Plastic sheets for walls: their types and installation rules

Plastic sheet for wall decoration are used quite often. This is essentially a universal material that is suitable for both residential and industrial premises. These products are of several types, and they differ in their characteristics.

Today we will consider what plastic sheet panels are for walls, what is better to choose and their installation rules. Also in the video in this article and photo you can see the different types of finishes with this material and choose the most suitable.

The content of the article

Benefits

Plastic sheet panels for walls have a number of advantages that allow them to be used for many rooms. But this does not mean at all that there are no shortcomings.

Therefore, before buying, you need to study everything and only then make a decision:

- Decent appearance;

- Simple care. To remove dirt from the veneered panel, you should use ordinary detergent and water, but abrasives are strictly prohibited;

- Resistance to moisture and color retention from sunlight;

- Although the price of plastic is not large, but still it sometimes needs to be changed. This is not difficult and fast. After all, the panel is mounted in profiles and you just need to cut the desired size and replace;

- A huge palette of various colors and shades, with which you can realize almost any project, even the most unusual.

- Long service life.

- Resistance to abrasion, discoloration, mechanical stress.

- A variety of textures, textures and colors of products.

- Easy installation.

- Convenience of operation. It does not require special care, it is easily cleaned of contaminants.

- Installation on any surface is possible.

- It is allowed to use in rooms with high or low temperatures (baths, balconies, loggias, warehouses).

Plastic sheet panels for walls have a number of drawbacks to be reckoned with:

- Do not install them in places of direct sunlight, in this case they simply fade;

- They do not burn, but with direct exposure to fire, they emit harmful gases to human health.

Attention: You should never buy plastic panels for the walls of sheet not known manufacturers, give preference to proven. After all, not high-quality plastic can be quite harmful.

Varieties of plastic panels

Plastic panels are a relatively new material in the construction market.

It is used both for internal and external wall decoration:

PVC panels for interior use | Plastic sheets for internal walls have a thinner profile. They do not always tolerate temperature extremes. They are susceptible to mechanical stress. |

Front panels PVC | These are more rigid elements that have a thick profile and perfectly tolerate temperature differences and high humidity. During the insulation they are not squeezed out by the insulation. |

The finished product is made by heating polyvinyl chloride (PVC), molding with its subsequent cutting. Usually panels produce two groups.

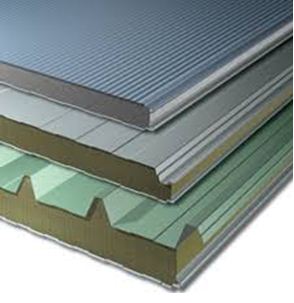

PVC sectional panels | With standard thicknesses: 5 mm, 8-10 mm. They consist of two sheets of plastic, fastened through a certain step by longitudinal ribs. |

PVC sheet panels | The width of the product is from 20 to 37 cm, the height is 260, 270 and 300 cm, the thickness is 0.4 mm. |

The main difference between the first group and the second is the installation method. For sheet material, it consists in gluing onto a previously prepared surface of the sheets.

Process is like wallpapering the walls. The material is easily rolled up, cut with a clerical knife or scissors, convenient for decorating openings, niches, arches.

When decorating with sectional elements, you must first complete the frame, and then install the structure.

The types of PVC panels include:

- Vinyl wall paneling. It is carried out both in sheet (up to 120 cm wide and up to 245 cm high) and sectional versions (10x300 cm). In appearance it resembles boards with a groove-ridge connection. Most often used for exterior decoration of houses;

- Panels (rectangular or square tiles 30x30; 30x60; 90x90 cm).

PVC products differ in the manufacturing technology of the upper layer:

- A two-component composition is applied to the front part, fixing the protective film. This process is called lamination. Thanks to the rich selection of textures, you can imitate various materials (stone, leather, fabric, wood). The material will stop more resistant to humidity and temperature factors.

- Using two-stage printing, an image is applied to the surface of the panel, after which it is fixed with an antistatic varnish. This method is called offset printing. It is used to create an imitation of marble pattern. Panels of this kind are resistant to mechanical stress and household chemicals.

- Under the influence of high temperatures, a prepared film is applied to the prepared panel, with the image already applied. This method is called thermal printing. Materials do not require further additional coating. And the main feature is the resistance to discoloration as a result of ultraviolet radiation. Products have a characteristic rich color palette.

The use of plastic panels

Accessibility, results and convenience are characteristic features of the product. Excellent work results and installation speed make this type of material more popular. It is suitable for many room decoration options. Due to their composition, plastic panels have advantages over other materials for internal work.

Before buying a product, you need to decide which room you are purchasing the material in, how much it will be needed, and be sure to check the quality of the lot.

Balcony

Products should be selected moisture resistant, resistant to sudden changes in temperature, durable, with high-quality color (not fading).

- For small narrow rooms, light-colored panels with a glossy finish are best suited.

- If necessary balcony insulation You can additionally use the space between the crate and the panel to install heat-insulating material.

- Thanks to the development of technology, it has become possible to produce products with a surface similar to wood, marble, which makes it relevant if necessary to withstand a single stylistic solution.

Bathroom

Preference is given primarily to moisture-resistant materials without protruding elements, resistant to temperature extremes and high humidity.

The ability to use different shades (from light to dark), ease of fastening - makes the panel one of the most used. With their help, you can hide the irregularities of the ceiling, sewer, water pipes, hem the niches and ducts (seeCovering the bath with plastic panels: do it right).

Living rooms (living room, bedroom, children's room)

One of the important qualities is the aesthetic appearance. Although it is worth saying that this product is not often used in residential premises. But some interior details are still being implemented.

With the help of a competent installation of light and the selection of textures, you can pick up amazing combinations.Smooth, seamless, stone, wood panels will complement the design.

Combining the original pattern and a practical surface, the material becomes an alternative to the usual wallpaper. The panels are easy to clean, which is especially true in children's rooms (dust, stains, drawings).

Kitchen

Wear resistance, moisture resistance - the main characteristics that the buyer should pay attention to. This zone requires the highest quality material, which is easy to care for.

To decorate the room, it is best to choose pastel color panels (seeDecorating the kitchen with plastic panels or a new boom) In this case, the mark from greasy stains will not be noticeable (in the event that quality material is not of good quality).

The corridor

It is recommended to use moisture resistant panels without decorative elements. This will provide easy care and ease of use. Often when wall cladding, two types of panels are used: dark and light. This is done for reasons of practicality.

Offices

A huge variety, characteristics, practicality made the material common for decoration of office premises. The main advantage is affordable cost. A wide selection of products allows you to use them in the design of any type of premises, betraying originality and sophistication.

Basements and warehouses

Fire safety, low cost - characteristics due to which steel panels are widely used in interior decoration of warehouses. The material allows sheathing large surfaces and is easy to operate. The ability to work in conditions of high humidity and a sharp temperature drop makes it one of the best.

Plastic panels must not be used in places intended for the evacuation of people. When ignited, they release toxic substances hazardous to human health.

Plastic sheet for wall decoration offers a wide range of finishing options. These are various combinations with other materials and simply interesting solutions. The gallery presents various finishes with this material.

It is possible with the help of sheet panels and the desired pattern to identify areas in the room, even if it is not large

Siding is often used in facade cladding (seeFacing with siding facade: the whole cycle of work) It not only looks great, but also allows you to immediately make the insulation of the room.

The combination of different panel colors allows you to make original drawings and improve the interior of the room.

By placing the panels vertically, you can always visually raise the ceilings and increase the volume of the room.

The use of various types of panels will highlight different planes in the room.

For large rooms, contrasting colors are often used and this can just add volume, but can also be quite attractive.

Panel Installation

Plastic sheet for walls will repeat the contour of the base plane and therefore it should be perfect. After that, high-quality installation should be carried out, only then you will get an attractive coating. Let's talk about installation rules now.

Crate

Plastic sheet for walls attached to the crate. In rare cases, it can simply be glued to the walls, but for this they should be perfectly even. Therefore, most often this is done precisely on the crate.

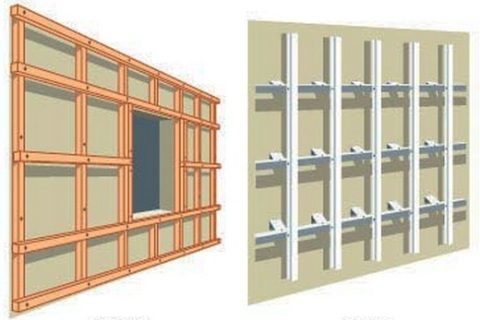

It can be made of metal and wood:

Metal crate | The mounting structure can be made of S-shaped profiles. Depending on the material of the walls, the installation is carried out using building screws and “crackers”, dowels, nails.

|

Wooden crate | This material is more convenient at work and you can do it yourself without any problems. Especially if it's hard to reach places. Pretty simple to handle

|

Plastic mounting

Installation instructions are not complicated. Installation of PVC panels produce on a pre-prepared structure of rails or bars - crate or on a prepared surface of the walls.

Wall decoration with PVC panels is carried out in the following order:

- On the prepared base, install the crate;

- Mount the start, end and guide profiles;

- The initial panel is installed with a narrow shelf towards the first profile;

- The panel is fixed with the help of a bracket device on the crate, after which the remaining products are installed in the row except for the last;

- The last element of the row is shortened from the side of the wide shelf with a small gap, moving along the board;

- With effort, the final element is inserted, carefully bending the shelf with a spatula and attaching it to the crate.

Designing a modern interior using plastic panels is a painstaking work that requires time and exact adherence to technology to achieve a high-quality result. A variant of the use of such material is especially popular for finishing balconies and bathrooms.

A variety of color range, prints, drawings and textures allows you to withstand, and the characteristics meet the most capricious operating conditions. Observing the simple rules for installing panels, you can get the desired result.

Some recommendations when using PVC panels:

- It is more practical to install panels in rooms with a wet operating mode (bathroom), sudden changes in temperature (balconies), subject to contamination (hallway).

- When used in living rooms, the need for normal air circulation should be considered. This is done by natural ventilation or by installing an air conditioner. Especially relevant when performing lining with a seamless material.

- It should not be installed in the children's room, in the kitchen (especially in the cooking area), places of sports.

- During installation, it is worth handling the instrument carefully so as not to damage the material.

- The finish profile should always be used. It is an important element without which the work will look rude and careless.

- Before choosing panels and profiles, it is better to give preference to proven brands (low-quality materials can crack, bend, jam at the joints).

- The crate is best performed with maximum accuracy. The evenness and convenience of work directly depends on how you installed and secured the frame.

You can install sheet plastic panels for walls completely independently. The most important thing is not to rush and apply quality materials.