Decorating the arch with mosaics: how to do it yourself

Recall the golden childhood. Multi-colored glass pieces, pieces of robbed ware with drawings, building secrets from them and showing each other their findings, exchanging identical shards for others.

Then there was no idea that all these important elements serve as mosaic components. Mosaic, as a form of art, was known several millennia ago.

Why spend time laying small pieces of the photo above when there are whole tiles and even rolls of decoration materials? Mosaic was undeservedly forgotten before the appearance of the finished material, compiled on the principle of a set of multi-colored pieces into a single whole.

The content of the article

Mosaic Use Range

Mosaic is made by small tiles, different in texture and color.It is subdivided into several types and quality indicators.

It is widely used:

- Facing the walls of the living room, kitchen, bathroom (seeMosaic decoration of the bathroom - how to do it yourself).

- Finishing stairs.

- Facing the surface of the pool bowl, arches.

- Finishing the exterior walls of buildings.

Material characteristics

It is realistic to do the laying of the material with your own hands, without resorting to the help of specialists.

It is important to determine its characteristics for a certain type of work:

- Mosaic material is water resistant.

- Lightfastness, which means it does not fade under the influence of sunlight.

- It has impact strength, but can break if the tiles are cut incorrectly.

- The mosaic is resistant to abrasion and does not respond to aggressive cleaning products.

- It has a slip coefficient and a certain temperature range.

Attention: Mosaic for floors with high humidity (pools, bathrooms) is made with a special coating that protects against slipping.

- The ability to use mesh technology and advanced paper technology when laying mosaics.

Types of mosaic tiles

Mosaic matrices with a size of 300x300 mm are produced and can consist of 225 tiles of 20x20 mm each:

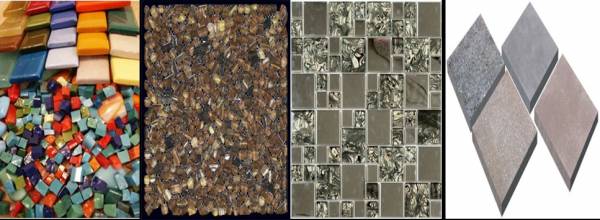

- Glass mosaic tiles (see the figure from left to right) is used in the decoration of swimming pools, bathtubs, building facades. This beautiful material harmoniously fits into your extraordinary fantasies.

- Ceramic mosaic tiles are a variation of the same tiles. It has excellent characteristics and is used to create an exclusive and attractive interior.

Affordable price and no delivery problems. - Metal mosaic appeared on the construction market relatively recently, but has already firmly consolidated its position. The material is made of thin stainless steel attached to a rubber base.

It has various shapes and colors used for wall and floor work. - Concrete mosaic tiles with high strength and frost resistance are used in the outdoor decoration of the sidewalk, building, border. Marble impregnations in the tile allow it to be used in rooms with high loads.

- Broken tiles and a little patience allow you to get your own, popular mosaic. The process of making mosaics from broken shards of tiles, utensils can be viewed on the video on the Internet, where not only drawings, but masterpieces of craftsmanship are presented from it.

Mosaic delights for finishing straight and rounded surfaces

The surfaces of various shapes and the ability to create artistic paintings from mosaics, the laying of mosaic material were divided into two types, depending on the methods for obtaining the final result.

Direct way

- It was known in the old days, it takes time and a "full hand".

- Mosaic wall decoration begins with the formation of adhesive and laying out the modules.

- Laying allows you to immediately get a picture from the mosaic, but it is quite easy to "tear" the whole picture. It is not easy to lay out modules at the same distance from each other.

- The direct way of laying is not forgotten, there are specialists with many years of experience in creating mosaics in large areas.

- A small mosaic picture in a direct way, for training, you can do it yourself to gain experience.

Reverse method or finished mosaic module

The mosaic is created on the basis of paper or tracing paper, on which the modules are stacked with the back side up (hence the name reverse method).

So:

- The acquisition of a construction, industrial empire, which allowed to combine individual modules into a matrix.

- Matrices are assembled into a single coating canvas, and it is applied to the adhesive layer.

- The modules are fixed on the surface, the upper base, which has performed its auxiliary function, is removed.

- The modules fit perfectly together at the same distance.

- Laying and decorating the walls with mosaic tiles from the finished modules is no more difficult than using ordinary tiles.

- Laying even large areas with a mosaic requires relatively little time, and the choice of various patterns, color combinations is quite wide.

The technological process of laying the mosaic matrix

Mosaic is a very versatile material in the interior, instructions for its use in any room and on any surface does not apply to complex work.

So:

- Mosaic finishing of the arch and straight walls begins with the preparation of the surface on which the mosaic matrices will be glued.

Attention: The surface is primed and leveled to marble smoothness, so that the unevenness of the base does not appear when laying the mosaic.

- The surface should be perfectly clean, and most importantly dry (less than 3% humidity).

- The glue is selected for each type of mosaic tile, and it must be white so as not to change the color of the mosaic.

- The spatula-comb for applying the adhesive composition should have teeth 2 times the size of the side of the mosaic module. For example, for a mosaic tile measuring 20x20 mm, you need a spatula with a tooth size of 40 mm.

- It is recommended to pre-mark the surface in order to avoid irreparable errors. Matrix sheets are pre-laid out according to the drawing and accurate measurements are made.

The wall is marked with control marks corresponding to measurements, which significantly reduces the time for direct laying of the mosaic. - The coating is laid on the applied adhesive. The first row of matrices is laid especially carefully, since it is the basis of the entire further process.

- The sheets should not be strongly pressed at the beginning of laying, only after fitting all the sheets, the matrices are deeply pressed and fixed in the solution.

Attention: Do not allow the adhesive to get on the front surface of the mosaic, so as not to spoil the entire canvas.

- After the final drying of the solution, grouting is performed, the protective layer is previously removed.

- The paper layer is soaked with a spray gun and then removed. The work is done neatly and starts from the top corner.

- A rubber trowel in the vertical and horizontal directions is grouted.

- Movement diagonally and with the same spatula removes excess solution. This operation is performed no earlier than 30 minutes after the initial setting of the trowel.

- Using a damp sponge, trying not to wash the grout out of the seams, the mosaic is cleaned until the solution is completely dry, otherwise it is removed much more difficult.

- The mosaic surface is finally polished with felt.

After completing work with the mosaic, it remains at rest for 30 days before use. With all the recommendations and careful care, this unspoiled beauty will delight the owners until the next desire to update the interior.

That's all, decorative arch finished.