Brick chimney lining: design options

There are many ways to design a chimney at home, but the most common is brick lining of chimneys.

The content of the article

Types of brick for facing the chimney

In the modern construction industry, various types of materials are used.

At the moment, facing the chimney with a brick can be performed:

- Ceramic brick.

- Silicate.

- Hyperpressed.

- Clinker.

Note. All of them can be full-bodied or hollow.

Hollow facing brick has good thermal insulation properties. He is able to protect the chimney from freezing.

Ceramic brick and its properties

This type of brick has its advantages. As a rule, it is hollow, which makes it possible not to create additional load on the roof when using it. But the holes in such a brick can be different.

Tip.

All professionals recommend the use of ceramic bricks with small sections, since the application area for the installation of the material will be larger. From this, a bond of brick and concrete mortar will be better.

Characteristics:

- It is made from clay dough, which is pressed under the influence of high temperatures and only then burned. There are various designs of such material in the design of the chimney (seeFinishing the chimney outside and inside the house) it is possible not to use one tone of brick.

To do this, there are a variety of masonry materials that are used not only on chimneys, but also on any surface. - The price for this type of brick is several times more expensive than for other types. This is due to the complex technology of manufacturing the material.

- Ceramic brick can be single or one and a half. The size of a single brick is 250x120x60 mm, and one and a half - 250x120x88 cm.

- There are not only rectilinear brick shapes, but also with rounded corners. Thanks to this, it is possible to create an interesting design of the chimney, which for this reason can take rounded shapes.

- The most popular were white and red ceramic bricks. The second place belongs to yellow and brown.

Tip. In the process of laying ceramic bricks, you can use the "layout".

What it is? This masonry is carried out under a colored seam.

That is, using a special gun, a colored concrete solution is applied to the joints. You can save time and money and directly into the concrete solution, with which the masonry is carried out, add a pigment of a certain shade.

Silicate brick in the chimney lining

Brick cladding silicate chimney is performed quite often. This type of material has a perfectly smooth surface and a wide range of shades.

It has excellent technical properties and characteristics.

Tip. In some cases, salt may appear on the surface of the silicate brick, and in order to get rid of it, it will be necessary to clean the surface with an acetic solution or a damp rag.

The surface of this type of brick can be:

- Flat.

- Textural.

- Embossed.

- Grungy.

There are differences in strength and frost resistance, and in other individual technical characteristics. Silicate brick itself is an autoclave material in which a variety of hardeners are added.

After this, the mixture is poured into special forms and exposed to high temperatures.

Hyperpressed brick for facing the chimney

Overpressed facing brick for a chimney differs from all other types not only in its dense structure, but also in the technology of its manufacture.

Today, this type of brick has become quite popular. There is a wide range of sizes and surface finishes.

Hyperpressed brick has a surface:

- Smooth.

- Rough

- Structural.

- In some cases there is a glazed surface.

Material Features:

- You can use such material not only for finishing a chimney or wall surface. Quite often, hyper pressed brick is used to garden path finishes.

- Its cost is not too low, but this does not reduce the popularity of the material and its technical characteristics.

- There is a standard size: 250x120x65 mm, and there is a non-standard "American" 250x60x65 mm. It can also be hollow.

Brick cladding brick

This type of brick for facing the chimney is distinguished by its high strength and density. It is made under the influence of high temperature.

Characteristics:

- It is worth noting that a chimney made of clinker cladding brick has excellent properties. Throughout the entire life of the structure, it does not lose its appearance and not its functionality.

- There is a wide variety of shades of material. Aged clinker brick became popular. With it, you can create the original design of any design.

- The dimensions of such a brick are 240x115x71 mm. There are not only rectilinear forms of the material, but also round ones.

Clinker brick surface can be:

- Smooth.

- Grungy.

- Structural.

- Embossed.

- Glazed.

- Shabby.

Glazed clinker brick can be on all sides of the same design or only on one specific side, which will be front in decoration. From this, the cost of the material also differs for this reason.

Properties and characteristics of facing bricks

Cladding brick has excellent properties and characteristics.

Is he:

- Durable and reliable, as it can withstand not only its own loads, but also additional physical and mechanical stresses.

- Practical, its surface does not require special care and cleaning. The most important thing is to correctly and accurately make the masonry of the material.

- Moisture-resistant, the surface of the facing brick, regardless of its quality, is not able to absorb moisture and dirt, dust.

- Fire-resistant, the material does not burn and does not melt under the influence of high temperature conditions.

- It is not exposed to a variety of temperature conditions.

- Frost-resistant, withstands low temperatures in the cold season and does not deform.

- Wear-resistant, throughout the entire period of use of the cladding does not change its structure and appearance.

The life of the facing brick, depending on the type, is in the range of 25-50 years, but this does not mean that after this period the structure and properties of the material will immediately decrease. All this happens gradually.

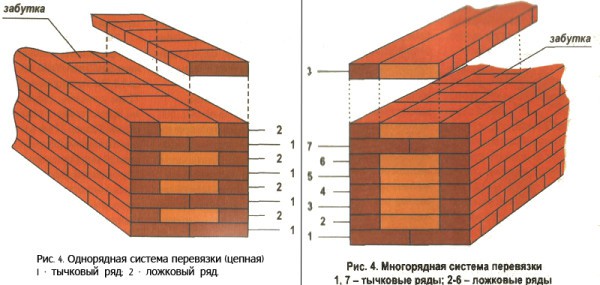

Types of masonry facing brick for the chimney

There are several options for laying brick for the construction of a chimney. For each of them there is a specific instruction, according to which all actions are performed to create an ornament and the laying process itself.

Types of brickwork in the chimney:

- "Blocky".

- "Cross".

- "Track".

- "Gothic."

- "Savage."

- Brandenburg

More details:

- The “block” masonry is characterized by the fact that it contains alternating long and short brick elements. That is, the process is carried out with the installation of the whole brick and its half, and in this way it is worth paying attention to the dressing of the material.

- The "cross" masonry is very similar in principle to the "block" one. But there is the possibility of displacement of the halves of bricks over the entire surface of the wall. They cross with whole bricks.

- The “path” is characterized by using only the long sides of the brick. during masonry they can be shifted to the sides.

- The “Gothic” masonry has alternating the long and short sides of the brick on the surface. In some cases, such alternations are distinguished by material of a different shade, and due to this, an original design is created.

- "Savage" is characterized by the alternation of the short and long sides of the brick to the masonry.

Only this alternation is uneven, but chaotic. Using this masonry, it is also possible to create an original design of the chimney. - The “Brandenburg” masonry consists of two long sides of a brick, which alternate with one short. There is a change in each brick row with the arrangement of elements.

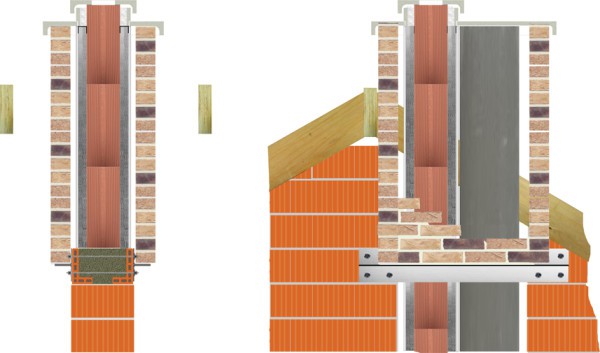

Installation of a chimney from a facing brick

Facing brick chimney is independently mounted quite simply. Only for this you need to make the design correctly.

What is she like?

You need to know the specific height and width of the chimney. It is also worth considering that a fluff is made at the beginning of the chimney and at the top, that is, the base and end of the structure itself differ in size and width from the middle.

Tip. The height of the chimney must be optimal and it is calculated based on the climatic conditions of the region.

All actions are easily performed with your own hands and without the help of specialists in this field, for work you will need:

- Mortar concrete.

- Capacity for its mixing or concrete mixer.

- Plumb line.

- Pickaxe for cracking or undermining bricks.

- High strength cords.

- Building level.

- Bulgarian.

The video shows the process of installing the facing brick in the chimney.

Tip. Before starting work on laying brick facing, it is worth consulting with professional builders, who in this process may know some nuances.

It is also worth considering that in some cases, an asbestos solution is used for laying the chimney, which does not burn and does not deform under the influence of high temperature conditions. If there are separate pipes in the chimney, then the distance between them and the brickwork should be filled with insulating material.