Plastic corners to protect wall corners: options and installation rules

Plastic corners for walls during installation are almost always used. After all, alignment of corners is one of the most difficult finishing work. Here you need to have knowledge and skills.

Usually, various corners are installed to protect the corners, it depends on the roughness and on the interior design. It is also necessary to choose the right material for making the corner, because there are several of them. It is with this finishing material that we will get acquainted today. Also on the video in this article and photo you can see the options for the practical use of this material.

The content of the article

When corner alignment is needed

Plastic corners for walls are sometimes extremely necessary, and let's figure it out right away, we need this finish option:

- In those cases when you plan to put rectangular furniture in a corner. In the aligned walls, the furniture rises perfectly.

- Also for protection against mechanical damage. If there is a large roughness, it is better not to level the surface. Because space is greatly reduced. This unevenness can be easily torn artificial stoneIt fits into any design.

- Also, if the vertical angle is not perpendicular to the axis of the earth, then not a large deviation can be completely aligned using just the corner.

Types of corners and materials for making a corner

Plastic wall corners are selected according to the type of angle.

There are two options here:

Inner corner | Internal corners generally do not fall into the risk zone, since they are difficult to access. Although it is not particularly susceptible to mechanical stress, its evenness is sometimes extremely important. |

Outside corner | But external corners are always a headache, as they are easy to damage. They do not have high strength, wallpaper can be torn off, peeling paint. For example, the transfer of large furniture or appliances, there is always a risk of damage. From this we can conclude that corners require protection. |

The corner can be made of several materials. His characteristic largely depends on this.

Let's see how much the PVC corner fits you:

| Production material | Characteristics |

| Plastic | Durable, resistant to moisture, easy to install and perfectly processed; |

| Metal | It has many positive qualities, but the cost is very high, it also has a low weight and lends itself to corrosion; |

| MDF | Durable, comparable to natural wood. Unacceptable exposure to moisture; |

| Wood | It looks beautiful, but it is highly flammable, and a moist environment is not recommended; |

| A rock | Robust, but installation time-consuming process, also has a large weight and therefore is not always acceptable. It is also quite difficult to handle; |

| Galvanized metal profile | Resistant to moisture. It doesn’t weigh much. But there are difficulties with the processing. |

Attention: The main thing is that the corners are light and durable. Then they are attached without problems and simply change during repair.

Why choose plastic

The choice will stop at the plastic decorative corners. They are the most common in use. Today, the market offers a diverse set of plastic corners. This material has a diverse color palette, and also have a good property - softness.

There are two types of plastic corners - external and internal corners. Therefore, many manufacturers paint plastic not only on the outside, but also on the inside. They have many advantages.

Let's try to summarize, this is in a small list, noting the main ones:

- They have a very low weight, which increases the level of service;

- The color scheme is diverse - from white to black;

- You can give any shape;

- Easy to cut;

- Stick well;

- Hide bumps or imperfections;

- Give straight lines completeness;

- Shelf life over 100 years;

- Pretty low price;

- The possibility of DIY installation also attracts the consumer.

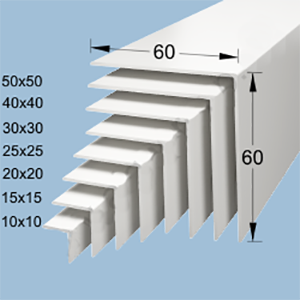

Attention: Corners come on sale all of the same length, which helps to accurately calculate the required amount and choose the right shade for you. But they have a different shelf, that’s what you need to pay attention to.

Corners are installed at the end, after all installation and repair work has been completed. Corners are glued to the wall with mounting glue for plastic. If you are doing this type of work for the first time, then you need to use corners of medium width, and the height of the plastic corners is standard 2.5 m.

Areas of application for plastic corners

Plastic corners will be real helpers in any interior. They emphasize all the lines that you want to highlight in the decor. They also help to hide all the bumps or problems in the plastered walls.

Consider situations when it is really possible to do without their help:

- When installing window slopes inside;

- When installing windows outside, to hide traces of foam, give an aesthetic appearance;

- Framing door slopes;

- For the design of arched openings (seeHow to finish an arch: forms of arches and types of decoration);

- Wall corners glued with wallpaper;

- At corners that are made of drywall, putty;

- When creating corners, when working with tiles;

- When using plastic panels indoors;

- Joint formation, when working with siding (seeAll about facing siding or sketches about the famous).

You can still list for a long time for which cases a decorative plastic corner is useful.

However, from this list the evidence of its widespread use is also visible:

- The corner is produced by heating PVC, it is given the desired shape. This corner is smooth and without cracks.

- Note that the corners are not standard. Width can be different. One side is wider than the other. Such plastic decorative corners are suitable for arched openings.

- Manufacturers produce a large number of plain plastic corners. They also depict imitation of natural material, such as stone or wood. You can find that corner that perfectly fit into the color scheme of the room.

Types of corners by type of decoration

You can determine which corner is necessary, internal or external for work, after selecting the type of finish.

- The outer corner is in the amount of 90 or 105 degrees. The plastic window is edged, with the help of plastic corners of 90 degrees, if not enough, put the second shelf.

- If two shelves are visible, then they are framed with plastic corners of 105 degrees.

- In internal works, they use a corner that can hide the joining of materials and irregularities.

- Corners put the final point in the repair - finishing work, give the finished look to the room, after repair. The main thing is to choose the right corners for your interior.

Installation of corners

Glue is the most necessary thing to install the corners. Since the reliability of fastening depends on it. On the market today, a lot of all kinds of glue are sold, each different in composition, properties.

How to choose the best glue? If you choose it incorrectly, then you can spoil the external aesthetic appearance.

Let's look at what species exist and what they are suitable for:

Fixing a plastic corner to polyurethane | It has a number of positive aspects - leaves no residue, elastic, has high strength. It is most suitable for gluing a corner with plastic panels. But there are drawbacks, it has a sharp smell and a long gluing, about two days. You need to apply such glue over the entire surface of the corner, do not glue immediately. It takes about 30 minutes to allow the glue to harden slightly. |

Fixing a plastic corner to liquid nails | The most popular glue. Gained its fame due to its high strength. It is also called mounting glue. It contains sodium carbonate, which allows you to fill the voids between the corner and the wall. It is great for gluing plastic corners with any type of wallpaper. If you use white corners during installation, it is better to buy transparent liquid nails, with other shades of wallpaper you can use any glue composition. Note that liquid nails do not spoil the plastic corners and wallpaper. Apply glue to the plastic corner with a snake. |

Fasten the PVC corner to the sealant | This is a complex glue. The choice must be approached with all responsibility. A sealant is needed to bond plastic to tile. Note that not every sealant can be used for bonding plastic. Experts say that it is better to use acrylic sealant. It is durable for bonding plastic, has no color and odor. And has increased moisture resistance. |

Attention: When deciding how to stick a plastic corner to a wall, it’s worth looking at what you will attach the corner to. Then there will not be unforeseen circumstances and the installation will be successful. Glue is applied to the corner pointwise.

Preparatory work

When we work with right angles, then we should not have any special problems. The plastic corner is easily cut using a construction knife or a hacksaw.

But with arched work, not everything is so simple. Here we need to bend a straight plastic corner. How to do it?

- From the above, we can recall that at high temperatures a plastic corner easily changes shape. To do this, we need a building hair dryer, we heat the corner, give the desired shape, fix. We continue work after the plastic cools down.

- Often corners are in the dust in the store, so before work, you need to clean them, degrease, wipe dry. Not a drop of moisture should remain on the plastic, if they do get caught, the glue will not fix well, and may fall off over time.

Note: For the arch, a corner with notches is selected. If you took a straight line, then you need to make incisions along the contour with a hacksaw.

Technology for bonding plastic corners

Each type of material has its own system for gluing plastic corners. We will analyze all cases in detail.

So that you already know exactly what you need to do:

- To glue a plastic corner to the wallpaper, you first need to pick it up. It is better to choose a corner to match the wallpaper, it looks aesthetically beautiful. Measure the height that is needed.

- After you need to cut it off. This is where the biggest problem arises for non-professionals. The plastic corner is cut at an angle of 45 degrees. Specialists do it by eye. But since you are not a professional in this matter, then you need to take a miter box and scissors for metal.

Attention: The hacksaw must be taken with metal or with a small tooth. Otherwise, the material will bite and you get an uneven cut.

- After cutting the desired length, prepare the plastic corner itself. Wipe off dust; check if there is water; if present, wipe dry.

- Now you need to prepare the wallpaper, remove the wallpaper at the junction of the corners. In this case, you need to use liquid nails.However, if you have light wallpapers, then choose a light glue, and if it is a dark shade, then any color of glue will suit you.

- Apply glue to the plastic and to the wallpaper evenly, but do not overdo it, since removing this glue from the wallpaper is unrealistic.

Glue the plastic corner to the walls in the same way as in the previous case:

- Clean the wall, prepare a corner, wipe off dirt, check for moisture. We use another glue, required for painted walls, acrylic sealant. Apply gently to the inside of the corner and attach to the wall. Exactly the same process is performed when gluing a plastic corner to the slopes.

- The most difficult type of work is attaching a plastic corner to an arched opening. Choose the type of glue based on what type of material is laid on the wall. Next, bend the plastic corner, as we described above.

- Now we turn to the hardest - cutting plastic. On the side that goes to the inner opening, we cut butt. And from the outside we leave a reserve. Then there will be an opportunity to trim. The method of gluing itself depends on the materials.

Now you have the initial knowledge of installing plastic corners. You can safely proceed to practice. As you can see, the installation process is not so complicated, but it is invaluable. And note that their cost is not high. I can even buy them with a limited budget for repairs.

Corners perfectly preserve the primacy of the room. Since they will protect the most vulnerable places in the interior. And the room will please you more than one year.

Plastic corners to protect the corners of the walls will help you maintain the geometry of the angle even under mechanical stress. And the instruction will help to do the job quickly and efficiently.