How to plaster walls with cement mortar?

Cement plaster - a building material that is used in the decoration of rooms and facades of buildings as a rough or decorative coating. The tool is suitable for any construction site. The product is used for wall decoration outside the building, indoors, as well as in rooms with high humidity and for screeding. One of the main advantages of the product is its reasonable price. Material can be purchased ready-made, and fashionable to do it yourself. The main thing is to know how to make a cement mortar for plaster and to use the composition correctly.

The content of the article

Material Features

Cement-based plaster is popular with finishers. The increased demand for the material is explained by an acceptable cost, the possibility of use for facades and rooms with high humidity and for any construction grounds. However, the product also has drawbacks: it cracks after solidification and peels off the surface. To avoid this situation, it is recommended to observe some rules when applying the solution:

- apply the material only on a prepared building base;

- when mixing the solution, strictly adhere to the ratio of the mixture and water;

- apply the product carefully but quickly so that the material does not have time to set before the final surface treatment;

- use the material at a temperature of + 5- + 300WITH;

- after applying the solution, it is not recommended to accelerate the rate of solidification of the product, but to regularly moisten the construction base with water so that the material does not crack;

- when using any tool for plastering, the device should be regularly moistened with water to avoid sticking of the composition;

- after plastering the surface, it is recommended to clean the tools, otherwise the next time they are used, the devices will degrade the quality of the plaster.

Product Types

The main component of the product is cement. The composition is also supplemented with other binders - lime or clay. To improve the characteristics of the product, pumice, sand, gravel or slag is also added to the product. The material is classified according to the astringent components present in the composition:

- cement plaster - such a product is characterized by increased strength;

- cement-sand composition - is resistant to cracking after solidification;

- cement-lime remedy - prevents the occurrence of mold and fungus on a building base;

- cement-clay material - has refractoriness, therefore the product is used for plastering stoves and fireplaces.

The greatest demand is cement-sand material. This is due to the simplicity of preparation and use.

Necessary materials and tools

For plastering the surface with cement-sand mortar, the following materials and tools are required:

- plaster;

- primer;

- water;

- a roller, brush or spray for primer application;

- mortar trowel or plaster bucket;

- rule for leveling the solution;

- industrial grater and grater;

- set of spatulas;

- An industrial mixer or drill with a nozzle mixer, if plastering a large area is required, it is recommended to use a concrete mixer;

- guides;

- level;

- capacity for solution preparation;

- hammer.

If you plan to independently prepare a cement mortar for plaster, then instead of the finished composition take the following materials:

- quarry sand;

- cement grade M400 or M500;

- water.

Surface preparation

To prevent cracks on the surface after solidification of the material, it is recommended to carefully prepare the construction base.

Brickwork

A brick surface is prepared as follows:

- dismantle the old coating;

- excess cement mortar between bricks knock down with a hammer;

- the surface is tapped for unstable fragments, the defects are expanded, primed and filled with cement mortar;

- the surface is cleaned and degreased, and also treated with an antiseptic solution to prevent mold and mildew;

- metal elements are removed or treated with an anti-corrosion substance;

- two primer layers are applied to the surface and after each treatment a break is made for the composition to solidify.

Concrete base

A concrete base is prepared in the same way as brickwork. The work algorithm is identical.

Wood surface

A wooden building base is prepared in the same way as previous surfaces, but there is no need to examine the material for defects, and a special primer for wood is used for priming.

Surface reinforcement

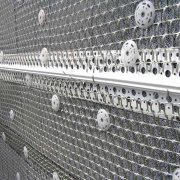

Surface reinforcement is performed to increase the strength of the cement mortar, increase the resistance to mechanical damage and to prevent cracking of the material after solidification. The mesh is used without fail for wooden building foundations and when applying plaster in a thick layer.

The metal product is fixed using self-tapping screws with wide caps. For this, dowels are fixed on the wall at a distance of 0.4 m from each other. The dowels are staggered. Next, the mesh is cut into pieces using scissors for metal. After that, the material is fixed on the surface in a direction from the bottom up. The mesh is pulled and fixed to the dowels using self-tapping screws. The sheets of the product are overlapped by 10 cm on each other.

Fiberglass nets are fixed directly to the solution. To do this, the material is applied to the wall, pressed to the plaster of the branch and carried out on the surface with a spatula, pressing the product into the composition.

Guide fixing

Lighthouses are installed on the walls vertically and parallel to each other. Guides help to evenly distribute the solution on the surface. The use of guides is especially true if the lay-up is done by a layman. Lighthouses fix this:

- 15-20 cm are indented from the edge of the wall, from the floor and the ceiling, and dots are put at the top and bottom that connect with a straight line - the wall performs this manipulation on the other side;

- marking is done on the surface of the building base at a distance less than the length of the rule;

- plaster mortar is fixed along the lines with small tubercles;

- beacons are applied to the material and the products are pressed into the composition.

Solution preparation

If we talk about how to prepare a cement mortar for plastering walls, then it all depends on what brand of material will be used. If product M400 is used, then 1 part of cement and 4 parts of sand are taken. For a product of the M500 brand, the proportions will be as follows: 1 part cement and 5 parts sand.

All components are placed in a clean container and the solution is kneaded with an industrial mixer or a drill with a mixer nozzle.The product is kneaded until a smooth, lump-free consistency is obtained.

If we talk about how to prepare a cement mortar for plaster from the finished dry mix, then the dry composition is placed in a dry container and water is added in the proportions indicated on the package. After that, the solution is kneaded to a uniform consistency using an industrial mixer or other similar tool.

The material is left for 5 minutes before ripening and is used as intended.

Plastering technique

To finish lasted for a long period, it is recommended to follow the rules for the use of cement mortar.

Material application

Instructions for applying the material:

- the surface is wetted with water - this manipulation improves the adhesion of the solution to the building base and prevents premature solidification of the material;

- with a ladle or trowel, they throw the solution on the track located between the beacons, from the bottom up - this procedure is carried out along the perimeter of the building base.

Solution leveling

Alignment of the solution is performed using the rule, as in the photo below. To do this, after applying and setting the material, the tool is pressed against two adjacent beacons at the bottom of the building base. Next, the guide is lifted up. The excess solution is removed with a spatula, and the resulting voids are filled with a cement composition. Such manipulation is performed on all tracks.

After setting, the beacons are dismantled. If this operation is not performed, then rust will appear on the finish over time. The guides are removed, and the resulting voids are filled with cement mortar with a spatula.

Surface cleaning

Surface scrubbing helps to get rid of stains left by a rule or a spatula and prepare the building base for decoration. Manipulation is performed after dismantling the beacons and setting the solution. The degree of readiness of the surface is determined by simply pressing the plaster. If after such a manipulation there is no trace left, then proceed to grout. To do this, use a grater or industrial grater. The tool is pressed to the surface and in a circular motion process the perimeter of the base until smooth.

Plastering hard-to-reach surface areas

In order to plaster corners qualitatively, as well as such hard-to-reach areas as communication points, the manipulation is carried out last after the mortar has solidified on the main surface. The agent is applied with a spatula. To process the corners, use an angled spatula, after which leveling out the solution and grouting the surface after setting the composition.

The video in this article shows how to properly use cement mortar for plastering a surface.

If you know how to properly plaster walls with cement mortar, you can bleach yourself without the help of professionals. This will help to save a certain amount of money and gain experience in the reconstruction of the building foundation.