection of each separately prepared unit:

- If the wooden structure was constructed one unit at a time, it must be assembled and installed on concrete staircase.

- Work is carried out using screws long in size, 2 pieces on each side.

- For installation in the riser, holes are drilled and marking under the dowels is made.

- Installation is made from the lower riser. Next, the next unit is installed using the installation control in the finished groove.

Attention. It is important to observe the correct location of the groove and the evenness of the installation, after which the structure is fixed with self-tapping screws.

After collecting the entire structure, it is necessary to correctly install the last riser to the flight of stairs. You can connect with a corner or close the top with a wooden board.

How to assemble wooden handrails

The grab handrails for concrete stairs are finished with hardwood. Before starting work, it is necessary to determine the shape and style of future railings.

Let's consider in more detail:

- Basically, most of the structure contains rectangular shapes. Therefore, for the manufacture of not require much effort.

- Basically, difficulties can arise in the manufacture of curved shapes.

- Such assembly is carried out by gluing individual elements at different angles.

Note. Work must be carried out at the installation site.

- To collect the railing and install them on a metal railing, you will need a milling machine.

- In order to cut the connecting elements, a hacksaw with small teeth is used.

- Handrails and handrails are fastened together with screws. After all installation work, the fasteners must be sanded.

- To make the design more attractive, you can use plugs or putty for fasteners.

Upon completion of all work, the structure is varnished or painted.

Recommendations and Tips

The most important and important thing when facing concrete marches with wood is the observance of precise technology, otherwise, the durability of the structure will be significantly reduced and will lose its attractiveness.

Let's consider in more detail:

- If finishing is done with your own hands, be sure to watch the training video and coordinate the details with knowledgeable craftsmen.

- There are cases when the sizes of marches are different, then it is recommended to trim the finishing elements according to the highest design.

- The rest are aligned using a special mixture.

Tip.If the discrepancy involves more than 4 cm, then it is recommended using plywood to make the formwork and the steps are filled.

- In order to minimize moisture absorption in the wood, it will be necessary to install plywood substrates before finishing.

- If you want to emphasize the texture of the tree and give a peculiar look, you can use a stain.

Also, if desired, a laminate can be used instead of wood, but it should be remembered that the installation technology of the laminate will be slightly disturbed. Marble, stone and tile are also used to finish concrete staircases.