Facing a concrete base: options and technologies

The plastic cladding of the base is a rectangular panel, with imitation of brick or stone on the front side. The main criteria for choosing such a finish for foundation walls is its low price and ease of installation, allowing you to sheathe the base yourself.

And yet, no matter how skillful the imitation, with the beauty and strength of natural, and even artificial stone, it can not be compared. For example, sandstone lining of the basement is done once, and it serves as much as the building itself will stand.

It is about such a facing that will be discussed in our article.

The content of the article

Base stone

Of course, everyone knows about the beauty and durability of marble and granite, but in the decoration private houses these types of stone are practically not used. The blame for the high cost of the stone, as well as its monumentality. It is more common to see it on the facades of administrative buildings.

But there are many other breeds that can be used to finish the foundation. You can get brief information about them by reading the table below.

| Stone category | Its varieties | Characteristics and Application |

| Wild stone | Facing the plinth with a plinth is one of the most popular types of finishes. Its reason is not only the affordable price of the stone, but also its original shape.

In appearance, the stone is diverse, it can vary not only in thickness and configuration, but also in color. In nature, there are options from a gray-yellow hue to terracotta.

| |

| Wild stone | Rubble stones are called fragments of various rocks formed during their extraction. Therefore, it is also called career. It can be rubble waste, and can be manually selected.

There is a bedy boot, which resembles a small brick in shape, and is ideal for erecting the foundations themselves, the walls of buildings and wells, fences. This type of boot is selected in the process of careful sorting.

The installation process of a rounded buta is quite complicated, since it is impossible to automate it, and each element for laying has to be selected manually. | |

| Sandstone | For exterior cladding, various types of sandstone are also used. This is an inexpensive natural, and almost eternal stone with a layered structure.

Mergel has a mixed, clay-calcium composition with various impurities, on which the density of the stone depends.There is a chalk marl, which crumbles under your hands, and there is, for example, dolomite - a very durable and beautiful stone.

| |

| Sandstone | Tuf is a volcanic rock formed by sedimentation of ash. Accordingly, this stone is mined in regions adjacent to volcanoes, and is widely used in construction and architecture.

Sandstone-tuff is used both for exterior and interior decoration, and as an additive to decorative plaster. Stone crumb is added to the cap lining solution, and a beautiful relief is obtained on the surface. | |

| Sandstone |

|

Travertine shades vary between yellow-gray, cream, pinkish-white. Thanks to the delicate pastel palette, the facades are not only faced with a socle of travertine sandstone, but also have a solid finish on the exterior walls. There is decorative plaster imitating the texture of travertine.

|

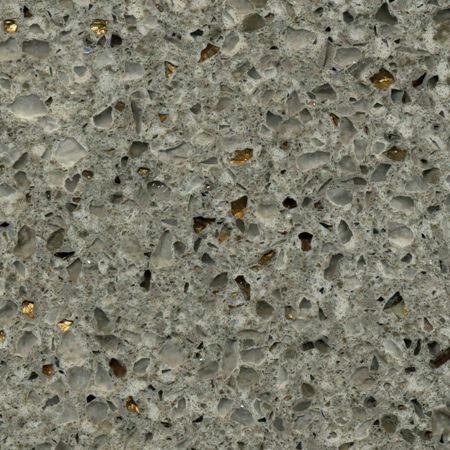

By their properties, and aesthetic qualities, many types are not inferior to natural stone artificial stone. Take at least an agglomerate.

As a raw material for its production, crumb of granite, quartzite, or marble is used. The binder is cement or polymer resin.

So:

- To give the stone a rare shade and mosaic texture, various minerals, colored glass, and metal shavings are added to its composition. Agglomerate is produced: both in the form of blocks, and in the form of large plates, and tiles.

Here it is, along with well-known porcelain stoneware, used for facing various surfaces, including the basement.

- Facing agglomerate can have several options for the front surface: rough, polished, polished, and bouchard. This artificial stone has even wider application than many types of natural stone.

And it is not only wall coveringbut also flooring, countertops, bar counters. High technologies used in the production of agglomerate make it completely immune to humidity and, consequently, to low temperatures. - The content of quartz sand and granite chips in the composition gives it not only increased strength, but also resistance to aggressive influences, including acid. Depending on the thickness and configuration of the tile, it can be mounted both on glue for facing the base and on the crate.

- There are other types of artificial stone, which are made of gypsum, concrete, acrylic resins that can simulate almost all existing types natural stone. In addition, they also surpass analogues in many qualities.

Having samples and a compound (silicone molds for casting), many types of stone can be made at home.Fortunately, in construction stores you can buy dry balanced mixes, and the manufacturer's instructions will explain how to make the composition, and how much time it will take for it to harden. - The lining of the base with the Besser has become extremely popular today. This is a decorative stone used for landscaping local areas, the construction of fences, interior and facade cladding.

At its core, this stone is a type of facing brick with a chipped surface. Namely, hyper-pressed brick, which is made from a cement-sand mixture, by the method of semi-dry vibropressing.

Besser for facing the base fits perfectly, only, due to its solid weight, the technology of laying the stone is different from other methods of decoration. We will tell about some of them in the next chapter.

Cladding process

Any work in construction, and even more so, finishing, begins with preparation. And facing the base with stone, tile or brick is no exception.

The list of these works depends on the design features of the foundation walls, their height, quality, presence or absence of the blind area.

So:

- Under the stone cladding, performed by the adhesive method, the surface of the foundation walls must be leveled. If the work is carried out on the plastered foundation of the old house, it must be completely cleaned without relying on the apparent strength of adhesion of the screed to concrete.

After cleaning and removing dust from the surface, waterproofing should be done using a penetrating primer or liquid glass. - If you are not going to insulate the base, you can proceed with the installation of the plaster grid. You can do without it only if you use stone, porcelain stoneware or agglomerate tiles of a small format.

All other types of stone, especially such heavy ones as booth, paving stones, or the same besser, require a reinforcing mesh, and not only. As preparatory work, a concrete blind area should also be equipped, on which the cladding will rest.

- In a house under construction, it is more convenient to use a ledge of the foundation of the strip foundation as a support. If it has a columnar or pile structure, a shallow strip foundation is made between its supports, especially for facing. We will not describe the technological process of pouring it now, to familiarize yourself with it, you can watch the video.

- Finishing the base with heavy material, usually done in parallel with the erection of walls. Ordinary stone: plastushka, tufa, or marl, are lightweight, and do not require additional such cardinal preparation. A regular metal corner can serve as a support for the first row of such cladding, it will also ensure horizontal laying.

- If it is necessary to insulate the basement, before tensioning the grid, a heat-insulating material is mounted. Mineral wool is not suitable for this purpose: it is attractive to rodents and absorbs moisture perfectly, which greatly reduces its service life, and it will not withstand the load from the weight of the stone.

For the base, which will be faced with stone, it is better to take either polystyrene foam or foam glass.

- If you prefer the first option, take plates with the marking PSB-S35. The density of the PPP of this brand (25.1-25 kg / m3), can withstand significant loads, even the weight of hyper-pressed brick or rubble stone. For plaster, composite panels, tiles mounted in a frame way, you can take less dense (16-20 kg / m3) polystyrene foam, grade PSB-S25F.

It is better not to use a material with a low density, which everyone knows as foam, for this purpose, if you do not want to ruin everything. - Foam glass is also available in plates with a size of 600 * 300 mm, but with different thicknesses 50; 100; and 150 mm.They can be mounted both on special mastic and on the frame, as there are options with groove-ridge joints.

Moreover, they produce varieties of plates with front finishes of stone chips, which simultaneously serve as heat-insulating and decorative material.

- After the insulation is finished, the finish remains. The stone is mounted on an adhesive specifically designed for this purpose.

Heavy types of stone can also be laid on a normal solution, only you need to add either PVA glue or a liquid plasticizer, which is sold in plastic canisters, and is usually dosed at the rate of 1 liter per 100 kg of solution. In any case, this information will be indicated on the package.

If we turn to the services of specialists, the prices for facing the basement will depend on the type and size of the stone, the installation method - well, and on the region, of course. Facing with stone tiles of a small format, without insulation, will cost at least 1200 rubles / m2.

If the stone has to be sorted, selected according to the configuration, cut, anchored, such work will cost from 3000 rubles / m2. And if you need to clad not only the base, but also the walls, the cost of decoration will increase exponentially.

So, learn to do everything yourself, take work very seriously - and you will succeed!

The lining of the rubble stone base is suitable for any decoration of the facades. If the decoration of the external walls is made of facing brick, then the base is also better to be faced with facing brick, with a surface under a torn stone.