All about facing siding or sketches about the famous

Facing with external siding arises in a conversation when it comes to simple, relatively inexpensive methods for decorating house facades, as in the photo and in albums. This finishing material is like a magician, eliminating and hiding all the external defects of buildings and giving a decent appearance even to the old ragged facade.

The exterior cladding of siding is beautiful and pleasing to the eye, it is distinguished by the sharpness of the lines, and it easily fits into any landscape.

The content of the article

High quality components

Only three components make it possible to obtain siding for the outer cladding with the required quality:

- Polymer raw materials that meet the most demanding manufacturers. Special additives for obtaining color stability, resistance to atmospheric changes and temperatures.

The calculations of the compound are based on computer indicators, the mixing processes are carried out under careful control, so the output is a mass that is uniform in composition. - Quality raw materials can be "screwed up" on outdated equipment. Production and cladding technology The siding provides advanced extrusion equipment using tools from leading manufacturers.

- Before being sent to the finished goods warehouse, it is carefully monitored for a number of parameters.

- Surface quality and uniformity.

- The elongation is checked.

- Frost resistance.

- Heat resistance.

- Resistance to mechanical influences and shock resistance.

- Domestic manufacturers are striving to present their equally high-quality developments on the construction market.

- SNIP cladding siding sets stringent requirements for the material.

- It should be adapted to Russian conditions that cannot be called comfortable.

- It should not fade, burn, be frost-resistant and shockproof.

- Be on par with technical specifications or surpass import similarities produced in the USA and Canada.

- The price should reflect the quality of the material, not the cost of the aircraft.

- A wide range and many decors.

- It must be certified according to international standards and meet the requirements of GOST.

- Packaging should be comfortable and shockproof.

Attention: The instruction for facing siding allows you to identify the main characteristics of the properties. It performs a protective and decorative function.

The benefits of siding and its types for facing

Technology by cladding siding allows you to insulate the facade of the house and improve the thermal insulation of the walls. In addition to the panels, you can additionally install a vapor barrier material, a layer with thermal insulation and waterproofing.

All this is located in a small space between the wall and the siding and allows you to save useful space of interior spaces.

Cladding with siding do-it-yourself video can be mounted on any surface and type of wall. Be it brick, concrete, wood or plaster.

Siding and traditional material

| Name | Thickness mm | Planned Material Life | Expected Life | Color range | Care |

| Vinyl | 0,9 – 1,5 | 50 | 50 | 20 | Does not require |

| Aluminum | 0,7 – 1,0 | 50 | 25 | 30 | Does not require |

| Steel | 0,8 – 2,0 | 50 | 10 | Any | Does not require |

| Wood | 10 | 25 | 15 | 8 | Does not require |

| Cement | 8 | 50 | 15 | Any | Does not require |

| Plaster | – | 2-5 | 2-5 | Any | Requires |

| Lining | – | 40 | 2-4 | Any | Requires |

Which siding is better

Definitely answer this question is a very difficult task.Each species has its advantages, but there are also weaknesses.

Examples of plastic siding cladding contain information that the high elasticity index can withstand point mechanical contacts, but for a metal product they can cause irreparable harm.

So:

- The proposed collections of siding allow you to choose different materials for private construction and make their successful combination even on the same facade of the building.

- Vinyl siding under a facing brick, often found material. It is distinguished by ease of installation and ease of operation. It is affordable for a wide range of consumers.

- The plastic facing siding under a brick is prepared according to special technologies. The molds were copied from real brickwork, which allows even roughness and cracks inherent in the brick to be conveyed.

- Since the lower part of the building is subject to large deforming loads, the facing material should have an impressive thickness exceeding 2 mm, which is more than the facade analogues.

- Stone facing siding is used for basement finishing of multi-storey buildings and decoration of low buildings.

- It represents a panel, in the upper part of which there is a fastening and, although the facing options for siding for exterior decoration have the same name, vinyl and base siding, they differ in characteristics and price.

- Stone siding is 3 times thicker than vinyl.

- However, it is difficult to consider from a distance which stone siding cladding was used in basement trim, natural, natural or imitating stone.

- A compromise between the vinyl panel and the heavy material is lightweight metal, which is gaining popularity in construction.

- Facing with aluminum siding proved to be easy to install and good performance. Such a panel has absolute resistance to corrosion and does not burst during mechanical shock, like a ball or vinyl product.

Caution: Dents can appear on the surface if you try very hard, but they do not require immediate repair or replacement and are well repaired.

- The polyvinyl chloride type of finish is adapted to outdoor conditions and to operation at temperature extremes.

- PVC panels are resistant to direct sunlight, its color remains unchanged, and hail, rain and frost do not affect the finish.

- The color is chosen either monophonic or wood, tile, brickwork.

- Cladding with PVC siding makes it easy to flush dirt from the facade with water.

- Aerated concrete houses should be protected by exterior decoration from weather events that adversely affect the masonry material.

- Facing aerated concrete with siding or lining, ceramic or metal sheets, allows not only to protect the building, but also to additionally insulate it.

- The cladding sheet is attached to the crate. The fixing of the crate is one of the most important moments of this method.

- Facing with aerated concrete siding provides a hinged facade and ventilation system, because it is the most optimal method of protecting buildings of varying complexity.

- The group of materials that are afraid of atmospheric moisture can include foam concrete, which quickly darkens without finishing and takes on the form of “abandonment”.

- One insignificant nuance can negate all the efforts to arrange a home. The structure of the stone is very specific and porous, it is able to absorb steam and moisture indoors and bring them out. The lining of the foam blocks with siding should be insulated with the right material and finished with the material just for such a house.

- Simple sheathing solution foam block houses - siding aluminum, composite, fiber cement, porcelain, vinyl.

- An example of facing with vinyl plastic siding contains a lot of cases of its destruction from strong shocks, so it is better to sheathe foam block with other siding.

How to make a facing

Facing buildings with siding is carried out vertically or horizontally. Horizontal sheathing is performed by panels "herringbone", "ship board", vertical is done by panels simulating a log.

So:

- When sheathing an old house, protruding elements in the form of platbands, various decorative strips are removed from it.

- Foams are used to seal the detected cracks, cracks and holes in the walls.

- Facing the building with siding continues with the manufacture of the frame.

- For it, you can use bars of wood 50 x 50 mm, they are more often found on sale.

- It is preferable to use a galvanized profile, although its cost is 40-50% more expensive than wooden materials.

Attention: Wooden bars have a significant drawback, when using them in the installation it is necessary to take a tree with a moisture content of not more than 15-20% or in another way, air-dried wood, aged outdoors.

- The outer cladding of siding with galvanized profiles is based on the principles of work with drywall.

- The galvanized profile for siding is fixed with direct suspensions. Often there are cases when the suspension is pressed against the wall not very close due to uneven surfaces, then you need to cut the bar yourself so that the suspensions do not bend when you press the crate.

- Installation of the crate is carried out vertically 30-40 cm apart.

- The lath is installed in the corners of the house and around the openings, covering the borders of the siding fasteners.

How to set start and other elements:

- Facing of surfaces with siding begins with the installation of a starting strip along the contour of the building.

- The top edge of the starting strip should be strictly on the bottom.

- Facing the siding of buildings at the corners is done with vinyl corners to create beautiful joints of mutually perpendicular elements.

- When mounting the corner, the rule is observed, it should not reach 6 mm to the eaves overhang, and at the bottom it should be 8 mm longer than the starting profile.

- The corner is fastened with nails after 20-40 cm to provide opportunities for thermal deformation of the material.

- The lining of the eaves by siding replaced the planed board and the lining, on which the eaves were hemmed. Their disadvantage was that they quickly lost their appearance and required frequent painting, which did not decorate the eaves overhangs at all, because the layers of paint increased and began to crack and snap off.

- The cost of wood is now much higher than plastic siding.

- Lining the cornice with vinyl siding will look unsuccessful on the eaves overhangs. He also has no ventilation gaps or openings, which can lead to the collection of condensate under it and rotting of the wooden roof elements.

- Correct siding facing distinguishes two types of installation on the siding wall.

- In one case, N-rails are used; in others, they do without it.

- In the first installation method, the edges of the panels are connected by their institution into the grooves of the H-rail on both sides. These slats will form part of the facade and, when properly selected in color, they are not noticeable.

- In the second method, materials for facing siding are mounted with an overlap, for which the joints are placed “apart”. The idea is that the joint of the panels does not fall on one line located vertically, then the seams will be completely invisible.

- External cladding siding in these two ways is necessary for large surfaces on homes where the length of the element is insufficient to cover the area of the facade.

- Panels are mounted from the bottom start profile.

- Gaps between the wall and the panel of 2-3 mm are provided to smooth the deformation process when temperatures change.

- Between the panels, the gaps are provided in 6–9 mm; when fastening panels with negative temperatures, the gaps increase to 12 mm.

- Cutting of siding on the street can be done at a maximum of -10ᵒС, while the work does not endure in a hurry.

- How to facing siding in order to avoid unnecessary costs and losses? Here it is not recommended to cut all the panels at once, the elements must be cut off and shortened as necessary.

Attention: The installation of panels in the openings will be more convenient if you do not fix the J-profile at the top, then when you insert the panel, it easily bends, and after installation the profile strip is fixed.

- The panels are connected by the comb-groove method, after the locking part is triggered, even if the work is done by oneself, the last panel is attached to the crate itself with cuts or nails through special holes for fastening.

What are cladding units

The indisputable advantages of the material remove the question of how to make cladding siding at a time convenient for owners, without the use of special equipment and in a short time. All these qualities are inherent in siding.

Before installation work it is necessary to refresh the main rules and moments in your memory and then facing yourself with siding will not be difficult.

So:

- Siding changes its size to 9 mm with temperature differences.

- It cannot be stored under the scorching sun.

- They must be moved in different directions without the efforts of the workers.

- Cladding with siding itself must carry out pressure on the panel from the bottom up.

- Nails are driven into the center of the holes provided specifically for them and always straight. Nails clogged directly in the panel can cause them to crack during sudden changes in temperature.

- A gap of 1-1.5 mm is provided between the panel and the head.

- How to make siding facing so that during operation it does not flake, swell, peel and crack? Naturally, to obtain the desired result will help only very high quality material containing special additives and additives that can be used in all regions of the country with different climatic conditions.

- Here it is worth remembering the nodes that make up the cladding elements.

- Siding cladding nodes the concept is capacious, consisting of many elements. Knots are used in many areas of industry and consist of parts, elements.

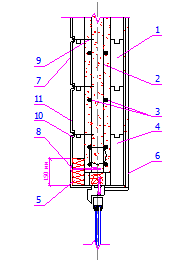

The diagram shows the cladding unit siding the outer wall:

- Reflects a building collapsible element;

- Reinforcing rod vertical arrangement;

- Reinforcing rods of horizontal arrangement;

- Jumper element;

- Mineral wool plate;

- GKLO in two layers;

- The panel itself;

- Fixing element (dowel made of plastic with a core made of metal);

- Metal anchor;

- Mortgage Profile;

- Adhesive with fire resistant characteristics.

The instructions attached to each package of panels give an idea of the monolithicity of siding sheets, which are given a certain shape and their standard sizes. Of course, now choosing the right material for the cladding assembly is not a problem.

Each material has its drawbacks, but also advantages, and they should be composed from the best options. Turning to professionals will help you make the right choice.