The sequence of laying the frame wall: we follow the rules of technology

The construction of concrete frame walls is not a very complicated process of building a private house or cottage. The main thing is that all the elements are well fixed, and the wooden parts are protected from moisture. With good care, the frame house can be used for more than 50 years. The article will tell you how the walls of frame panel buildings are erected.

The content of the article

Features of frame houses

Despite the relatively recent emergence of the technology by which such houses are built, it gained quite a lot of popularity among developers, successfully competing with other building technologies. The basis of a monolithic frame house is a frame made without the use of welding.

Its main elements:

- Vertical columns.

- Communication.

This is a single, rigid system that serves as a support for the construction of the entire structure. Its walls are not load-bearing, but serves as a fence, which makes it possible to use not very dense and durable material with improved thermal insulation properties for their manufacture.

The features of this do-it-yourself house building method are:

- The ability to make any layout - there are no restrictions in the location of the walls.

- Any wall after construction can be removed without violating the strength of the structure.

- The partition wall can be installed anywhere.

- Safety of operation of such buildings. Even when the walls are destroyed by explosion, the monolithic frame remains intact.

Tip: Monolithic frame construction of your home should be built in earthquake-prone areas and in places with the threat of flooding.

- There are no butt joints in the walls of monolithic buildings, which helps to reduce heat loss during the operation of structures.

- The shrinkage of the base of the frame house occurs evenly around the entire perimeter.

- Frame elements are often manufactured at the factory.and the required amount of materials and all components goes directly to the place of assembly of the building, and the construction is carried out without waste.

- High speed of construction. Frame assembly can be done in about three weeks.

- Pretty quickly the frame is filled with walls and a ceiling is built.

- Light weight structure.

Disadvantages of monolithic frame houses:

- The complexity of the design. Even when designing, it is necessary to provide for the device of all communications in the house. If this is not done, laying them can cause some difficulties.

- It is difficult to carry out concrete work. To install the formwork and conduct concrete pouring, it will take considerable effort and a lot of time.

- Concrete walls have low heat and sound insulation, which requires an additional thermal insulation device at home (see. How to properly insulate the walls with your own hands).

Tip: To solve the problem with thermal insulation, it is necessary to arrange a fixed formwork. This will make it possible to lower the heat loss, and to make the decoration and cladding of the house efficiently.

What materials are used for the device frame

In the construction of the frame are used:

- Reinforced concrete. In this case:

- you will need to use special equipment when installing the structure;

- transportation costs increase;

- more costs will be needed when building the foundation.

But then the life of such buildings reaches 100 years, gaining great strength every year.

- Metallic profile.

- Wooden beam (cm. Timber house interior decoration: design ideas).

When using the last two materials, the price of a frame-monolithic house will be less. In most cases, cement-bonded slabs and other plate materials are used for cladding the frame.

Between the slabs the space is filled with lightweight concrete, which can be:

- Foam concrete.

- Foam concrete.

Walls of frame monolithic buildings can be:

- Brick.

- Of the blocks.

- From stoves, which many prefer. In this case, the thermal and sound insulation of the walls of the building is improved. In addition, the plates serve as an excellent basis for subsequent finishing.

Technology for the construction of a monolithic frame house

Modern technology for the construction of a monolithic frame house allows you to erect buildings of different sizes and heights. For high-quality construction, it is necessary to correctly carry out the construction of formwork and the preparation of concrete.

These components are the basis of a monolithic frame structure. Poor quality of formwork and concrete reduces the strength and operational life of the structure.

The instruction for the construction of a monolithic house offers the following stages of work:

- Foundation device.

- Mounting the frame from the reinforcement.

- Installation of formwork for the base.

- Pouring concrete.

- Removing formwork.

- Finishing work.

Of great importance in the construction of walls is their proper reinforcement.

To do this, you can use:

- Armature.

- Reinforcing mesh.

When using reinforcement with a diameter of 6 - 8 or more millimeters, the structure receives high strength.

The fittings are installed:

- Horizontally.

- Vertically.

Particular attention when reinforcing walls should be given to corner structures.

Tip: The reinforcement must be firmly fixed to prevent the structure from buckling after pouring concrete.

Additional frame structures should be equipped with openings in monolithic walls to evenly distribute the load.

Advantages that the technology of manufacturing a frame wall from OSB plates has:

- OSB is wood with improved strength and flexibility characteristics. The material is easily processed, which allows you to create quite complex architectural structures.

- The uniformity of the structure of such plates is a guarantee of the absence of voids in the panels of the frame house.

- The OSB plate along the entire perimeter has a homogeneous structure and density, which is 2.5 times higher than this indicator for a chipboard plate.

- Moisture resistance of the material. When the plate is immersed for 24 hours in water, it will swell by 17%, while the strength characteristics practically do not change.

- The fastening of OSB plates can be done with any fasteners.

- OSB plates do not require additional sound insulation.

- The cost of such plates is the lowest.

How to insulate reinforced concrete facades

Tip: Thermal insulation of concrete buildings should be made only from the outside. When warming the house from the inside, between the surfaces of the wall and the insulation, condensation will form, which contributes to the formation of mold.

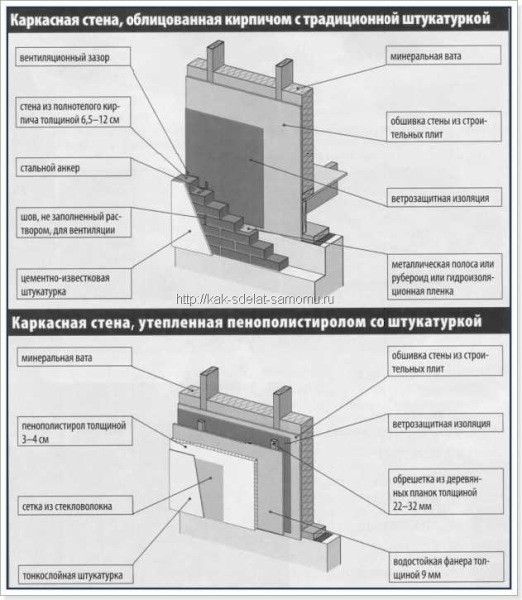

Before finishing the frame wall outside the house, the technology of its thermal insulation is selected.

The process can be performed:

- Installation of a wet facade.

- Polyurethane foam spraying (see Liquid thermal insulation for walls: features of use).

- Plastering the surface with a special heat-insulating mixture.

When conducting a "wet facade" you can use:

- Styrofoam.

- Thick mineral wool.

Both of these materials significantly increase the thermal insulation of the house.

However, there are some differences between them:

- Different cost. Polyfoam will cost much cheaper.

- The vapor permeability of expanded polystyrene is lower.

- The installation of the foam is easier because of the high density it is easier to fix on the wall and perform subsequent surface treatment, as in the photo.

The “wet facade” technology used for reinforced concrete structures has undeniable advantages over other methods of thermal insulation.

These include:

- Low cost with a good effect on the insulation of the house.

- Unique design solutions allow you to create almost any option without a large investment of money.

- Without much work, you can change the wall decoration by painting it with a different color or using decorative plaster.

- Installation of the material is carried out without the use of metal fasteners, which avoids the formation of "cold bridges".

When spraying polyurethane foam, you will need to purchase special equipment. Warming is done by mixing two chemical components applied to the wall with the help of a compressor; according to the principle of operation, it resembles a conventional airbrush. It takes just a few seconds for the material to harden and create a uniform layer that will not allow air and moisture to pass through.

The advantage of the method:

- Lack of fixing elements.

- Not afraid of moisture.

- Fast gluing to the wall.

Disadvantage: Under the influence of the sun, the polyurethane foam will begin to collapse very quickly, which requires the use of facing material.

For applying facade plaster, more efforts will be required when finishing a reinforced concrete wall.

This is due to the lack of large roughness on the surface, which creates mounting seams on brickwork.

Therefore, the assembly scheme of the frame wall of reinforced concrete by applying decorative plaster is different from the rest. In this case, you need to use a reinforcing mesh 40x40.

In addition, you need to purchase:

- Antiseptic fluid.

- Roller or spray.

- Different sizes spatulas.

- Primer

- Hammer drill.

- The expansion bolt shield 6х40.

- Stucco with thermal insulation effect.

Work procedure:

- Pre-prepared wall.

- An abrasive mesh is attached to the surface with dowels.

- The mixture is diluted to a uniform consistency.

- The solution is applied with a spatula to the wall and evenly distributed from the bottom up to the surface with a thickness of one layer up to 8 millimeters.

- The total number of layers is at least three. Each subsequent is applied after the previous has dried.

Tip: To calculate how thick the frame wall should be, you should read the coefficient of resistance to heat loss or the coefficient of thermal conductivity.

Compliance with the correct technology for the construction of the frame structure will allow you to get a beautiful and comfortable building with a long service life. And how to do it better will tell the video in this article.