How to choose a manual spray gun

Painting with a spray gun allows you to get a perfectly flat surface after painting, with minimal time. The manual spray gun as a part has a pump and fishing rods and is used for finishing any surfaces with a chalk-and-chalk solution. How the manual spray guns SO-20V are arranged and the principle of their operation will tell the article.

The content of the article

The principle of operation of a manual spray gun

The work of a manual spray gun is based on the principle of operation of pump compression chambers, which are used for mechanical spraying of low viscosity of such colorful compositions as:

- Cretaceous.

- Water-calcareous.

- Water-glue.

They are used for small volumes of paint work and for spraying solutions:

- Fire retardant.

- For wetting.

- Gluing.

- Washing.

The design of the displacer determines the type of spray guns.

They may be:

- Piston: single or double action. Their design differs slightly.

- F-stop.

The composition of the manual spray gun includes:

- Base including two valves:

- suction;

- injection.

- Pressure hose.

- Convenient fishing rod.

- Rubber sleeve with a suction filter inserted in it.

- Removable cover.

- Pump.

To ensure reliable operation of the unit, its design must comply with some points:

- Light weight, while the center of gravity should be placed so that when working, the painter is not very tired.

- The spray head must have many sizes.: with different diameters of the nozzle hole.

- The main elements of the spray gun should be coated with anti-corrosion properties and have high resistance to wear.

Tip: Manual spray gun should not be used for a large amount of work.

Manual spray guns СО-20В in their design have:

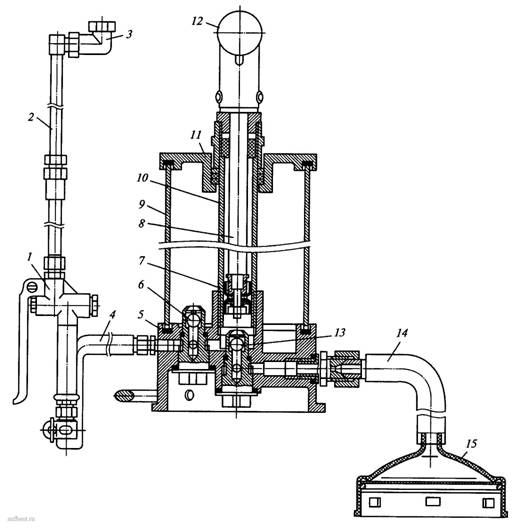

The photo shows a manual spray gun SO-20V piston type single-cylinder single action.

In its composition:

- Cylinder-shaped housing.

- Plunger pump.

- Suction and pressure hoses.

- Cleaning filter.

- Fishing rod with nozzle.

Wherein:

- The pump is placed in a sealed housing pos. 9, closed by a cover, pos. 11 on the one hand and the base, pos. 5 on the other.

- The composition of the cylinder, pos. 10 includes:

- stock, pos. 8;

- plunger, pos. 7;

- handles, pos. 12;

- suction valve, pos 13;

- discharge valve, pos. 6.

- When the stem rises, the suction valve opens and the paint solution is sucked in.

- When the stem lowers, valve 13 closes.

- The paint enters the tank through the discharge valve 6.

- On the sleeve 14, through the filter 15, which is attached to the base 5, the composition is absorbed.

- On the pressure sleeve 4 from the reservoir, the composition is fed to the fishing rod 2, on which an overhead crane 1 is installed.

- The convenience of the fishing rod is ensured by its collapsible design, consisting of two parts, which allows you to change its length.

- Nozzle pos. 3 is rotary, this ensures that the torch is located at a right angle to the surface to be painted.

Tip: To improve the sealing of the valves, before starting work, the spray gun should be filled with a small amount of solution, approximately 0.5 liters, pumping it with a pump.

- The filter is removed from the composition.

- Up to 20 double strokes of the rod are made, which fill the airbrush with air.

- The end of the suction hose with a filter is lowered into a vessel with paint and pumped to the desired pressure.

- To avoid splashing paint, the stem should rise smoothly. When working, avoid excessive pressure on the cylinder. When it decreases in the cylinder, the pressure should be raised, otherwise the paint will be applied too thick.

Tip: After completing work, the spray gun must be disassembled, and all its elements thoroughly cleaned.

How to care for a spray gun

For the long life of the manual sprayer, you must constantly do it yourself with your own hands, which will help to identify possible problems.

Checks can be:

- Shifts. They include washing and inspection of the device, which are performed after its use.

- Periodic. Run once every six months to detect malfunctions.

The algorithm of work is as follows:

- A visual inspection of the apparatus is carried out to identify possible breakdowns.

- All problems found during inspection are fixed.

- The gaskets are checked and, if necessary, changed.

- The quality of the apparatus is checked.

The instruction indicates that before painting the surface must be cleaned from grease and dirt. To do this, it is sanded with abrasive material, all dents and scratches are primed. A new coating layer is applied only after the previous one dries.

Tip: Before using the hand-held spray gun, it should be checked for proper operation and adjusted if necessary.

The principle by which the CROS-1 manual airbrush works, its features and scope, shows the video in detail.

Some rules for the smooth operation of the spray gun

To increase the service life of the device and its uninterrupted operation, it is necessary:

- Before using old paint, it must be filtered to determine its viscosity. If necessary, the composition should be diluted to the required density.

- The correct dose of the paint mixture should be used.

- Before use, check valve and nozzle wear.

- When applying latex paint, when the acrylic content in the mixture is above 20%, a lubricant is required.

Regardless of the type of spray gun, the surface after painting turns out to be of better quality and less time is required for work, while the cost of performing operations also decreases.