Porcelain cladding: finish features

Porcelain stoneware has been used for many years. For all this time, he has established himself as a very strong and reliable material.

The material is used for interior and exterior decoration.

The content of the article

Properties and characteristics of ceramic granite

Where did the name porcelain come from? Everything is due to the fact that porcelain stoneware is made for facing from two or three grades of clay dough with the addition of feldspar, which is involved in the formation of granite.

Manufacturing Features:

- The process of manufacturing porcelain stoneware is characterized by the use of high temperatures, under the influence of which the clay dough is pressed.

- Then, the material is fired and, after application of a certain design to its surface, re-firing is carried out.

Note. For this reason, facing porcelain tile has excellent strength and wear resistance.

In addition to the above characteristics, the properties include:

- Moisture resistance, an excellent indicator for interior decorating, which is often subjected to frequent cleaning, but also for exterior cladding, which should withstand climatic and weather conditions.

- Practicality, facing made of ceramic granite is quite simple to perform.

- Durability, the material has virtually no limitative period of use.

- Wear resistance. Despite the many diverse effects on the surface, the appearance of ceramic granite throughout the life of the product does not lose its original attractiveness.

- Frost resistance and resistance to high temperature conditions. In this case, neither the surface nor the structure of the material is deformed.

Note. It is worth adding that the ceramic granite cladding is not exposed to direct fire, and does not deform its structure.

Porcelain tile is quite heavy in weight, but it all depends on how large it will be.

The size of facing porcelain tile can be:

- 10x10 cm.

- 20x30 cm.

- 30x30 cm.

- 60x30 cm.

- 90x90 cm.

Additional characteristics:

- Porcelain cladding, whose thickness can reach 7-10 cm, looks not only original, but also quite massive.

- Looking at the properties and characteristics of a material such as porcelain stoneware, its price will seem rather low, although it is several times higher than the cost of a simple ceramic tile.

Porcelain stoneware

Porcelain cladding may have surfaces:

- Polished.

- Matte.

- Semi-polished.

- Glazed.

- Waxed.

- Rectified.

Let's consider in more detail:

- There are a variety of imitations of brick or masonry, wood and other natural materials.

- The polished surface of the material is achieved by cutting off the upper layer of the material and further watering with special equipment. This species is very similar in appearance to natural agglomerate.

Tip. This type of porcelain stoneware is not recommended for laying on the floor, as it is rather slippery.

- There is another drawback of the polished surface - it requires constant careful care, as it is subject to physical and mechanical stress.Immediately after its installation is completed, you need to walk along the surface with an acid-containing agent.

Tip. When using polished porcelain stoneware, it is recommended to apply protective mastic after cleaning.

- The cheapest and most practical at the moment is porcelain tile, which has a matte surface. She in the process of manufacturing the material is not exposed to any mechanical and physical influences.

For this reason, this species is often used in decorating. - Semi-polished ceramic granite is obtained by partial cutting of the upper layer of the material and its further partial polishing. After manufacturing, the material has a unique surface, which is distinguished by its originality, since it contains elements of gloss and roughness.

- The glazed surface of ceramic granite is similar in its production method to ceramic tiles. It is obtained by applying industrial glaze to the material and then firing it in one go.

Tip. In places with high traffic it is not worth using this type of porcelain stoneware, as it may lose its luster over time (the surface is worn down).

- The waxed surface differs from others in that it does not have a pronounced gloss and gloss, but has high practicality. This effect is achieved by applying mineral crystals to the surface of the material, which are fired together with ceramic granite.

- The rectified surface of ceramic granite is the most refined and is characterized by the fact that after the installation of the material practically no joints will be visible. In this case, the granite is facing, the dimensions are the same, since it is available in only one series.

All corners and other elements of the tile are in the same plane and complement each other.

Note. There are many more elements of ceramic granite that have mixed surfaces and are used to decorate the room and create a variety of panels or wall paintings.

Where can I install porcelain stoneware

Examples of ceramic granite cladding are quite diverse.

You can mount the material on any surface:

- Stone.

- Foam concrete.

- Brick.

- Wooden.

Nuances in installation work:

- Facing foam concrete with porcelain tiles does not differ from the finish of a simple brick surface.

- But in the installation of the material on a wooden surface there are some nuances, since it is often uneven due to the fact that a rounded beam is used.

Facing with ceramic granite can be on:

- The walls of the building.

- Socle (seePorcelain stoneware facing: choose material).

- The corners of the house.

So:

- This applies to outdoor work, but in interior finishes porcelain stoneware can be used on any surface: floor, walls, ceiling.

- Quite often they use it for facing fireplace portals with the addition of other decorative elements.

Mounting methods for ceramic granite

How to veneer with granite?

There are two methods that are quite widely used for the installation of this material:

- Special adhesive solution.

- Metal carcass.

So:

- These porcelain stoneware cladding systems differ both in their technology and in the materials used in it.

Tip. It is not necessary to resort to the help of specialists in the installation of porcelain stoneware. Both that and that technology are quite simple and to do everything really with their own hands.

If ordinary porcelain tiles are mounted on the adhesive solution, then on the metal frame - facade.

Installation of porcelain tile on glue or concrete mortar

Facing the surfaces with porcelain stoneware is carried out with special glue or concrete mortar only if the surface is even.This is due to the fact that the back side of the material also has a flat surface.

What you need to provide:

- There is a special glue for such work.

- On its packaging instructions. According to it, the powder mixture is poured into the container and a certain amount of water is gradually added to it.

- Everything is mixed with a construction mixer.

Tip. The adhesive mixture for facing with porcelain stoneware should have the consistency of dense plaster (“thick sour cream”).

With concrete mortar, everything is a little more complicated, since it needs to be prepared from:

- Sand.

- Water.

- Cement.

- Proportions: 1 standard bucket of cement for 3 similar with sand.

- Everything is also mixed with a construction mixer.

Tip. For mixing a concrete solution, it is best to use a concrete mixer, which will save time and effort.

To install ceramic granite you will need:

- Spatula.

- Mortar or glue.

- Building level.

- Cruciform lighthouses.

- Decorative putty if necessary.

The whole principle of work is very similar to the installation of simple ceramic tiles and there is nothing complicated in it.

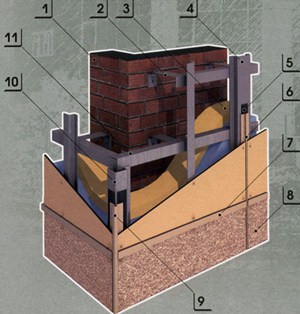

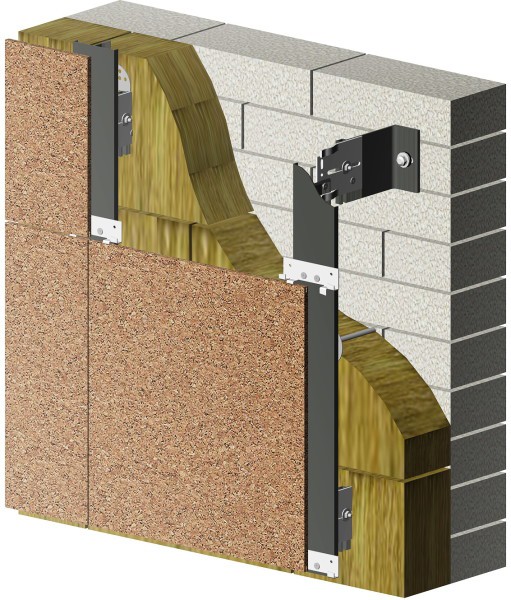

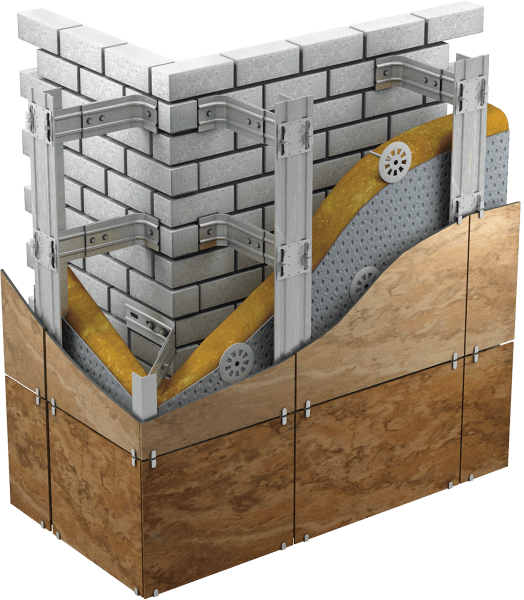

Mounting ceramic granite on a metal frame

This system for ceramic granite cladding is used when the weight and size of the material is large. Another advantage will be ventilation gaps in the finishing process, which contribute to good air exchange of the structure.

Initially, a heater is mounted on the surface, for this it is used:

- Styrofoam.

- Styrofoam.

- Polyurethane foam.

- Mineral wool - in rare cases, since over time it can lose its properties and characteristics from excessive moisture.

Work:

- Using metal profiles and various brackets, fasteners, a metal frame is made for facing with porcelain stoneware.

- For mounting the material on its surface there are also special fasteners, which provide not only a strong and reliable fastening of ceramic granite tiles, but also a uniform distance between all elements of decoration.

Tip. The most important thing is that the knots of porcelain stoneware cladding should be thought out initially, since further finishing will be repelled from them. They are the main connecting link of the entire cladding.

- In such works, a tile cutter with a laser cut may be needed, since all roughnesses and cutting defects of the material will be immediately visible on the surface.

- After complete installation of ceramic granite on a metal frame, you can use a decorative putty, which is intended for outdoor finishing work. Under the influence of climatic and weather phenomena, it does not lose its properties and reliably smooths all the joints and seams of decoration elements.

The video shows the process of installing ceramic granite on a wall surface using a metal frame.