Brick home decoration: inside and out

Facing brick, as a material for the decoration of facades, has long been known. Recently, interest in him has grown tremendously.

And this happens, thanks to the proposals of brick manufacturers, constantly expanding its range. That is why the brickwork of the house, outbuildings and fences, can represent a single ensemble, individual, and very organic.

The content of the article

Types of facing bricks

Brick used for facade decoration, differs from building bricks: both in appearance and in technical characteristics. Most often, in any case, in external finishing works, hollow bricks are used.

So:

- Four surfaces can have a decorative look in a brick: two spoons and two pokes. But there are also such options when only a smooth surface has one smooth surface and one spoon.

Naturally, the price of such a brick will be slightly lower. - According to the manufacturing method, facing brick is also different. The most popular type is glazed brick.

It has good strength and resistance to low temperatures, has a shaped, embossed, chipped or curly surface.

- The relief on the decorative surface of the brick can be very different: imitation of the bark beetle pattern, the surface of the skin, the effect of cracked plaster, or geometric patterns. Such a variety helps to execute an original drawing or a panel on the wall, to beautifully design the gables, window sills and corner zones.

- Another type of decorative brick, clinker, has a higher strength and color scheme. It is excellent for both exterior decorating and for interior cladding, for example: stoves, fireplaces, chimneys (seeFinishing the chimney outside and inside the house), working walls in the kitchen.

- From this material, you can lay out the internal partition, and decorate it in the loft style. The color gamut of products in this category is the widest, which allows for various types of brick home decoration.

Sometimes, the surface of the wall, faced in this way, may look like a stone finish.

- The most durable, used where special operating conditions of the building are required, is hyper-pressed brick. Its production uses high-quality Portland cement and ground shell, and not clay, lime, and sand, as in other types of bricks.

- It is molded in molds under very high pressure. In general, a completely different technology - no firing, and evaporation in an autoclave.

The structure of this brick is dense, without pores, it has clear dimensions, an incredibly smooth surface and the highest strength. - Masonry of such a brick is performed without jointing, after which it forms a monolithic surface. This type of masonry is the most economical in terms of mortar consumption, even compared to clinker brick.

- As you know, a hyper-pressed brick having such valuable qualities is used not only to achieve a decorative effect, but also to strengthen the load-bearing walls of a building. With the same success, it can be used as a structural material for the construction of walls.

The dimensions of the facing brick can vary, but the main demand falls on the standard size 250x120x65 mm, called a single. The thickness of one and a half bricks is 88 mm, and double - 138 mm.

In this case, the remaining parameters remain unchanged.

We carry out facing

Such type of facade decoration, like brick cladding, is used only in low-rise construction.

The load on the foundation is too great, even when hollow bricks are used. This is the first.

And secondly, the production technology of this work is quite laborious. Therefore, when a multi-storey building is being erected, the house is finished under a brick using facade panels.

Our site has a lot of articles on this topic. Read them, watch the video, and we'll talk about natural brickwork.

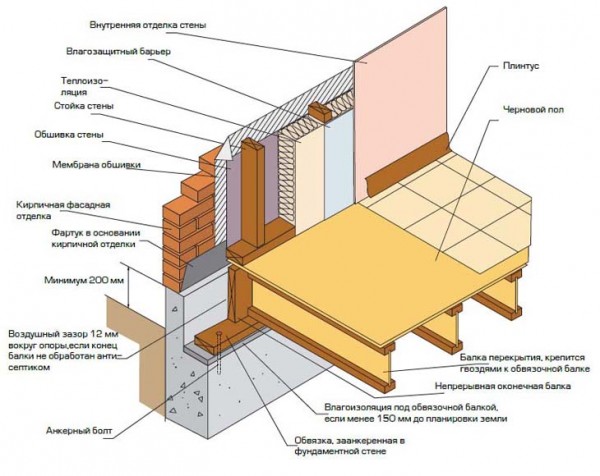

Since it should be based on the foundation of the house, it is necessary to start with it. Usually, the type of facade exterior design is designed in advance, especially if it is a facing brick.

In this case, the width of the foundation in the house under construction will be calculated not only on the load-bearing wall, but also on the decorative one. When planning to revetment a building that is already in operation, it is necessary to dig the foundation, examine it and calculate: is its free width enough for brickwork.

But most likely, the foundation will have to be added. This process will depend on the construction of the foundation.

It can be a pile or column design with a monolithic grillage. But more often all the same, the foundation in private houses is tape, and it is most convenient for supporting brick cladding.

So:

- We will not go into details of the foundation device, this is a separate topic. We will only say that the width of the part on which the brick will rest must be no less than its width, and this is 12 cm, plus 3-4 cm for the air gap. This is if without insulation.

- If necessary, insulation, here should be added the thickness of the insulation. According to SNiP, brick cladding can protrude beyond the foundation by no more than four centimeters, which corresponds to a third of the width of the brick.

The main thing is that the bundle of the decorative surface with the supporting wall is correctly performed. - Our instruction will offer you a brick cladding option without insulation, since the arrangement of the thermal insulation layer may be different, depending on the structural material of the building walls. Anyway, after reading the article, you will get only a general idea of this work, and you won’t be able to do it yourself at once.

- You can connect decorative masonry with the wall of the house in several ways. One of them looks like this: a galvanized steel anchor is driven into the wall, placing it so that the opposite end passes between the facing bricks.

Cured masonry mortar will hold the anchor firmly.

- There is another way. In this case, not anchors are used, but dowels and steel wire fixed on them.

The second end of the wire will be sandwiched in rows of bricks, but should not go outside. Such fastenings should be made every four to five rows, placing them, sixty centimeters from each other.

Door and window sills are tied even more tightly.

Solution work

The masonry mortar can be purchased ready-made dry, or you can make it yourself using M500 cement and fine, sifted sand. The ratio of the components should be as follows: for 1 part of cement, 4 parts of sand, and so much water is added to obtain the consistency of a dough.

To avoid the setting of the solution, it must be kneaded in small quantities, and quickly develop:

- When performing masonry, the closest attention is paid to the seams. They should be uniform and as neat as possible, no more than 1.5 cm wide.

These are horizontal seams. A vertical should not exceed a thickness of 1cm. - Before starting work, a batch of bricks is soaked in water. When saturated with moisture, the brick will not pull it out of the solution. Each master has his own working methods.

Many people use a square bar template. - The first row is laid in level, and start from the corner.Having laid out five or six rows, they pull the cord along which the next rows are aligned.

It is better if several lower rows are reinforced with a fine-mesh metal mesh. - When they reach a window or door, they do not interrupt the row, but cut the brick to the desired length. This is done in order to maintain the correct layout.

The exposed masonry mortar must be removed immediately, without waiting for it to set, removed from the wall and wiped with a damp sponge.

To achieve the best aesthetic effect, wall bricks can be used not only in different colors, but also with different reliefs. For the same purpose, pigments are added to the masonry mortar, which contrastly emphasize the jointing, as in the photo above.

Believe me, there are many options for designing a brick surface. And if you set out to learn how to do it yourself, we wish you success!