A wooden wall, as part of green housing - we build a house of wood ourselves

Starting to build a house on their site, many are thinking that it would be nice to build a house of wood, which will be warm, cozy and comfortable. Someone just wants to save on building materials, and someone wants to be closer to nature, constantly breathing in the scents of the forest. Others, on the contrary, refuse such buildings, thinking of less reliability and the possibility of a fire.

Our today's article will be devoted to this issue, but we will not only talk about how good or bad such houses are. We will consider what types a wooden wall can be, how to properly erect it and how to finish it if necessary.

The content of the article

All you need to know before construction

As a material for walls, wood is used in the construction of one and two-story buildings. During construction, it is best to use finished factory products manufactured in forest-rich regions.

Now enterprises offer prefabricated structures, which, after delivery to the site, are assembled by a qualified team. Hiring builders and lifting equipment in this case is inevitable, as it will be impossible to hoist up massive logs with your own hands.

Although, if you are a physically strong person who is not afraid of hard work, then you can find yourself the same assistant and use the old method of lifting. On two guides installed at an acute angle, the logs are pulled upward by looped ropes.

Caution! It will be difficult for an unprepared person to withstand such a load. Be careful and careful. If you feel when lifting that you are no longer able to hold it, in no case let go of the rope, otherwise your partner will be pulled down, following the heavy log. Act like that. Tell your partner that you are tired, and begin a smooth return descent. Take a break and try to climb again.

Types of wooden buildings: pros and cons

Wood structures can be constructed in five ways.

They may be:

- Timbered - logs of a natural cylindrical shape are used for construction. Such buildings have great air tightness, high strength and will be very durable. The old log buildings, which are at least 200 years old, have been preserved in excellent condition.

Among the disadvantages it should be noted: high consumption of wood, so the price of such structures is very high; it is impossible to finish the premises immediately after the construction of the box, as the shrinkage of log cabins and shrinkage of wood lasts about 1.5 - 2 years.

- Cobblestone - are made of rectangular timber, interconnected by dowels or spikes included in the nests. They have the same properties as log buildings. In addition, it is necessary to note the figured processing of the bars, which is done at the factory of the material manufacturer.

- Shield - walls are built from large wall panels, which are a stable spatial system. They are the basis for fastening fencing elements to them.

- Wireframe - such buildings have a supporting skeleton frame, which is sheathed inside and outside with a tees. The internal space between the casing and the racks is filled with loose or tile insulation. There is also a technology for filling this space with straw soaked in a liquid clay solution. It is rammed and hardens, forming a monolithic core of the structure.

Unlike log and block buildings, such houses do not give strong shrinkage, and can be finished immediately after construction. It is very important that during the construction of the house effective heaters are used that will cope with frost in the latitude where the house stands.

- Frame-shield - combines the two previous methods. Shields made of wood or OSB panels are wound onto the installed frame, filled with insulation from the inside and sheathed again, but on the other side.

The main advantage of frame-panel construction is the saving of material, and hence the construction budget. Subject to all norms, requirements and technologies, as well as with proper care and decoration, such a structure will last for many years.

Take Europe, where such construction is very popular for more than one century. For example, German houses in the Fachwerk style. These are also frame buildings, which can be not only beautiful, but also warm.

A common drawback of wooden buildings is the fear of fire and water. These problems can be prevented by treating the material with special protective compounds.

Materials and tools for work

Which wood is better for a monumental wooden structure?

According to sanitary standards and thermal conductivity properties, conifers are best suited. In addition, they have the correct shape of the trunk, the wood is easily processed, and due to the content of resins and volatile, it tolerates moisture better, which means rotting. Moreover, the cost of such a forest is much lower than that of hardwood.

To make logs for construction, it is better to cut down the forest in winter. Such wood is drier and will be easier to process. Branches and branches are immediately cut off from the trunks, then they are sanded so that insects that can spoil the material do not accumulate under the bark.

Then the wood goes to the plants, where it is dried, they will give the desired shape and cut out the grooves.

For work you will need the following materials and tools:

We have listed only the basic materials and tools, the rest we will mention during the description of the construction process.

Work with wood

And now let's describe how these or other wooden walls are assembled, about which we wrote above. The instruction will not be very detailed, but it will be quite enough to theoretically "be savvy" in this matter.

The construction of a log house from logs

First, a little terminology so that an inexperienced reader does not get confused in the text:

- A crown is a fully stacked row of logs along the entire perimeter of the structure;

- Komel - the lower part of the log, having a larger diameter than the other;

- The croaker is the sawn side of the log on one side not the entire length.

Chopped log walls are the most time-consuming to install. They are made in the form of a loghouse, consisting of separate, connected with each other rims. Logs at intersections at the corners are joined at the notches.

For the middle strip of Russia, logs with a diameter of 22 cm are used. The first, the lowest crown, is made of logs that are 2-3 cm thicker than the main ones. This crown is called a salary.

To fold the logs into a crown, round grooves from 12 to 15 centimeters wide are cut at their edges. The blanks are sawn off or sawed up from the side of the log, which will be turned into the room. For logs laid on internal walls, the slab is sawn from two sides.

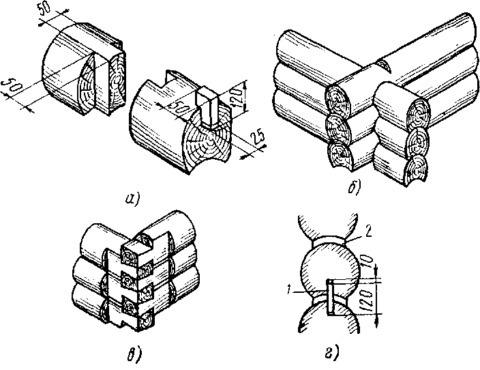

Logs are connected as follows (only the main methods of fastening are listed):

- a) Vertical ridge - used to connect the logs in length;

- b) Cutting into the bowl with the remainder - this compound is used in the corners of the building;

- c) Cutting into the paw without a trace - an alternative to the previous method. For clarity, see the diagram;

- d) Bonding logs into round grooves with the installation of additional spikes.

When assembling the crowns, the logs are stacked with knots in different directions alternately, while the joints of the crowns will be spaced apart. The crowns are laid grooves down to prevent further water from flowing. A tow or moss is laid between the logs to seal the joint.

The rows of crowns are interconnected by spikes with a cross section of 25x50x120 mm, around the entire perimeter. They are inserted into nests, which are previously cut down in logs, at a distance of 1.5 - 2 meters. At least two spikes are installed in the piers, which are no less than 15-20 centimeters from the corner.

After all the walls are folded, the seams between the crowns are caulked by tow. After 1 - 2 years, the shrinkage of the building will end - the house can settle at 5% of the original height. After shrinkage, the seams must be re-caulked.

Installation of a log from bars

This type of construction is not so time-consuming, since it eliminates the need to process parts manually. The beam is manufactured industrially with all the notches and grooves for their bundle. Builders can only assemble a house as a constructor.

It is also worth noting that the consumption of wood is significantly reduced, which cannot but affect the cost of construction.

Unlike structures made of logs, such walls are assembled immediately on ready foundations - without preliminary bedding for 9 months.

Depending on the climatic features of the region, for the construction using bars with a section of 150x150 or 180x180 mm. For internal partitions, options of 100x150 or 100x180 mm are enough.

Bars are hardly stacked on each other. A resin tow is laid between them, after which the seams are additionally caulked. So that water does not penetrate the joints, a 20x20 mm chamfer is removed from the upper edge of each beam.

They are connected in the corners of the bars in different ways, but they are all alike - grooves, ridges, cuttings and more are cut out on adjacent parts.

The rows of bars are interconnected. To do this, use wooden dowels with a thickness of 3 centimeters and a length of 6, or with stainless steel dowels, of the same diameter. The length of the nagel is 60 cm, and it passes through all rows.

Unlike a log building, although not always, a block house does not look so impressive, therefore the facade of such a house is usually faced. This should be done after shrinkage of the structure, and after repeated caulking.

The following materials are most often used for facing (cm. Decorating the house from logs):

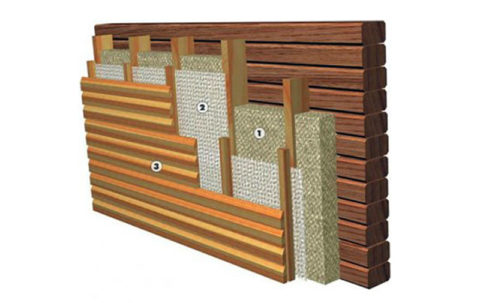

- Board or lining - will give additional protection to the walls from moisture and wind. If necessary, an additional layer of heat insulator can be laid under the casing.

- Brick - protects walls even better, and adds fire resistance to them. Masonry is carried out in half a brick, with an indentation from the wall of 5 - 7 cm, to ensure sufficient ventilation clearance. For the same purposes, from the bottom and top of the masonry leave air.

Ventilation of such a facade is extremely necessary, otherwise after a while the logs will begin to rot, as they are organic material.

Panel and frame construction

We decided to combine the remaining types of structures in one chapter, since their construction is almost identical to each other.

The frame walls of a wooden house are a supporting frame, sheathed with panel or molded materials (see Frame house decoration).

The frame of such a structure consists of:

- The upper and lower harnesses are horizontally located beams on which all racks rest.

- Racks - the main bearing element of the entire structure, located vertically. The height of the rack corresponds to the height of the floor or the entire structure.

- Braces - a supporting structural element, located at an angle, and connecting racks to each other.

- Crossbars - horizontal load-bearing structural elements, usually located above door and window openings.

All elements are fastened together by nails, anchors, screws, metal clips, and also cuttings are arranged, the same as those described above.

Racks can be located at different distances - it depends on the type of wall filler, and on the location of the floor beams. Usually it is made equal to 40, 50 or 100 centimeters. The most common cross-section for a rack is the option of 5x10 centimeters.

For braces, it’s enough to use 2.5x10 cm boards. They cut into the racks flush - one edge rests on the lower harness, and the second - on the side rack.

On top of the racks are placed the bars of the upper trim, which serve as the basis for supporting the rafters and floors of the attic. To organize door and window openings, window sill racks connected to the crossbars are installed in the walls. More details are shown in the diagram above.

Today, two types of frame are used in the construction of such houses:

- The frame with external racks on two floors - forms a solid monolithic structure due to the ligament with the lower, upper and interfloor ties. The latter serves as a support for floors between floors.

- Frame with floor racks - it is also called platform. It is inferior in strength to the first version with continuous racks, but is more convenient for mass production and installation. Therefore, it is much more common.

After installation, the hollow frame is filled with insulation, which can be of four types:

- Loose - These include expanded clay, slag, antiseptic sawdust, and thermolite (a mixture of sawdust, lime and building gypsum). Such a heater has one significant drawback - it settles over time, forming voids.

- Roll and plate - various mineral wool, as well as straw, fibrolite, hardboard and shevelin insulation.

- Sprayed - this type is the most modern, and consists of spraying liquid polyurethane foam, which, having hardened, forms a monolithic windproof layer of heat insulator. It is carried out by machine, with the involvement of specialists.

Finishing a frame house is the easiest, as the sheathing with finishing materials is carried out on an already finished frame. For these purposes, lining, boards, plaster fiber or plasterboard sheets are perfect.

Advice! Before closing the frame from the inside, take care of laying all communications.

Frequently Asked Questions and Answers

In this chapter, we will talk about questions that our readers often ask when they first encounter woodwork.

Question. How to hide an untidy external corner, after sheathing the room with a lining?

Answer. For this, special wooden corners are used to protect the corners of the walls. They are nailed in a sweat or put on glue, which is not so practical. Choose a rigid fixation with nails, as the outer corners are often subjected to mechanical stress.

Question. How is mineral wool fastened to a wooden wall?

Answer. Typically, during the construction of the frame, the width of the slab or roll of mineral wool is determined in advance. At the same distance carry vertical racks from each other. After the outer side of the frame is covered with a casing, mineral wool is inserted into the left openings. If the sheets are squeezed back, then for temporary fixation you can screw pieces of the rack onto the racks.

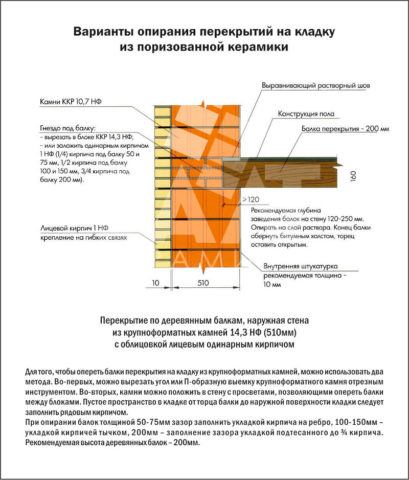

Question. How are wooden beams supported on a brick wall?

Answer. The beams are laid on top, and you can pre-lay out the recesses from the brick under the support units on the outer wall of the wooden beams. Then a bunch of anchors is performed directly, or wire to an anchor hammered into the wall. If we are talking about interfloor ceilings, then the ends of the beams are walled up in the wall. More details are in the diagram below.

Question. Do I need wooden wall cladding?

Answer. It may be required to decorate the wall or to protect it from rain. Also, sheathing is required if additional insulation is required.

Question. How to fix a flat slate to a wooden wall?

Answer. On a wooden frame, slate is attached with self-tapping screws with special layouts. Previously, in a slate, a hole is drilled at the attachment point. The work is reminiscent of drywall fastening.

Question. How to cover up a wooden wall so that it does not penetrate from the cracks?

Answer. For these purposes, special sealants in tubes are sold. This coating is done not only at the joints of the logs, but also in the cracks that occur in them over time. White sealant can additionally create a beautiful contrasting seam.

Question. How to lay a wooden wall near the stove to protect it from overheating?

Answer. The issue of fire safety is of concern to all owners of wooden buildings, especially if the house has a stove or fireplace. Adjacent walls are best insulated during the construction phase of the building, or during repairs. For these purposes, non-combustible facing materials with low thermal conductivity are used, for example, Nitikha panels, which are made of fiber cement, or GKLVO, tiled.

To learn more about the properties of such materials, see the video in this article.

What wooden houses can look like

At the end of the article we have selected for you a small gallery with wooden houses of various designs. Surely the options shown will interest many of those who are just planning to build a wooden house on the site.

- The perfect combination of natural materials in the form of wood and stone

- Light, light, energy-efficient frame house - a great solution for warm regions

- The combination of a massive log house and large windows

- Power and straight lines

- A real tower is beautiful

- Rectangular beam house

- Wooden castle in the air

- Luxury wooden house inside

- Hut at the Edge

Yes, wooden buildings are truly beautiful and attractive. If you want to have something like this near by, but there is no way to change your stone housing, then you can always finish the room with natural materials. A wooden wall in the interior will not only decorate it, but also fill the room with a pleasant woody aroma.