Materials for facing the foundation: an overview and the right choice

Today there are modern materials for facing the foundation, which are widely used and have excellent technical properties and indicators.

The content of the article

What are the types of foundation

There are several types of foundations that are distinguished by their practicality:

- Protruding base.

- The dropping down.

Features and specifications:

- The height of the foundations of these types can be different. In some cases, it reaches 70 cm.

The main function of the foundation is to protect the house from the penetration of the cold. It should be well insulated with expanded clay and dry algae, and it will also be obligatory to make concrete pouring on the floor of the building. This applies to internal work. - The base itself, as a rule, is made of refractory red brick, which is able to retain heat and is very strong and durable.

Tip. When building a house, it is best to use a sunken socle, as it is less susceptible to weather conditions due to the fact that it is reliably protected by a protruding wall of the structure.

Materials that are used for facing the foundation of the house (basement)

At the moment there are such materials for facing the foundations:

- Decorative plaster.

- Decking.

- Porcelain tile.

- Siding.

- Natural and fake diamond.

- Clinker tiles and so on.

- See a photo from an example of such a basement design.

Tip. Most importantly, the foundation lining materials were practical and moisture resistant.

Plaster decorative plaster

This decorative product is used to outdoor decoration already for a long time. There are several types that have excellent characteristics and a wide range of surface finishes.

So:

- Decorative plaster is moisture resistant and is not affected by weather and climatic conditions.

It is relatively durable and does not burn. It also withstands temperature extremes and is frost-resistant. - The agent is applied quite simply. All actions are similar to applying a leveling layer of plaster to the surface.

Tip. When decorating the base with decorative plaster, it is worth considering that the surface of the brick must also be previously prepared and for better work, a special building grid is mounted on the brick.

- For leveling, as a rule, concrete mortar is used, which is prepared with your own hands from sand, cement and water. It is superimposed using spatulas of different sizes and before lining it with decorative plaster, it will be obligatory to impose several layers of starting plaster on it, each layer of which, after complete drying, is treated with sandpaper.

- Layers of decorative plaster are applied with similar tools: trowels and with the help of a building level, so that the finish is smooth.

Tip. To ensure that the tool is firmly fixed, the surface is pre-primed.

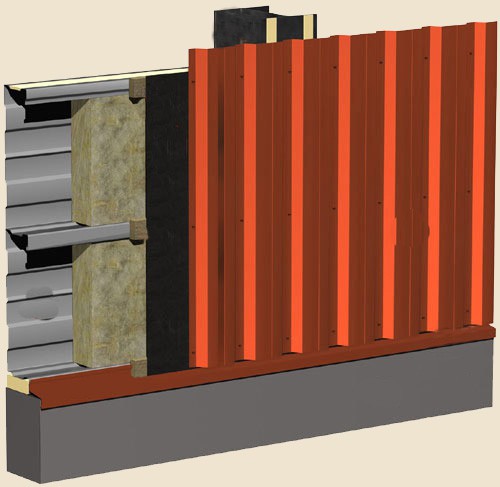

Decking in plinth facing

Such a facing material for the foundation, as corrugated board, began to be used quite often. It is moisture resistant and does not burn.Also does not respond to changes in temperature and climatic conditions.

Material Feature:

- This is due to the fact that the corrugated board is made of stainless steel, which is not subject to corrosion, and it can be used for a rather long period of time.

- On its surface has a large amount of design. There are imitations of various kinds of brickwork or brick masonry and more.

The surface itself may be:

- Smooth or embossed.

- Matte or glossy.

- All this makes it possible to create a unique decor of the base of the building.

Installation Features:

- It is mounted quite simply, and for this it will not be necessary to level the surface first.

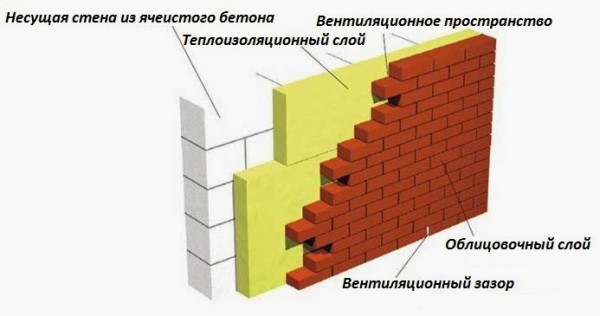

- Corrugated board itself is a cold material and it will be imperative to insulate the base with thin hard sheets of polystyrene foam or polystyrene foam, which are mounted on the surface using special plastic fasteners.

Tip. You need to fix corrugated board on the crate and it is desirable that it be made of metal profiles.

- Heavy profile pipes are not used for such work, since corrugated board does not have a large mass. The insulation is inserted into the cells of such a lathing and only after that a sheet of material is attached to it.

It is used for this:

- Screwdriver and screws.

- Building level, tape measure and pencil.

- Hacksaw for metal or grinder for cutting corrugated board.

You need to overlap the sheets of material so that moisture does not provide an opportunity to get under the finish. This can adversely affect the thermal properties of the base.

Porcelain tile for facing the foundation

Porcelain stoneware facing materials are very popular. They can be in the form of tiles or panels.

Porcelain stoneware itself is a type of ceramic tiles, only with increased strength indicators. Its composition includes several grades of clay and feldspar, which is the main component of natural granite.

Hence the name went - granite.

Material Specifications:

- Porcelain tile is moisture resistant and frost-resistant. It is not affected by weather and climate conditions, and it is not exposed to fire.

He is able to retain heat well and additionally insulate the base is not required. - The thickness of the material may be different, as well as its size. The most optimal parameters for porcelain tiles are 30x30 cm or 30x60 cm.

It is very convenient to work with them and in almost every case their size corresponds to the height of the base, which will make it possible to have not too much construction waste after facing the structure. Thus, much less money is spent on the material itself. - Porcelain tiles are mounted on the principle of ceramic tiles. To do this, you need a solution of concrete or a special glue, which is intended for exterior finishing work.

Also need:

- Spatula.

- Building level.

- Tile cutter.

- Decorative putty.

- Cruciform lighthouses.

Tip. If concrete mortar is used for the installation of porcelain stoneware, then its strength can be increased with the help of special additives that are used in the manufacture of the mortar itself.

The video shows an example of the installation of porcelain on the basement of the building.

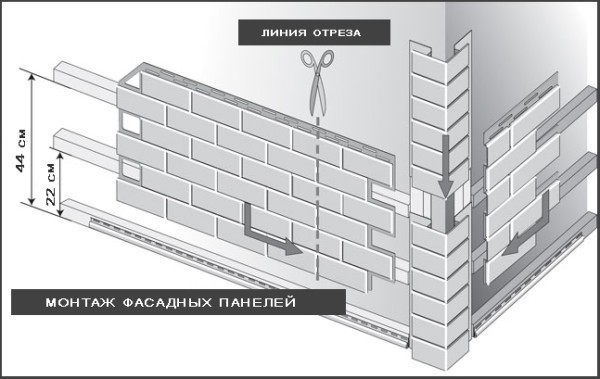

Finishing the base with siding

The options for facing the foundation with siding are quite diverse. This is due to the fact that the material has a wide variety of design on its surface and size.

There are siding panels or just stripes. Everyone will be able to choose the best option for finishing the structure.

Material Feature:

- The popularity of a siding is ensured by its price and excellent technical indicators. It is relatively durable, as it will not deform under the influence of physical or mechanical forces.

- It does not perceive the effects of moisture and various weather and climatic conditions. Also, the siding does not burn, but can only melt and at the same time it will not emit harmful substances into the atmosphere.

- He is not afraid of frost, which makes it possible to use it in decoration even in those regions where there are very low temperature conditions in the winter.

- It is mounted quite simply and previously on the surface for this a wooden crate is mounted.

Tip.

Since wood has the ability to absorb moisture well and at the same time deform its structure, after installing this type of lathing it is coated with paint or varnish. The layers of such products are able to protect the surface of the tree from the harmful effects of climatic and weather conditions.

- Also in this process, insulation and insulation of the basement of the building are carried out and sheet materials such as polystyrene, extruded polystyrene foam and so on are used for this.

Siding is mounted using self-tapping screws and a screwdriver. Initially, a starting strip is attached to the crate, which will ensure smooth installation of the material.

All work of this type is quite light and do it yourself will not be difficult.

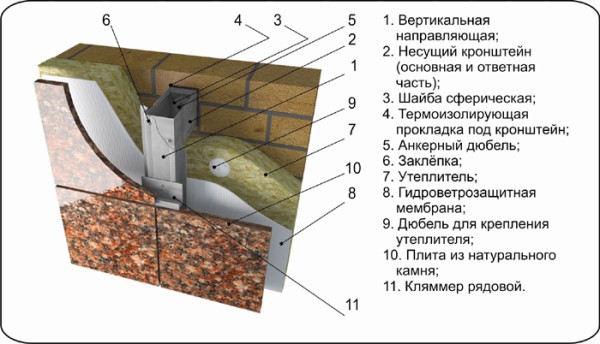

Natural and decorative stone for basement

These foundation lining materials have similar properties and characteristics. They are very durable and can be used in decoration for a long period of time (natural agglomerate has no life at all).

So:

- The stones are moisture resistant and do not burn. They are not affected by weather and climate conditions. They are easy to install and for such work there is no specific instruction.

The principle of work is a trip to the installation of simple ceramic tiles. You will also need to level the surface using concrete mortar or plaster.

Tip. If the decorative stone does not have a large mass, then the natural stone is quite heavy and in order to perform its high-quality installation it is necessary to first strengthen the surface by using a reinforcing wire mesh.

- It is attached to the surface of the base and only after that layers of plaster or concrete mortar are applied to it. For the installation of the material, a concrete solution is also used, which is resistant to weather conditions and temperature extremes.

After solidification, it will also have greater strength than glue and thereby securely fix the stone finish. - If it is necessary to make insulation and insulation on the base from the outside, then insulation or insulation material is initially applied, which is covered with sheets of OSB or moisture-resistant drywall and natural or artificial stone is already attached to such surfaces.

When using drywall, the preparation of the surface for the installation of materials will consist in its priming.