Facing with vinyl siding: we do it right

Facing a house with vinyl siding is quite common. After all, it will not only decorate the surface, but also protect it from external influences.

Facing the facade with vinyl siding and will be described today. It has many of its advantages, which distinguish it in a positive direction from other materials.

The content of the article

Material advantages

Before making a purchase, you should fully study the merits of this material. Maybe it will not suit you and you will give preference to another.

So:

- Facing houses vinyl siding allows you to make quality protection to the frame. Moreover, it will be possible to immediately carry out insulation, which will help reduce energy consumption and heating;

Attention: Immediately it is worth saying that there is a drawback. The panels are fastened to the frame, which can be five cm high. Therefore, this should be taken into account.

- Facing facades with vinyl siding is done on the frame, and this can be a plus. Here you can choose the thickness of the insulation yourself. This determines the mounting height of the frame. Only this should be done at the initial stage of construction;

- The whole structure will not have a lot of weight and therefore it will not be necessary to make an additional foundation;

- Wall cladding with vinyl siding is done completely with your own hands and without resorting to outside help. Therefore, the design price will be much lower;

- This is an environmentally friendly material that does not harm human health. And perfectly tolerates temperature extremes and high humidity. It has a fairly long service life.

Completing of the work

Facade cladding At home, vinyl siding is done in several stages. And this will be discussed below. An instruction will also be given that will talk about the correctness of the work.

Surface preparation and frame installation

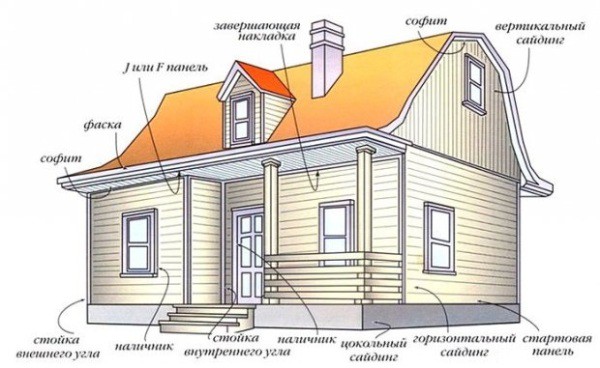

What sidingeveryone knows. Facing the facades of houses with vinyl siding begins with the proper preparation of the surface and the manufacture of the frame. After all, the correct configuration of the entire structure will completely depend on this.

If you can independently make a metal crate for siding panels, then consider that the work is 90% done. However, this is not easy to implement, since the siding frame must be strong enough to withstand extremes of ambient temperature. We will tell successively the process of all work.

The frame can be made of two types of materials:

- The metal profile that is the most durable. True, if you want to put a thick layer of insulation, then it will not work for you;

- Wooden beam. This is not such an expensive material and can be installed at almost any height.

Attention: If you have chosen the second option, then before starting work, you should treat it with antiseptics. They are in free sale. Do this in advance and this treatment will significantly extend the life of all structures.

First, markup should be made in order to install on the panel the zones where the frame will be fastened.

This is done in this way:

- From all corners of the house, lines are vertically marked at a distance of 20 cm, bearing profiles will be equal along them.

- For the bottom line, you need to make the correct markup. We put the risk at what height the frame will be attached. After that, it must be transferred to other walls. To do this, use the hydraulic level.With its help, this work can be done most accurately. Transferable;

- Now we connect the risks. To do this, we use kapron thread and simply upholstery the desired line;

- When attaching a vertical profile, starting from the corner. Using a level, ensure a clear vertical position and fasten to the brackets. It’s better to eat a plumb line for their marking. This pair of profiles on both sides of the house should be given particular attention, since they affect the integrity of the structure and the future uniformity of the wall plane.

- Now we cut the profile to the desired size and fix it. For this, a hammer drill is used. First we make a hole and after that we fasten with dowels;

- Other profiles located between them are also marked with horizontal lines at a distance of 600 mm. Draw verticals on the entire surface of the walls from top to bottom so that they are visible over the entire surface area of the walls.

Attention: When attaching the profile, please note that the panels cannot be connected on weight. Therefore, consider this when calculating.

- If you are making a frame from a metal profile, subsequently you will need to install brackets that serve to hold the profiles. They are installed on all vertical lines at a distance of 80 cm, you need to start from the bottom of the wall. Brackets in the form of "P", based on the material of the wall of the house, should be fixed to the wall using self-tapping screws or dowels.

- We establish the transverse profile with the help of a thread, which will need to be pulled along the diagonals of the frame. This will make the plane of the frame even. The height of the mount is adjustable with gaskets.

But the work is not over yet. We proceed to the most complex process, which, by the way, you will not find information in the installation instructions for siding.

It is necessary to correctly make the angle, which is set from a pair of profiles ud, twisted together.

So:

- For them, spacers are made between the corner profiles cd from horizontal jumpers, and then they are securely fixed using self-tapping screws for metal. The distance between the jumpers should be at least 60 cm. Having mounted, thus, all the outer corners of the building, a stable base is obtained where you can independently install vinyl siding.

- But it’s too early to rest, because we still need to mount the door frame and window slopes. The installation principle is the same as with corners, but the role of one of the corner profiles is played by the ud profile, which is fixed around the perimeter of the door or window openings. The upper part of the slopes must be done at the end, it should be tied with its sides to the side slopes.

I’ll tell you a little about the internal corners, which sometimes happen on the facades of modern buildings.

In such places, it is necessary to assemble the frame in the following way:

- First, we fix the ud-profile to one wall, connecting to the vertical profile using horizontal jumpers.

- Then on these horizontal jumpers it is necessary to install another profile ud in a vertical position and in the same way connect horizontally directed jumpers to the next vertical profile in another plane.

Attention: When installing the frame, one detail should be taken into account, the insulation should not be pressed. When deformed, it loses its properties. Therefore, when choosing the height of the frame, it is better to provide a gap of one cm.

So, the frame for installing vinyl siding panels is finished, now you can begin to sheathe it.

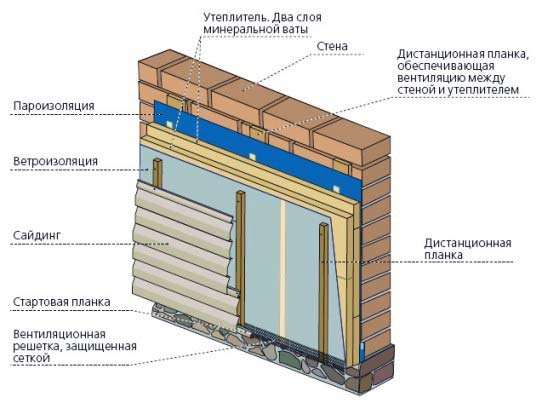

We fasten a heater

Siding performed after fixing the insulation. First, you should warm the walls of the building.

Perhaps this stage of work can be excluded, but we recommend not to avoid warming, because the heat in the house is coziness and comfort, as well as saving money on the consumption of natural resources. This is a pretty important point in the whole design.

So:

- In most cases, a mineral insulation or a basalt plate, which is a vapor-permeable material that does not harm the walls of the house, is laid between the main walls of the building and the metal frame. To protect the insulation from condensation and humidity, it must be placed between steam and water protection.

- First we need to apply a layer of waterproofing. To do this, we cut to the desired size and fasten using a construction stapler. In this case, an overlap should be made, not a joint;

- We make the fastening of the insulation. To do this, we use building fungi. First we make a hole with a perforator and after that we drive the fungus with a hammer. We make a connection of at least six points per square meter;

- If you make foam, then after installing it, the joints must be foamed with foam.

Panel Installation

The most difficult thing we have already done, relax a bit, however, keep in mind that the specifics during the installation of the panels are enough:

- At the bottom of each wall and directly to the windows, the starting elements are fixed, which are necessary to ensure a tight fit of the siding to the base of the house.

Attention: Consider one nuance, in the case when the length of the walls is greater than the maximum size of the siding strip, the installation of a connecting element will be required. I believe that you can cope without explanation - you just need to understand the need for its installation in an upright position.

- After the installation of all the corner elements is completed, you can begin to independently clad the building with siding. There is nothing complicated.

The panel measured in length will need to be inserted into the corner profiles and fixed to them using special metal screws. They can be distinguished from ordinary texes by the size of the cap - it is larger and has a corrugation at the bottom, so that the clip is reliable.

- I will focus on the clamp screws. The rate of thermal expansion and how it affects such a material should be considered.

When the siding panel is heated by the sun's rays, its size increases, so when the screws are fixed, screws will swell. To prevent this situation after the screw is screwed on, loosen it by half a turn to ensure free horizontal movement. - For the same reason, the siding panel should not fully enter the connection elements - there should be at least one centimeter between the panels and the ends on both sides. Thus, self-facing by siding will be done correctly.

- When attaching the screws, they should be placed in the middle of the groove. They are provided for this. This will save you from trouble during material expansion.

- When finishing windows and doors, a place should be provided for the installation of the facing panel.

And this work is done. Before starting its implementation, you should see photos and videos so as not to miss anything.

We buy material and get to work. Remember when buying, do not take components back to back. You will have at least 10% waste.