Roof cornice: how to finish siding

In order for the roof of the built house to acquire a finished look, it is necessary to make a binder of the overhangs of the roof and cornices. The appearance of the entire facade depends on how clearly and accurately this is done.

In our article, we will talk about how to finish roof eaves with siding, about the properties and characteristics of this material.

The content of the article

What is siding

This term defines not so much the material itself as the technology of decorating facades with panel panels equipped with latches for fastening and holes for nails. This technology was first used in the middle of the last century, in America.

Having become extremely popular in other countries, siding appeared in Russia in the nineties.

So:

- There are several types of siding panels: metal, vinyl and polyvinyl chloride. Metal battens are often used to cladding the facade. Their configuration is somewhat different from those models that are used for hemming roof eaves.

- Finishing roofs and cornices with siding, can be performed both metal and vinyl panels. The main thing is that they are specifically designed for this.

- Siding panels for filing roof overhangs differ not only in shape - they have perforation along the entire length. The perforated surface prevents condensation from collecting inside the siding body.

- PVC panels, which are also called “plastic lining”, can be used not only for cladding facades, but also for finishing balconies outside and inside. Low price helps to increase consumer demand for this material.

All types of panels have a long service life. They are resistant to temperature extremes, ultraviolet, do not require special care during operation.

An extensive color palette and the presence of all kinds of decorating elements allows you to update the facades of any buildings, as well as create new, modern projects.

Mounting technology

Today, roof eaves are everywhere finished with siding, thanks to its undeniable advantages. This is facilitated by a beautiful, aesthetic appearance of the surface, and ease of installation.

It is not particularly difficult - a detailed instruction from the manufacturer will help you do the work yourself. There’s nothing to think of here.

Frame

To be able to fix the panel on the eaves of the roof, it is necessary to make a frame. It can be made of both aluminum profile and wood.

To make a wooden frame, bars with a rectangular section of 25 * 50 mm are used, which are pre-coated with an antiseptic solution.

So:

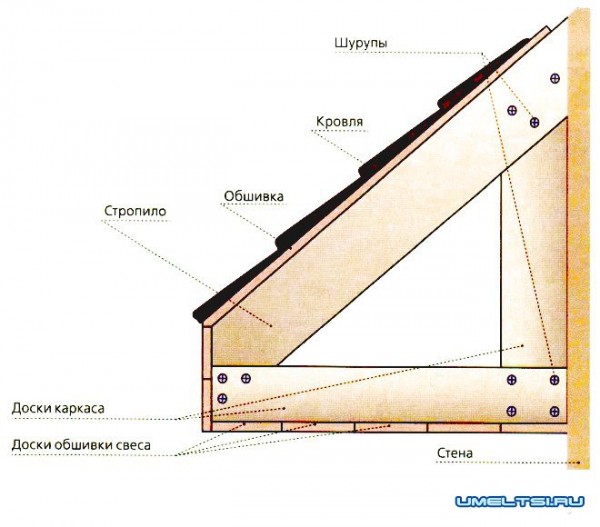

- On roofs with a slight slope, the bars are stuffed directly on the rafters. To make the plane smooth, first mount the extreme bars along which the cord is pulled. And then the remaining details of the frame are also stuffed on it. For clarity, watch the video.

- For pitched roofs with a large slope, the frame is made of two edged boards 100 * 30 mm. The first is nailed to the rafters from below, the second is mounted to the wall in the place where the rafters go beyond its border.

The surface of both boards should be at the same level. - Then, transverse bars are mounted on these boards with a step of 40 cm. Siding will be fixed to them. The photo clearly shows how it looks in section.

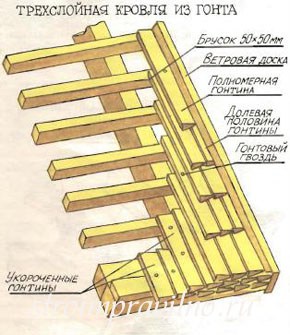

- Along the entire gable overhang, a wind board is nailed to the ends of the bars, and then another one - to the wall of the house, parallel to the slope. All this is done at the stage of erection of rafters.

To make the crate smooth and beautiful, the ends of the bars and legs of the rafters must be cut so that a clear line is formed.

Installation of spotlights

Siding decoration of the roof cornice begins after the crate is ready and the facade is insulated. In this case, several types of fasteners are used.

So:

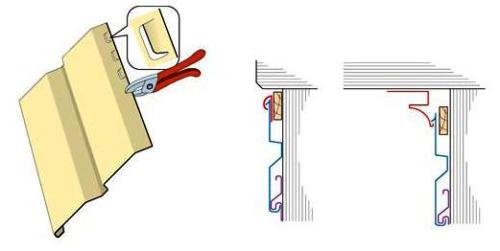

- Like any work in construction, installation of siding begins with markup. Using a level, horizontal marks are applied to the frame with chalk. On these marks and set the starting rail, at a distance of 15 cm from the ends of the walls.

Starting rail

- It is used to fix the bottom row of spotlights to the wall. The siding panel is completely inserted into the starting bar.

In this case, a click will mean that it is securely locked. - J-rail is necessary for vertical fixing of siding at the junction of the cornice with the wall, at the corners, when facing the pediment. It is she who ensures the completeness of the design.

- Finishing strips are mainly used for cladding facades, for closing trimmed to the ends of the panels. Depending on the design of the roof, such rails may be needed when covering the overhang of the roof.

- When covering the cornice, details are also used that form the external and internal corners.

- For the installation of siding, only stainless steel nails are used - aluminum or galvanized. They should have a wide hat and a length of at least four and a half centimeters.

Of the tools at hand you need to have a hacksaw, a square, a tape measure, a hammer, metal scissors, a knife and a plumb line. - In order not to spoil the panels, and install them efficiently, it is necessary to observe a certain technique of their fastening to the frame. Hammer nails in the direction from the middle to the edges of the panel, strictly in the middle of the oval hole.

- It’s not worth hammering a nail to the end, the panel should move a little, but not hang out. If there are no holes for fasteners on the panel, do not try to hammer a nail into its case.

It is better to use a punch, and make holes along the edge.

When cutting a spotlight in size, it must be remembered that the details overlap, in two centimeters. When inserting a spotlight between the mounting strips, it is necessary to leave a gap of 0.5 cm.

Subject to these simple rules, the surface will be reliable and even.

I recommend using any color of PVC panels except white. White looks rather poor and dirt is visible on white, which will form sooner or later.