Epoxy Putty

Epoxy putty is a type of putty that is used to restore the building foundation before finishing. Professionals consider the product the best among similar products. The only drawback of the composition is the high price.

The content of the article

Characteristics

Epoxy putty has the following characteristics:

• does not exude an unpleasant odor;

• frost resistance;

• does not shrink;

• resistance to chemical components and damage;

• long service life;

• it is well smoothed out by an emery paper;

• facilitates finishing painting.

Features

Product features are that the composition dries slowly, so when preparing the solution, you can not rush. 60 minutes after puttying, polymerization begins. After 6 hours, the composition freezes, but professional craftsmen recommend waiting a few more hours before moving on to the next stage of work. Two hours after the putty hardens, the surface is cleaned and covered with paint. Moreover, in the interval between grinding and painting, the primer is not used. The characteristics of the putty allow you to do without priming. The main thing is to clean the building base from dust before painting.

Unprofessional craftsmen who do the finishing themselves do sometimes encounter the problem of hardening of the product during application. This is due to the fact that without repair skills it is difficult to quickly apply the tool. If such a nuisance occurs and the composition hardens, do not dilute it with a solvent. Such manipulation will lead to the loss of product properties. The best solution is to heat the product up to 800 C. After this, the putty will become soft.

The composition of the putty

Another name for the product is two-component putty. The composition of the material includes:

• Epoxy resin. This component is a brown viscous substance. Resin is the main active ingredient, which determines the characteristics of the product.

• Fillers. The components are metal shavings or fiberglass. Such substances are responsible for the strength of the material after solidification and mask surface damage.

• Hardener. This tool provides the density of the product and solidification.

Application area

Epoxy composition is used in construction. The product is used to mask defects and to level surfaces indoors and outdoors. Epoxy putty also protects the surface from mold or mildew. Such compositions are also used in shipbuilding and in the repair of swimming equipment and automobiles.

Type of material for its intended purpose

For concrete pavement

Epoxy putty for concrete, in addition to the main components, includes cement and coarse sand. Such substances improve the adhesion of the composition and simplify the finish.

If there are cracks in the concrete, then professionals recommend that they be repaired with a tool that consists of epoxy and hardener. It is called epoxy glue. First, they fill the defect, and then level it on the surface. If the crack is significant, then the composition is mixed with sand or cement.

For wood

Wood is a moving material subject to compression and expansion under the influence of temperature and moisture. Therefore, only special products are used for puttying, which include putty with epoxy. The composition provides elasticity to the wood and does not shrink. After solidification of the material, the base is easily cleaned with sandpaper.

Hard putty with epoxy resin for wood is used in the following cases:

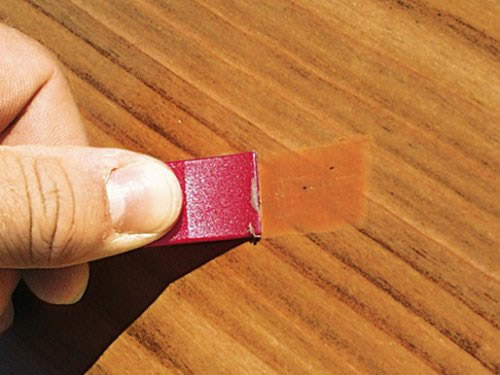

• to mask defects - small cracks and scratches (as in the photo below);

• for leveling the floor for further finishing;

• for windows, doors and furniture;

• to protect the surface from moisture and aggressive bacterial environment.

Epoxy putty can not be used on a wooden surface if a stain is used as a finish.

For plastic

Due to the adhesive properties of the composition with an epoxy resin is used for plastic. The tool masks defects on the material, so the product is used when repairing car parts and PVC pipes. The lack of putty is toxicity, therefore, the composition is recommended to be used only in protective equipment.

For metal

Epoxy based putty is used for metal. The composition is easy to apply and clean after hardening.

To ensure that the tool adheres to the building base, professionals recommend using sawdust of the material of which the surface is made as a filler.

Putty with epoxy resin is used to repair a car body. The composition smoothes the surface and also protects the material from corrosion. For cars, putty is used with aluminum powder.

Expense of funds

The consumption of the composition is 700 mg per 1 m2. In some cases, more may be required, in others less. It all depends on the density of the composition. If the solution is too thick, then the consumption of the product will increase, and if liquid, it will decrease.

Foundation preparation

To apply the composition, the surface does not need priming. It is enough that the material is clean. In addition, the construction base is recommended to get rid of oil and grease stains.

DIY cooking

Epoxy putty can be prepared independently. This will require:

• epoxy resin;

• hardener;

• filler.

The choice of the last component depends on the base on which the product will be applied:

• for wood it is advised to use gypsum, chalk or sawdust;

• cement, fiberglass and sand are suitable for concrete;

• for plastic, it is recommended to use colored pigment to mask the defect or fiberglass;

• for metal, aluminum powder or particles of another metal.

Combine the components, taking into account that the hardener should not exceed 3% in the product. Stir material and use for puttying.

Putty application

Putty application:

• take a wooden spatula and mix the product thoroughly;

• apply the composition with a spatula to the surface;

• stop work for 6 hours so that the composition freezes;

• apply a second coat of putty;

• take a break of 8 hours to dry the composition;

• Clean the surface, brush off the dust and apply the paint.

The video in this article shows the rules for using the tool.

Epoxy putty is a composition that is notable for its durability and long service life, therefore the product is popular with professional and non-professional masters.