Brick cladding: process technology

The brick lining of the basement gives the whole building solidity, emphasizes its geometric shapes. Moreover, the foundation for brick facing can be not only strip, but also pile, or columnar.

Naturally, the finish technology will depend on its design. We will tell you about this process, plus a small instruction on which brick for facing the foundation is better to choose.

The content of the article

How to tile a pile foundation

Due to its design features, pile foundations under facing brick do not have a basis to which the lining should be tied. And since the brick can be used to erect this very foundation, it is easiest to do this so that it does not need subsequent finishing.

So:

- The construction of the pile foundation is such that its aboveground part can protrude both over a short distance (20 cm) and quite high. Crowns the structure with either reinforced concrete grillage or wooden foundation beams, if the house, for example, is log.

- Most often, the basement walls erected on a pile foundation with a small ledge are only decorative in nature, since such a small space under the house is practically impossible to use practically.

In this case, the foundation is fulfilled with brick facing, the role of which, for example, siding panels can play. This is a snag, or as it is called: a false base. - If the aerial part of the foundation is more than one meter high, the construction of basement walls makes sense. And brick is the most convenient material that can be used both constructively and decoratively.

In fact: why build walls from building bricks, and then think about how to finish them, when you can masonry from facing bricks. - The wall, which will have purely decorative functions, can be laid out in a half brick. And if at the same time you take a hollow brick and lay it on an edge, you get a beautiful perforated wall with good ventilation.

The use of clinker or hyper-pressed colored brick will give a wonderful decorative effect.

To equip a full-fledged ground floor, wall thickness should be at least one and a half bricks. This work is not easy to do, and the price will be considerable, but in this case you get not only a decorative effect, but also practical benefits.

Indeed, in the basement you can equip a subfloor for storing supplies, a technical floor for communications, and even a garage.

Arrangement of the base under the walls of the basement

In any case, in order to build a brick plinth, you must first make a shallow-deep strip foundation of monolithic concrete, on which its walls will have to rest.

So:

- The base can be located, depending on the construction of the foundation, between the piles. In this case, the surface of the base will be flush with the surface of the walls of the house.

The second option is a basement device along the outer perimeter of the pile field. In this case, the basement walls will protrude outward. - When starting to do the construction of the basement with your own hands, you need to keep in mind that the foundation for the facing brick must withstand the weight of the masonry, and does not carry other loads. The main thing is that its width should correspond, or rather, slightly exceed the wall thickness.

If the masonry is carried out in one and a half bricks, the wall thickness will turn out 380 mm. - A foundation with a width of 40 cm is needed for such a wall. It is advisable to calculate its height, depending on the height of the masonry.

For a base with a height of 50-60 cm, a base height of 20-30 cm is sufficient. - So, along the perimeter of the pile field, a trench of 20 cm deep is dug. A compacted sand cushion 5-6 cm thick is arranged in it. Then, formwork with a wall height of 25-30 cm is constructed from the unedged board.

Its bottom must be covered with roofing material, with a good overlap on the walls. This is done so that moisture from the concrete does not go into the sand. - Concrete for pouring can be bought ready-made, but can be made on site. Concrete grade should not be lower than M200.

If you mix the solution yourself, you will have 2 parts of sand and 3 parts of crushed stone with a fraction of not more than 8 mm for 1 part of cement. Both sand and gravel should not contain impurities of lime and clay.

Cement is taken M400. The water in the solution should be no more than 30%. - If full basement walls will be erected, it would be nice to add a composition like Penecrit or Penetron to concrete. This additive will protect concrete from moisture and destruction from repeated cycles of freezing and thawing.

Ready concrete is poured into the formwork to half its height, and is carefully rammed. Then, a reinforcing mesh is laid on its surface, which is welded or knitted with steel wire from reinforcing rods with a diameter of 8 mm.

After that, the rest of the concrete is added.

Brick basement masonry

And now, the foundation is ready, the concrete has gained strength within 28 days, and you can proceed to further work. The masonry is carried out in dry weather, and if it rains, it is covered with cellophane, so that the solution that has not yet set is not washed out of the seams.

So:

- Before laying the first row, the concrete base is covered with roofing material. In order to properly set the corners, the brick is first laid out without mortar over the entire width of the basement.

To achieve perfect evenness of the masonry, measurements are taken from all sides using the building level. - When the measurements are finished, you can start mixing the solution. Its composition should be as follows: for one part of cement M400 - three parts of sand. Water is added to form a plastic mass.

- For air circulation, vents are arranged in the lower rows of the masonry. Each master has his own method.

It can be a replacement of a whole brick with a half, or some vertical joints that are not filled with mortar. If this is your first time doing this, watch the video first. - A master class from professionals will teach you how to correctly tie corners, as well as perform reinforcement of masonry using a steel strip, which should be made in every fourth row.

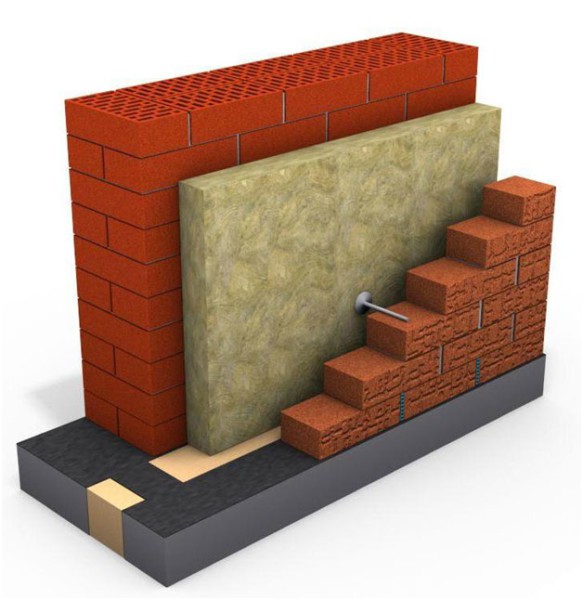

- When the basement is planned to be used as a technical or residential premises, it is possible to perform well masonry with insulation, as in the photo above. In fact, this is one of the options ventilated facades, with the help of which it can be performed not only facing the foundation for a brick house, but also decorating the walls with bricks of any building.

Only in the case of masonry, the width of the foundation for brick facing should take into account not only the size of the ventilation gap, but also the thickness of the insulation. By erecting such a base, for the main wall, you can take an inexpensive building brick, and for decorative - choose a beautiful option with a relief on a spoon.

House on a strip foundation: facing the basement

If the house is on a strip foundation, brickwork can rest directly on it. To do this, you need to dig the foundation and, measuring its free ledge, assess the situation.

So that it could be done brick cladding, the width of the foundation should be at least 12 cm.

This is if the insulation will not be made:

- You ask, why so many? We answer: the width of the brick is 12 cm.

Building norms and rules allow the masonry protrusion from the foundation surface to a third, that is, 3 cm. So, at twelve centimeters of the protrusion, it is possible to place the brickwork so that a ventilation gap is formed. - If the protrusion is smaller, then in order to clad the base with brick, the foundation will have to be added. In fact, you will perform the same concrete base that we talked about in the previous chapter, only at a different depth. The pouring technology, in this case, is no different.

- Given that there is already a basement wall in such a house, you only have to lay out the decorative wall, linking it together with the supporting wall using flexible connections. Their rigid end is clogged into the existing wall, and the flexible end is monolithic in the solution between the bricks.

At the end of the masonry, its surface is treated with hydrophobic impregnation, which will prevent the brick from absorbing moisture, and, accordingly, will extend its service life.