Wood staircase trim: trim options and general recommendations

Quite often, facing the stairs with wood. This makes it possible to give a unique exterior design.

The content of the article

Types of stairs on which wooden cladding can be performed

At the moment, the stairs are made:

- Of metal.

- Monolith.

- The brick.

- Wood.

Note. All these materials are durable and can serve as the basis for wooden finishes.

In appearance, the staircase can be:

- Angular.

- Screw.

- Straight.

The methods of miscalculations and the construction of such structures are different.

Elements of the stairs, which are exposed to wooden trim and consist of:

- Bowstrings.

- Handrail.

- Steps.

Finishing exposed:

- Steps.

- The distance between them (bottom edge).

- Handrails.

- Wall spaces near the stairs to create a holistic design.

What types of wood are used for staircase finishing

Today, wood cladding of stairs can be carried out using:

- Oak.

- Mahogany.

- Larch trees.

- Alder trees.

- Ash.

- In rare cases, bark is used to decorate the space near the structure.

Note. The wooden finish can be attributed not only to the use of whole wood species in the work. Laminate staircase cladding is also widespread.

- The most common is considered staircase lining oak.

- This wood species is quite durable and has a beautiful cut.

- Oak boards are mounted quickly.

- Their thickness can be from 1 cm or more.

- They are laid mainly on the stairs.

- Top must be varnished.

Tip. Any species of wood is able to respond to a humid environment and is exposed to dirt and dust. To protect it, use the varnish that covers its surface.

It is also worth considering that oak staircase lining can only be done on a concrete structure that is not able to respond to fungal diseases, unlike metal.

Benefits of Wood Stair Cladding

Wood is an environmentally friendly material.

It has several advantages:

- Practicality.

- Strength.

- Reliability.

- Durability.

Tip. It is not recommended to use the wood cladding of the staircase in rooms with high humidity.

This is due to:

- The tree absorbs moisture well.

- For this reason, its structure is destroyed.

- It loses its properties and characteristics.

Note. Due to environmental friendliness, the price of wood is quite high.

Through the use of wood in decoration stairs, the design takes on an attractive appearance, see photo.

The tree for facing the stairs is pre-processed:

- Natural or mechanical drying.

- Processing with special antiseptic agents to increase resistance to fungal diseases and insects.

- It is best to use wood that has undergone natural drying.

- Moisture came out of this material gradually.

- At the same time, wood has no internal deformations.

Recommendations:

- Mechanical drying is quite rare.

- It can only be resorted to if an ambulance wood cladding is required.

- After it, the material can be with a lot of internal deformations.

Finishing metal stairs with wood

The wooden cladding for stairs made of metal is based on the characteristics of the structure.

So:

- Steps metal stairs can be made of pipe or corner.

- The finish of both those and those steps is different.

- When a tree is lined with steps of their metal pipes, the material is laid on the surface of the metal.

- If the steps are made of a metal corner, then the steps of wood are inserted into them and securely fixed.

For work you will need:

- Wood that has not yet been varnished.

- Screwdriver and punch for screwing material to metal.

- Wood and metal screws.

- Hard putty on wood.

- Sandpaper.

- Varnish and brushes.

In the video you can see how the wooden lining of the steps of a metal staircase is carried out.

Also worth considering:

- If the metal staircase does not have an additional decorative finish, then not only is the facing of the upper part of the steps performed.

- The holes between the steps and the end face of the structure are exposed to decoration.

There is another type of metal staircase in which steps are not made of metal:

- The steps are mounted.

- They are mounted on special indents in the form of a pipe with a small burdock (metal sheet).

Tip. Wooden steps are fastened only from below to a metal sheet with screws so that it is possible to dismantle them if necessary and carry out restoration or repair.

You can screw such steps to the stairs with your own hands.

Recommendations:

- As a rule, metal railings go on a metal staircase.

- Their racks can be made of wood to give unity to the design.

Tip. Since the facing of stairs with wood is carried out with unpainted material, after installation it is worth covering its surface with varnish. You can use special dimming agents that will change the shade of wood.

- Everyone can paint the surface of the wood.

To do this, use:

- Lacquer.

- Brushes.

- Rollers.

Tip. Previously, the surface of the tree is treated with sandpaper for cleaning.

Facing monolithic stairs with wood

Facing wood with monolithic stairs is a little easier than metal.

So:

- Monolithic stairs are made of concrete mortar.

- They already have an even surface of steps and an even angle of the lower edge.

- The surface of concrete is primed before such a finish.

Tip. Facing with a tree of monolithic stairs is carried out only on a cleaned surface.

Initially:

- The surface finish of the monolithic staircase is cleaned.

- To do this, use special detergents.

- Previously, dust is swept away from the surface of the stairs. You can use a vacuum cleaner.

- Then only the monolith is primed.

- The primer must be absorbed into the concrete. For this, several hours pass.

To properly apply the primer there is a special instruction. According to her, all actions are performed.

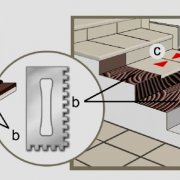

The cladding of monolithic stairs with a tree is carried out using:

- Puncher and screwdriver.

- Roulettes and building level.

- Jigsaw or saw.

- Wood screws and dowels.

- Hand tool.

Tip. For finishing monolithic staircases with wood, a layer of insulating material is previously spread on the surface.

- I need a wooden finish for the reason that the tree breathes and if the air does not go out from under the finish, the structure of the wood will begin to collapse.

- It can cause insects.

Note. Cladding a monolithic staircase with a tree is easy to do on its own.

Recommendations:

- You can use for this not only self-tapping screws and dowels, which are screwed into the wood and securely press it to the concrete surface.

- Also use concrete mortar or special glue on which wooden boards are mounted.

Tip. The last way to install wood trim can only be used with horizontal cladding.

General recommendations before carrying out wooden facing of a ladder

Before you build a staircase, you first need to think about the methods and methods of facing it.

So:

- If you choose the wooden finish of the staircase, then it is worth considering its parameters.

- Each step has its own height. The optimal step height is 25 cm.

- When wood is trimmed, their height will change.

- This is due to the fact that wooden boards have their own thickness.

- The bottom edge trim is also taken into account.

Tip. For wood trim the lower edge uses a material of small thickness of 1 cm.

- The bottom edge is attached close to the bottom of the step.

- The steps themselves can have a small indent of 3-5 cm.

- At the same time, they will be with rounded edges - safety measures of the structure.

Instead of whole wood, laminate is also popular. Its methods and methods of fixing to the surface are different.