How to paint a brick oven: we select the material

How to paint a brick stove in a house? A Russian brick stove folded according to the rules gives off half the heat it gives off to the room. But its amount depends on the material covering its surface. In this case, the rough surface of the heat gives off more than a smooth one.

In the villages, Russian stoves have long been painted with lime, and the owners of rich houses decorated the stove with tiles, turning designs into real works of art. The article will tell you how to paint a brick stove?

The content of the article

Why paint brick stoves

There are several reasons for painting brick ovens:

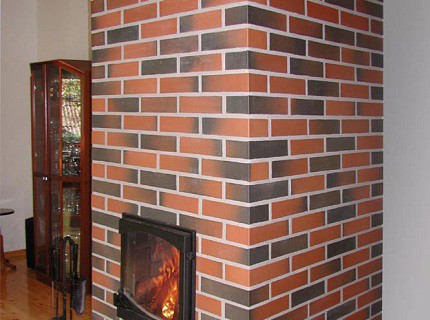

- Craving owners for aesthetics. If before the stove in the village house was the only device for heating, now fireplaces and stoves serve as interior elements that must be harmoniously entered into the home.

- Furnish the surface of the stove paints prevents the appearance in bricks, and then the increase in cracks, the surface makes it smooth.

- After painting, the heat transfer to the room increases.

Tip: It should be borne in mind that the operating mode of the stove in the country or in the house is very different from the stove in the bath. The coating technology will be different: materials for processing the stove in the bath may not be suitable for the stove in the country.

For coloring furnaces, materials such as:

- Natural drying oil. The coating does not change the color of the brick, but changes its hue to a darker one. It can be used to cover ovens in a bathhouse.

Tip: When using natural drying oil for a brick furnace after its kindling, you can only operate for a few hours. Do not experiment in a house with drying oil: different combustion modes in the furnace can prevent drying oil from drying out.

- Organosilicon enamels. Its technical characteristics:

- excellent adhesion with all materials;

- high strength;

- moisture resistance;

- durability.

- ability to withstand up to 200 cycles of change of positive and negative temperatures.

The disadvantage of silicon organic enamels is a small selection of colors.

- Varnish PF 283. When using varnish, it is mixed with turpentine in equal proportions, which increases the strength characteristics of the material. After drying, a transparent high-quality glossy layer forms on the furnace surface.

The peculiarity of the use of varnish is the ability to add dry gouache, which will allow you to get the paint material of the desired color.

- Heat-resistant paints (see Heat-insulating paint: material features). This is almost perfect. Its advantages:

- huge selection of colors;

- withstand temperatures up to 600ºС;

- such paint protects the brick oven in the house from oxidation;

- increased strength and endurance;

- ease of application, without first priming the surface;

- keeps operational qualities till 10 years.

When operating the furnace, efflorescence on the brick may appear. This comes from exposure to high temperatures, when moisture along with salt begins to be displaced from the kiln brick. Heat-resistant paints will not lose their characteristics from this.

Lack of paint:

- the presence of an aggressive chemical composition;

- bad smell;

- dries for a long time;

- when working, care must be taken due to the presence of toxic substances in the mixture.

How to make paint materials for a brick stove yourself

To paint a brick stove in a house is simple and inexpensive.To do this, use lime or chalk, their price is the lowest. Such materials are abundant in any hardware store, and only water will be needed to breed them.

The difference between the solutions of lime and chalk is as follows:

- After staining with the chalk solution of the first layer, you need to wait for it to completely dry.

- If you cover the oven with a solution of lime, all subsequent layers are applied immediately.

To paint a brick oven, you need to do the right solution yourself:

- One kilogram of chalk or lime.

- Water - 1.5 liters.

Tip: After applying such a composition to the furnace, the strength characteristics of the coating are not of very high quality. The surface will smear clothes and begin to crumble. To avoid this, you need to use table salt. For 2 kilograms of paint, 0.3 kilograms of salt is added. The result is excellent strength characteristics.

Instead of salt, you can use carpentry glue, 0.1 liters of glue per 10 liters of paint is enough. Such formulations may have a yellowish tint. To achieve a classic white color, you need to add 20 milliliters of ordinary blue to the solution. The color additive should be used to obtain the desired color.

Tip: When applying the additive, the instructions for its use must be followed in order to obtain the desired color.

How to make natural varnish for the oven

Our ancestors used ordinary chicken egg to paint the varnishes when staining the ovens.

This will require:

- Squirrels of eggs.

- Milk.

- Brick dust remaining after fitting and trimming bricks during the laying of the furnace.

After conducting the experiments, it was determined that the best composition is obtained with a ratio of egg whites and milk 1: 1. To finish a square meter of the surface of the oven, you need about 0.25 liters of milk and 8 proteins. The amount of brick dust is determined independently, it only affects the color characteristics of the varnish made from natural materials.

In the manufacture of the composition:

- Rubbed with red brick flour.

- Beat egg whites and milk are added until a thick consistency is formed.

- The mixture is mixed.

- The oven is painted with a new brush on a preheated surface.

- Coverage is obtained in even red. It has heat resistance and high abrasion resistance.

- The stove is covered with drying oil, then the dark red surface is dull.

- To obtain shine, a special synthetic varnish is used.

After applying such varnish to the furnace surface and drying it, the brickwork is not strong, but it will stain. To eliminate this drawback, you can apply one layer of a solution made from pure egg protein to the stove. The disadvantage of this coating is that it emits the aroma of baked milk in the room when the stove is in use.

How to color the stove

Tools for painting brick ovens:

- Metal spatula for surface preparation and for puttying.

- Brush to brush away the remnants of the former finish.

- Small special capacity.

- Soft brush.

After choosing what to paint the red brick stove in the house, you can perform preparatory work.

For this:

- The stove surface is carefully leveled with plaster (see How to plaster a brick stove with your own hands).

- In a rough way, protruding fragments of a clay mortar located between bricks are scraped off with a special scraper.

- Using a sandpaper, the surface is prepared to improve the adhesion of paint and kiln bricks.

Tip: Sometimes the surface should be treated with a heat-resistant primer, which will not hurt, but it should be used without caustic additives so that they do not stand out at high temperatures. In the absence of a primer, the surface of the furnace before applying paint should be treated with water.

- The paint is applied in two or three thin layers, with a new brush or roller. The surface brush gives texture, and the roller distributes the paint more evenly, which gives the surface smoothness.

- If desired, on a dried coating layer, patterns are applied mechanically.

Today, homeowners are very interested in interiors decorated in the following styles:

- Country.

- Chalet.

- Shabby chic.

Their distinctive feature is the naturalization of various elements and decorative details. In such interiors, the best possible way, a bright and stylish addition is a Russian brick stove or fireplace. To do this, they can simply be painted with transparent paint. How to prepare the surface, and then paint them will show the video in this article.