Ceramic facing brick: GOST 530 * 2012

Clay brick has always been and remains today, one of the most popular, constructive and finishing materials. This material is truly universal: with its help you can build walls of any shape, including round.

Thanks to the existing masonry technologies, they can be made insulated, monolithic, to make the exterior of the facade, or interior decor. What are the requirements of GOST for facing ceramic bricks? And what types of clay bricks do exist?

The instructions and video in this article will tell you about this.

The content of the article

What you need to know about brick

All types of ceramic bricks, both building and facing, are made according to one standard - its name is indicated in the header. It extends to clinker bricks, despite the fact that its manufacturing technology has significant differences.

- The unsurpassed strength characteristics of this material allow its use where heavy loads are expected. Naturally, these are foundations and bearing walls, as well as arched vaults, and outer lining of furnaces and chimneys: both domestic and industrial. So, it is not surprising that its price is much higher.

- It should be noted right away that this standard does not apply to special types of bricks, which include acid-resistant and fireclay (refractory) bricks, as well as ceramic stones for paving roads.

Terms and Definitions

Brick, as such, is a piece of ceramics used for masonry on mortar. If we talk about a single brick of a normal format, then it can be described as follows: this product is in the form of a parallelepiped with right angles, and the following dimensions: length 250 mm; width 120 mm; height 65 mm.

To familiarize the reader with the appearance of the products, as well as with the terms used in construction, when it comes to brick and masonry, we offer a small overview in the form of a table:

| The appearance and name of the brick | Definition of the term |

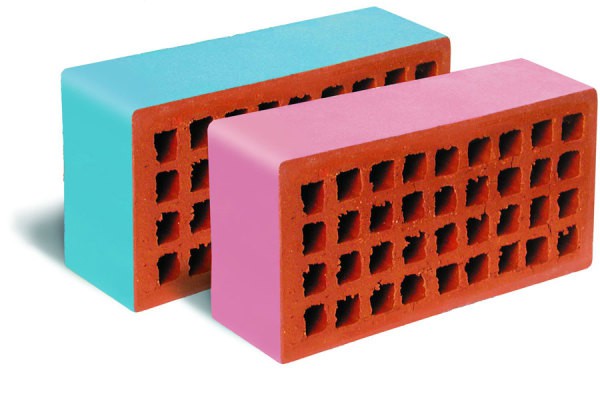

| Normal building brick with normal dimensions and no voids. The cost of this material is the most affordable, since it is not decorated in any way. For the construction of walls with your own hands - this is the most often bought type of brick. | |

| In it, voids are either absent completely, or their number does not exceed 13%. This is exactly the option you see in the presented photo. | |

| This type of brick has voids of various sizes and configurations in its body. Moreover, the voids can be through and through. | |

| This product may have any shape other than a box. | |

| As already mentioned, this product has a higher strength and low water absorption. Beautiful appearance allows you to use it as a decorative material, including in landscape design. Its dimensions correspond to the normal format of building bricks. Clinker bricks can have any form and decorative surface treatment inherent in ordinary bricks. | |

| Despite the fact that this product is a decorative material, according to its characteristics, it should correspond to ordinary brick. That is, the front brick provides the masonry with the required strength, and at the same time decorates it. | |

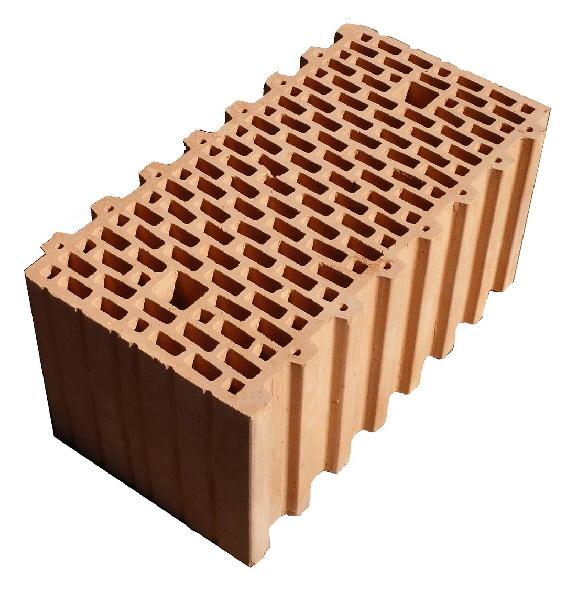

| A hollow ceramic product, different from a large format brick, designed for masonry walls. The nominal thickness of the ceramic stone must be at least 140 mm. | |

| This type of product has protrusions and grooves on its vertical faces that allow them to be joined. This connection allows you to not use masonry mortar in vertical joints. By the way, stones with grooved, and tongue-and-groove joints, facial are not. |

As can be seen from the table, the brick can be ordinary and front, as well as solid and hollow. Voids can be located in the brick body not only vertically, but also longitudinally.

As for ceramic stone: in order to reduce weight, it is made only in a hollow version. The desire to avoid additional loads on the foundation is understandable.

Marking and basic requirements

Brick is marked according to strength characteristics: from M100 to M300, only 7 types.

The strength of clinker brick from M300 is just beginning - products with maximum strength are marked M1000. Stones are marked similarly, but their strength level is lower than even ordinary brick: from M25 to M300.

- In addition to the normal format, the brick may have other sizes, which are regulated by the standard 530.2012. There are only two length options: 250 mm and 288 mm. The width may differ from the nominal size of 120 mm, both smaller and larger: 60 mm; 85 mm vs 138 mm. There are only three options for thickness: 55 mm; 65 mm vs 88 mm.

For ceramic blocks, the size range is much more diverse. The most common stone size: 380 * 250 * 188 mm.

To complete the laying of ceramic stone, additional elements are also provided. Moreover, by agreement of the customer with the manufacturer, their sizes may differ from those prescribed in this standard.

Appearance of products

Naturally, the highest demands are placed on the front brick. Firstly, it should have no less than two face faces: one longitudinal, and one end face.

And the way to finish them is left to the manufacturer. This can be two-layer molding, glazing, textured shotcrete, engobing, relief. In general, there are a lot of options.

- Ordinary bricks come in only two versions: with a smooth surface, or a relief applied to it. All products can have both a natural color and be dyed in their mass. As for the requirements for the appearance of ordinary and front bricks, they also differ.

- For example, if for ordinary products a small percentage of defects in the form of cracks, broken edges, edges and corners is allowed, then this is completely unacceptable for front brick. The reasons for such strict requirements are understandable, because the surface cladding masonry not plastered.

- It remains to add that when designing objects where brickwork of walls is supposed either decorative cladding of facades, the brand of products, as well as their density and frost resistance, should be prescribed in the working documentation.

- GOST for ceramic tiles, which often imitate brick, even more strictly regulates the requirements for appearance, especially when it comes to products of the first grade. The use of such tiles gives undeniable advantages.

- Firstly, it costs a lot less.

- Secondly, due to the low weight of the cladding, the load on the foundation is reduced. And if you need to brick the old house, it is, of course, better to use tiles. At the same time, the facade does not at all lose the individuality of the relief that the brick provides. This is easy to see by looking at the photo above.

Conclusion

The brickwork is heavy and needs to be supported on the foundation.It is necessary to dig it up and, if the width of the tape is not enough, add it. All this is an additional cost and labor - something that every customer seeks to avoid.