Cladding metal stairs or home decoration

In the modern design of country houses quite often there is not the last element of home decoration in the photo - a staircase. A house with more than one floor already implies this structural element.

To make the staircase as convenient, safe and comfortable as possible, the metal stairs are tiled with wood and tile. Today these are the most popular types of finishes for metal stairs, helping to make it more suitable for a given room decoration and creating a single composition.

The content of the article

Tile for stairs

An important point when choosing a tile as a finishing material is based on the possibility of facing almost any surface of a metal staircase. Whether it will be straight, screw, with transitions breaking straight sections, there is no difference if you know the finishing technology.

Violation of the order of the sequence of decoration can lead to poor quality results and not allow to obtain an aesthetic result.

Work order

So:

- Cladding stairs metal begins with laying the tiles below, when the first tile becomes a riser, then the first step, and the next riser.

- Only such a procedure for laying tiles will allow you to close all sections and remove trim edges from the eyes.

- This stacking sequence allows you to fill the cavity with an adhesive mixture as much as possible.

- Experts categorically object to the start of work on top of the stairs, although such cases are present in practice.

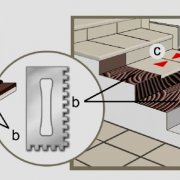

- The selection of adhesive mixtures affects the bond strength of the tile with the metal ladder and its service life.

- Special compositions used when working with tiles are calculated for facing unstable surfaces.

- The usual mixture can lead to displacement of the tile and its cracking, which will require the replacement of individual elements and repair of the stairs.

- In the video, the craftsmen say that in some cases, builders choose and use other fasteners. This class includes screws, special anchors, trims. They allow you to get high-quality cladding with a long service life, especially if you use natural stone such as marble, granite or other natural material.

Attention: During works on tiling staircases, it is necessary to provide places for passage. Until completely dry, stepping on the tiles is prohibited.

- Metal stairs are lined with rare and elegant stone materials, performed in the house or offices of companies that represent their reliability and wealth, because to make such a finish, considerable funds are needed.

- Natural stone has a small thickness of up to 1.5 cm and an average tile size of 30 x 30 cm.

- Cladding works are no different from the process of laying artificial tiles made of ceramics or porcelain.

- If tiles with significant weight are purchased, and work is performed from the sides of the flight of stairs, where there is no supporting surface, the tiles are additionally fixed with anchor fasteners.

- Specific conditions determine to make the anchor through and then mask the mounting holes with a solution to match the color of the stone, or glue on the back side with glue.

- Surprisingly easy, the expansion method of fastening in the form of plastic dowels, wedge or self-tightening anchors can split and spoil even a thick plate, so the instruction prohibits their use.

- Facing stairs is identical to ordinary work related to decoration, so the same tools, working methods, materials are used.

Stairs with wood trim

Metal staircase cladding with wooden products is completely different from the work done when facing the stairs with tiles. The absurd statement that a tree can not only give an unusual appearance to a staircase and a room, but also significantly increase the power, reliability and rigidity of a structure, has a basis under it.

Facing a metal staircase can be done in two ways, each of which deserves attention.

Work with wooden linings

So:

- The best option is to fasten the wooden trim below.

- Such a fixation of the tree allows you to remove even a hint of the visibility of the mount.

- The tree is fastened with special fasteners with screws or with cuts itself.

- To carry out work on fixing wooden elements from below, holes are drilled in metal steps in two rows.

- Between each other, the holes should be 20 cm from each other.

- 2-3 cm from the edge of the step, and a wooden pad is applied.

Attention: An important point in the selection of a wooden lining is its thickness, which should not be less than 30 cm.

- To fix the boards, special screw clamps are used on both sides.

- In the places of the holes made earlier, the wooden plate is drilled to the metal steps most often with self cuts.

- When the variant with a wooden lining from below cannot be performed, the wooden canvas is drilled from above.

- The board should again be fixed with clamps, and then drilled through the wood with metal.

- The diameter of the holes should be less than the screws used by 1-1.5 mm.

- Using a drill with a diameter of 6-7 mm, small recesses are drilled in existing holes of 7-10 mm.

- This is done to disguise the hats of the screw, here metal cuts are also used for fastening.

- After the canvas made of wood is attached to the metal step through.

- The holes are hidden with special furniture plugs.

- The plugs fit perfectly into the hole and fit very tightly to the hole, visually these places are practically invisible.

- An attractive appearance is given to the stairs by a small trifle of fastening the wooden canvas, it should go 2-3 cm beyond the steps.

- The edges of wooden linings are made smooth, without roughness and sharp corners.

- It is worth dwelling on the fact that not every tree can be suitable for facing a metal staircase, even if the price will fully correspond to your ideas.

- This is associated with various natural factors of wood, structure and its features.

- Oak, beech and hornbeam are among the hardwoods most suitable for cladding with a long service life.

- Any work of facing the stairs should be carried out in accordance with the rules and regulations using durable building materials.

Self-facing the stairs with wood

Decorating a metal staircase with wood allows you to solve two problems:

- A presentable appearance is given to the structure and its decorative properties are improved.

- Performance is much improved.

- To do it yourself, you need to stock up on wood for metal finishing.

- Joiner's tool and varnish.

- With screws, nails, self-cutting, fixing studs.

- You must have a level, a plumb line, a ruler.

- The design of the stairs is determined and one of the ways of sheathing a metal product is selected.

- Sheathing will be done with or without risers.

- View of wooden railings with balusters or metal roof rails.

- The design looks more representative if the welded frame is completely sewn up and there are completed wood trim elements.

- The upper part of the lining is selected from trees resistant to wear.

- Vertical gaps can be made between the steps of glued oak or other softer wood. Spruce or pine will look under carpets quite appropriate.

- Wood cladding It starts with the preparation of materials for cladding and is adjusted so that there are no gaps. To do this, all the wooden elements of the steps are measured and numbered.

- Handrails are offered to consumers with different sections, so you need to choose a comfortable shape for your hands.

- The balustrade, which also performs a protective function and spectacular staircase decoration, is selected depending on the design of the room.

Attention: A distance of at least 130 mm is selected for placing balusters on the stairs, provided the width of the steps is convenient.

- With screws, the upper part of the step is fixed after the installation of wooden elements.

- Prisoners pressed tightly to the frame are also fixed, similar work is performed along the entire length.

- Balusters and columns are located from beginning to end along the edges.

- It is mandatory to check their vertical installation.

- Railings are installed on the elements fixed with special studs.

- The frame is completely sewn. A wooden panel covers the side of the stairs, repeating the shape of the steps.

- Finishing metal marches on the back of the structure is carried out with the same panels or sheets of drywall.

- Work is performed immediately after the steps and risers are ready.

All wood inserts and elements are varnished, give time for the structure to dry out well. Projects of marching stairs for individual cottages and houses are in the same category with all the stairs and do not differ in any special conditions.

A good result can be obtained using furniture fasteners for attaching wooden steps. In order not to drill through the steps, you can screw furniture couplings into them from below. This product is in the form of a barrel, on the outside of which there is a large thread (it holds securely in a tree), and inside there is a metric thread for a bolt or screw. The coupling is twisted into a tree with a slotted screwdriver or hexagon, and then, the steps are attached to the stairs with ordinary screws.