Decorative brick cladding inside and out

Decorative cladding brick is an artificial stone designed to decorate any surfaces that are competently prepared for installation. It is recommended to prepare the foundation for laying with stone at a temperature of + 5 ° C to + 25 ° C, that is, in the warm season, and lay the facing and decorative brick on walls that have stood for at least six months in the construction so that the shrinkage of the walls manifests itself in the form of shrinkage and temperature cracks .

The content of the article

Integration and Transformation Processes

Ancient brick can only be wood and stone. Brick is the common name for any piece building material that has a parallelepiped shape and weight, which allows you to manually erect structures from it, perform masonry for repairs.

A distinctive feature of bricks is their bright pronounced product elongation, which allows laying in various ways. Continuous horizontal rows with mutual overlapping of individual bricks in vertical layers, this dressing allows you to get a geometric figure of a brick.

Brick Distribution History

For centuries, brick manufacturing technology has changed slightly. Do-it-yourself brick-making was reminiscent of the bread making process.

So:

- Each individual brick was obtained from its portion of clay “dough”, which was shaped like a parallelepiped.

- Billets were stored and dried under the sun during the summer period.

- For firing, temporary makeshift stoves made of dried-out raw brick were used.

- The industrial revolution in the 19th century changed the whole technology of brick production.

- Special machines appeared (clay balers, runners, rollers), invented ring kilns, molding presses, which made it possible to increase brick production hundreds of times with an increase in the quality of finished products.

- Machines made it possible to mix the raw materials more thoroughly and evenly, molding devices provided high geometric accuracy, and new drying plants and furnaces completed the process of maintaining optimal temperature and time parameters at each stage of technological production.

- Around the first half of the same century, Dutch masters received a clinker brick recipe - the highest achievement of brick art relevant to this day.

Note: Brick and ceramic building material are produced using technology that is not much different from the technology of their ancestors, but some manufacturers are looking for old masonry and produce small batches to order.

Separation of brick assortment

The assortment of manufactured bricks began to be divided by signs and areas of its application. If you look at the photo and video materials, you can visually trace the process of integration and turning brick into decorative rock and facing bricks in modern finishes.

- Building bricks are used in the construction of foundations, walls, partitions, it is easier to say the box of the building. The material is required to withstand static loads and serious, atmospheric "shocks".

In the normative documents of GOST there is one for this material, and the names are different: masonry brick, rough, ordinary, second-hand, the name most likely reveals the scope of materials and expresses their difference. Brick buildings are characterized by high strength, excellent frost resistance, sound insulation.

Often there is a brick with a corrugated surface, which contributes to strong adhesion to the mortar. - Front, ceramic, decorative facing stone and brick, front, smooth many names, but one essence - facing of surfaces and obtaining a beautiful internal and external appearance of buildings. The brick is subject to the requirements of resistance to external influences, strength, frost resistance and at the same time have a uniform color.

It has two smooth, front, adjacent sides, and two are rough for strong fixation in masonry. - A separate group is highlighted in textured and profile material. The front surface of the textured brick is embossed, imitating various unusual surfaces, right up to the shell of the turtle.

Profile brick is used for decorative elements of columns and arches of buildings. - The poverty of brick painting was caused by the red or white clay used, which was painted red, white, and their combination was yellow when fired. Modern technologies use dyes, so an unlimited variety of colors is selected for any complex, decorative finishes.

- However, these are not all the tricks to get marvelous colors. The application of glaze makes the surfaces shiny, additionally protects and increases the decorative capabilities of the material and allows you to obtain the desired colors.

- Kiln brick is intended for operation at temperatures above 1000ᵒС, is prepared from special, fireclay, refractory clay. Fireclay brick got its name from raw materials.

It is distinguished by a slightly yellow color and granular structure, which distinguishes it externally and does not allow it to be confused with other material. It is used strictly for its intended purpose in stoves and fireplaces. - The shapes of building and finishing bricks are optimized for hand grip. The multiplicity of the dimensions of the products allows to obtain and preserve the beauty of the longitudinal and transverse joints, and non-standard sizes significantly save the binder solution.

- Unary and one-and-a-half bricks are divided into solid and hollow, withstand heavy loads, and voids give additional heat capacity.

- The entire double brick is prepared lightweight, voids have rounded holes or through slots. Advantages are to reduce the weight of the masonry, retain heat, good sound insulation, therefore, ceramic bricks are hollow.

- Brick is labeled according to the specific load M-100, which means that the material can withstand a load of 100 kg per cm², then M-125, M-150 and further.

- Country and cottage construction use the M-100, 125, M-150 is already used in high-rise construction.

Attention: The coefficient for the middle band in frost resistance should not be lower than f -35, which serves as a guarantee of longevity of the structure.

Criteria for choosing artificial material

The history of modern construction, decoration, ceramic and brick products is still ongoing and not completed. In the external and internal decoration of houses, offices (seeModern design and office decoration), summer residences, cottages and apartments used popular, decorative facing stone and brick.

According to the designers, this environmentally friendly, safe and natural material helps to realize the most daring, intricate and extraordinary ideas.

Material properties for interior work

Decorative cladding brick is a product in shape resembling tiles, and physical characteristics are close in properties to natural stone. The material is prepared from high-quality natural components, and then subjected to refinement processes, which allows you to give the product an original shade, appearance and pattern.

So:

- Due to the applied modern technologies in production, decorative facing bricks, the price of which depends on manufacturers and quality, have a number of important characteristics and properties.

- Decorative masonry made of facing bricks is durable and its service life is estimated for decades, and the attractive appearance from year to year remains unchanged.

- High durability of products and the ability to hide their young age, disguising themselves as antique.

- Not combustible, but decorative facing bricks and its full-bodied varieties are used in the interior for facing fireplaces and stoves.

- Products are resistant to aggressive environments, do not work with adverse conditions and chemicals. Brick tile does not fade and does not lend itself to temperature changes.

- Decorative facing brick has good heat-insulating qualities. The walls lined with it will always be warm and allow you to keep the optimal microclimate in the room.

- They have low moisture absorption.

- High abrasion resistance.

- Decorative brick cladding is characterized by high aesthetic data. An important distinguishing feature in various geometric patterns, shades.

- Universal product when used. The various, non-standard geometry of the brick tile (rounded and beveled corners, curly edges) allows you to use door and window openings without creating cuts and create architectural inserts in the interior.

- Good soundproofing.

- It repels water. With a hydrophobizing solution that protects the brick from moisture, the products are covered and allow them to serve longer and in more difficult conditions.

- The main criteria for products are still aesthetic data - texture, pattern, color and its shades. Creating an original atmosphere can be those materials that fit perfectly and meets the overall design.

Attention: You can decorate complex elements with mosaic or figured products, using non-standard forms to get ornaments.

Surface preparation

Instructions for working with internal surfaces that have various old coatings, which it is time to get rid of:

- Decorative brick cladding on a painted surface is made only after its complete cleaning. The paint is removed with a grinder, iron brushes.

Plaster is examined for strength and reliability, blisters are removed and these areas are plastered again. Cement-based plaster is preferable, but gypsum can also be used.

Prior to laying products, the surface must be treated with a primer or concrete contact agent. - The spaces covered with wallpaper are freed and cleaned of them, glue is removed. The surface is dried, checked for bearing capacity, restored if necessary, and the surface is treated with a primer.

- Decorative cladding with a brick on a drywall sheet is carried out on a processed concrete contact means and a dried surface.

- Metal surfaces are cleaned of rust and other contaminants, a metal mesh is attached by welding or by cutting itself, plastering and priming of the resulting structure are performed.

- Decorative masonry with brick facing wooden surfaces indoors is carried out in several stages. A frame is created, a crate with standard sections 60x60 cm in size, gypsum board is attached on top, primed and only after that the lining begins.

Attention: Concrete-contacting agent is used for bonding materials with opposite properties (gypsum, concrete).The tool is selected depending on the material from which the tile is made.

Artificial brick exterior

Decorative facing brick and the execution of work from it are simply in great demand. Immediately after its appearance on the construction market, consumers appreciated its wide selection, the characteristics are no different from natural counterparts, but in many ways superior to them.

So:

- Indeed, even the most dilapidated house will look beautiful, rich and respectable with brickwork.

- What problems may lie ahead for uninformed customers? Masons are hired who have no idea about the thermophysics of the walls, and offer them to take up the design of this house.

- The work is being carried out, the externally decorative masonry of the facing brick looks just fine, the customer is satisfied and has no complaints, and it is not visible that the “cake” on the wall was made incorrectly.

- The consequences are deplorable, especially for a tree; it simply rots.

- Warming is carried out carelessly, which can lead to the accumulation of moisture, the thermal efficiency of the insulation decreases, white efflorescences appear on the brick.

- A beautiful, brick facade hides all the mistakes and miscalculations in the work, but only the first time, they will appear, better sooner rather than later.

How to avoid trouble

So:

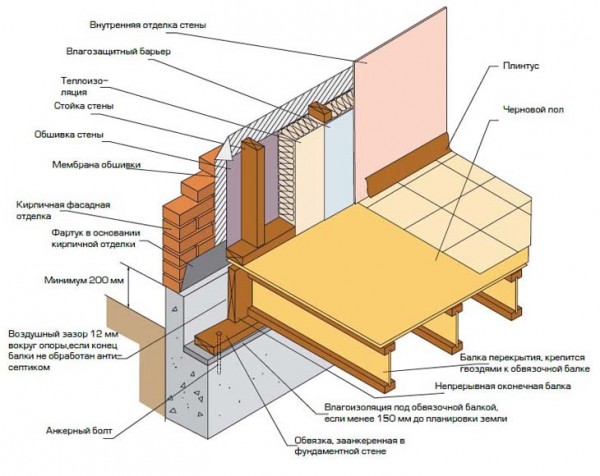

- It all starts with the foundation and it’s good if it is timely filled with such a width that will allow facing masonry. However, often facing the old building requires topping up the foundation.

- The width of the part that will support the brick should not be less than its width and should be 12 cm plus 3-4 cm for air gap, if without insulation. The need for thermal insulation adds thickness to the insulation.

According to SNiP, the extension of the brick cladding beyond the foundation is allowed no more than 4 cm, corresponding to a third of the width of the brick. - Wall insulation is carried out with mineral wool material with a sufficiently high vapor permeability index. This indicator must be taken into account when warming and lining walls with bricks.

- All unnecessary elements of platbands and facings are removed from the walls.

- Of the boards 100x25 mm exposed frame. Between the slats there is a distance of 55-58 cm, under mineral wool insulation, which are produced of such sizes.

- The frame is more conveniently attached to the cuts itself, but metal corners can be used.

- Insulation is laid 10 cm thick.

- On top of the insulation, with a construction stapler, a waterproofing, windproof, vapor permeable membrane is attached.

- Why a membrane? It turns out that such a film works like a "nipple" system, removes water vapor from the insulation to the outside and prevents their penetration back.

Attention: It is important not to confuse the side on which the protective film is attached to the insulation, the rough side is facing the insulation.

- Membrane fastening is carried out in horizontal stripes from bottom to top, joints are overlapped with an overlap of 10 cm.

- Decorative cladding is carried out with bricks and without insulation, everything determines the structural material of the walls of the building.

The best aesthetic effect is achieved with a brick of not only different colors, but also of different reliefs. To do this, pigments are added to the solution that contrastly highlight the jointing.