Facing expanded clay blocks with brick: features of the work

Building material for building a house is currently diverse, as well as finishing material for building decoration. The houses from expanded clay blocks became the most popular and the houses from expanded clay concrete blocks with brick lining are most often found.

The content of the article

What is expanded clay concrete and its properties

Expanded clay was invented in the Soviet Union. He replaced the construction of familiar cinder blocks.

This material consists of:

- Cement.

- Water.

- Clay that pre-foams and then burns.

Features:

- Due to its production technology, expanded clay concrete has excellent thermal insulation properties and, as a rule, does not need additional insulation.

- Finishing work of such building material should be carried out without fail, since it does not have an attractive appearance.

For such purposes, various finishing methods are used:

- Siding (seeDIY siding decoration: how to do it right).

- Plastic.

- Decking.

- Natural and artificial stone.

So:

- Despite this, the most popular is the facing of brick houses from expanded clay blocks. This facing material has a large selection of types and shades, which have significant differences in their properties and methods of use.

- Expanded clay house with brick cladding is very durable and reliable.

It has excellent sound and heat insulation properties. The service life of such a building is at least 60-80 years.

Tip. Despite the fact that claydite concrete itself is a warm material, all the same in those regions that have a very cold climate in winter, claydite-concrete walls with brick lining must be subjected to additional insulation.

- To do this, foam, polyurethane foam or extruded polystyrene foam is used. Do not forget also that expanded clay concrete has the ability to pass air and steam.

Because of this, it is necessary to make a ventilation gap, especially if the wall of expanded clay blocks is faced with brick made of expanded clay concrete, and not a simple ceramic or other type. - The main advantage of expanded clay blocks is that they are large in size, which makes it possible to save on the purchase of building material and not very large weight, which allows you to build a foundation not too deep.

- The masonry of this material can be performed similarly to brick, but here it is worth considering that in two planes of the material there are small holes that increase the vapor permeability of expanded clay concrete and they must be adequately protected - plastered or simply coated with various finishing materials. The construction of houses from expanded clay blocks themselves are characterized by the use of concrete mortar, which contains a small amount of purified sand.

Expanded clay blocks:

- Very strong and reliable, as they can withstand significant mechanical and physical stress.

- Frost-resistant - withstand very low temperature extremes.

- Fire-resistant - for a long time they can resist a direct source of fire.

- Practical and economical - due to its size, building a house does not cost too much money, and the process itself is very fast.

- Environmentally friendly - this indicator in the characteristics of the material is the most important. Expanded clay is safe for human health and does not harm the environment.

Note.

It is also worth considering that the total price for building a house from expanded clay concrete will be several times lower than when using brick or other stone. The size of the expanded clay concrete block affects everything.

Brick for facing a house from expanded clay blocks

There are several types of such material that are very widely used for finishing expanded clay concrete:

- Expanded clay brick.

- Facing brick.

The last type of brick is also called front or front.

Expanded clay brick and its properties, characteristics

Facing expanded clay concrete brick has become popular relatively recently. All this is due to the fact that a lot of its color schemes have appeared.

What is this type of brick? Everything is pretty simple.

It is very similar in production technology to expanded clay block. Only its composition includes expanded clay in granules.

Is he:

- Durable - not able to deform under the influence of physical and mechanical strength and under its own weight.

- Frost-resistant, as it freely tolerates the effects of very low temperatures and various weather events.

- It is not exposed to the process of decay and a variety of fungal diseases.

- It is an excellent heat and sound insulating material.

- Practical, as the surface is moisture resistant and does not absorb dirt, dust (it does not need to be cleaned).

- Long-lasting, since its service life is at least 10-15 years.

Features:

- In addition to all this, the facing of walls from expanded clay blocks with bricks from similar raw materials is environmentally friendly.

- A brick of this type itself also has large dimensions of 60x30x40 cm. Its weight is very small, which will not make it possible to exert additional load on the base of the structure.

- The surface of expanded clay concrete bricks is embossed, from the back sides it is even. With its help, even laying of the material is ensured. It is possible to use it in the decoration of a fragmentary stone.

- Expanded clay brick breathes and its installation requires an air cushion between the wall and the back of the material. Thanks to it, moisture will not accumulate on the inner surface of expanded clay concrete, which in most cases is a source of mold formation.

Facing brick, its types and properties

Brick lining of expanded clay block can be performed:

- Front (ceramic).

- Silicate.

- Clinker.

- Facing over-pressed.

Facing brick for finishing expanded clay blocks has its own advantages, it:

- Brick finish It has an attractive appearance that does not require additional design.

- The standard size, only there are solid or hollow bricks. The latter type is most often used in decoration.

- Moisture-resistant, as it is not able to perceive by exposure to a humid environment.

- Practical - its surface is not contaminated and does not require frequent cleaning.

- Long-life - the term of its operation is at least 30 years.

- Frost-resistant - able to withstand very low temperatures.

- Wear-resistant - the surface does not wear and does not deform over time.

It is characterized by a very easy installation when using a solution of cement or concrete.

Installation of facing bricks

In such works, instruction is not required. You just need to follow certain rules and recommendations.

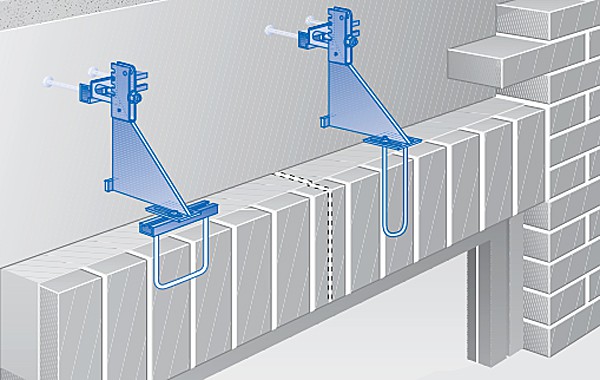

Initially, it is worth considering that the cladding should be connected to the main wall of the building and have a foundation, which for the cladding and for the house can be common.

Note. To do this, metal burdock made of thick sheet is made on the wall. Reinforcement is welded to them, which will be hidden in the concrete mortar during the laying of the facing brick.

To install the facing brick itself you will need:

- A solution of concrete, which is independently prepared from sand, water and cement in certain proportions. They depend on the size of the container and the quality of the material itself.

- Spatula for applying mortar to the surface of a brick.

- The construction level for smooth and high-quality masonry cladding.

- Coloring pigment, which in some cases is added during the manufacturing process of concrete mortar in order to give a decorative and original masonry seam.

Even if in this area there is no specific work experience, then you can complete the whole process with your own hands and without much effort. As a rule, certain questions may arise during the work and to quickly find answers to them, you can watch a video that shows the process of laying brick facing.

Ceramic facing brick and its properties

Brick lining of ceramic expanded clay blocks has become popular for a very long time. All this is due to the high quality indicators of this type of material.

It has several advantages and is able to decorate any building with its appearance.

It has standard sizes and design shades: red and white. In some cases, other colors are found.

Silicate brick:

- This type of material is a bit outdated at the moment and is not used as often as before.

- It also has excellent quality indicators, only in most cases, under the influence of moisture, silicate brick can release salt, which protrudes on the surface and spoils the appearance of the whole facade decoration.

Clinker brick:

- The cladding of a house from expanded clay blocks with brick clinker is distinguished by its durability and wear resistance.

- This type of material is a modern analogue of ordinary facade bricks, only with improved characteristics and properties.

- It retains heat even more and does not allow cold air to pass through.

- It has standard sizes and shades.

Hyperpressed facing brick

This brick has excellent properties, as it is made by pressing clay dough under the influence of high temperatures and only then undergoes firing. It is characterized by high strength and reliability.

Brick lining of expanded clay concrete walls of this type can have a variety of imitations, since on the front side of the material the surface is torn and with different additives. It also has various shades, due to which the original design of the facade of the building is created.