Drywall estimate: advice from the masters

Today, drywall is used in almost all finishing and repair work. It is considered universal, as it has excellent technical characteristics.

Drywall consumption for cladding may depend on some parameters of the room itself.

The content of the article

What is drywall and its varieties

Drywall appeared relatively recently. But, despite this, it has already become very popular among repairmen and builders.

It consists of several layers:

- A sheet of thick cardboard.

- Plaster dough with various additives.

- A sheet of dense drywall.

Note. Due to this structure, the material is distinguished by its strength and practicality. Gypsum dough itself is quite fragile, but sheets of dense pressed cardboard do not allow it to dry out and crumble.

At the moment there are several types of such material:

- Wall.

- Ceiling.

- Arched.

The dimensions of the drywall sheets also have differences, there are:

- 1,50x2 m.

- 2x2 m.

- 2.20x2 m.

Material Details:

- Consumption at wall cladding drywall depends on such parameters.

- The thickness of the wall drywall is different from the ceiling. The latter type of material is not too thick, since it is used to decorate the ceiling, and the size of the drywall and its thickness affect its mass.

- Arched drywall has a perforated structure. This is necessary in order to freely give the material the necessary shape. This type of drywall is quite light and quite often you can find it on the surface of the wall as a decoration.

- Under the surface of such material place various lighting devices. You can also use arched drywall to make partitions to divide the space into functional zones.

Technical properties and indicators of drywall

At the moment there is a moisture-proof and fire-resistant drywall. Estimation of wall cladding with drywall implies clarification of the use of one or another type of material.

Drywall is quite durable, since it can withstand significant mechanical and physical effects on its surface. It is very practical, since it does not require special knowledge in its installation.

There are several types of finishes for this material:

- Plastering.

- Coloring.

- Pasting.

So:

- Can be used on the surface of drywall natural stone or artificial, ceramic or glass mosaic and so on.

- Drywall life is at least 15-20 years, but it all depends on the type of material. Due to the properties of the material, you can create a unique design for both wall and ceiling surfaces.

- The price of drywall depends on its type. If it combines fire resistance and moisture resistance, then the cost of the material will be high.

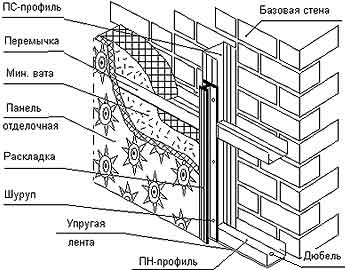

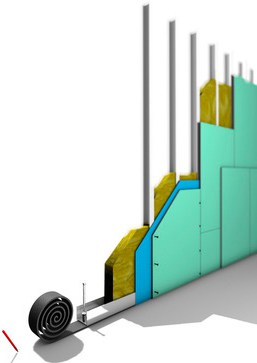

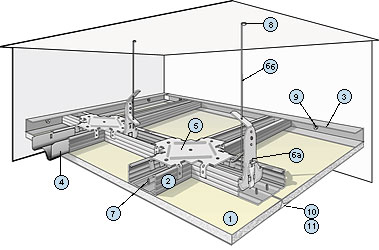

Drywall is mounted on a metal profile frame, the calculation of which is also included in the consumption of materials for facing wall surfaces.

Why gypsum board is chosen in repair work

The main advantage of drywall, both wall and ceiling is a fairly quick installation.With the help of such works, it is possible to level the surface very easily, especially if it has large defects.

Material Features:

- After working with drywall, there is not much construction waste left, as from the use of plaster. As a result, the surface is perfectly flat and can be finished on it.

Tip. It is better to use drywall in those rooms that are quite spacious.

This is due to the fact that the frame on which the material is mounted has its height from the surface and it depends on the size of the defects. As a rule, the minimum height is 5 cm.

- Also in the decoration it is worth considering the thickness of drywall, which is mounted on a metal frame.

Due to the versatility of the material, it is possible not only to create multilevel structures on the ceiling, but also on the wall.

How to make an estimate for the decoration of gypsum plasterboard walls

Drywall cladding calculation does not require specific knowledge in the field of mathematics or geometry. It will be enough to know how the quadrature of the room is calculated.

It takes into account:

- The height of the room.

- It is long.

- Width.

Tip.

You need to measure the room not only in the corners, but also around the entire perimeter, since there can be different indicators of such parameters. This is especially necessary to take into account in houses of the old construction, where the difference in ceiling height is quite large.

- For measurements, a tape measure, a pencil and a simple blank sheet are used, on which all sizes are recorded.

Tip. If the room has door and window openings, then their parameters are subtracted from the overall dimensions. You will also need to know exactly their width, height and length in order to correctly calculate the quadrature.

Wall cladding with drywall consumption profiles for the manufacture of the frame should also be taken into account.

There are several types of such devices:

- Profile guides.

- Rack.

So:

- Both those and those have a length of 3 m. The diameter of the profile for the consumption of material does not play any role.

- To correctly calculate the required number of profiles, you need to approximately draw their location on the wall surface. The distance between them should not exceed 70-80 cm.

Only in this way it will be possible to qualitatively fix drywall on them.

Tip. Even if the ceiling height is only 2.5 m, then 3 m is taken into account. The remaining element of 50 cm can be used for the manufacture of crates.

A similar calculation is made if the length of the room is not 6 m, but less. That is, profiles are always taken with a margin.

- Next, the width and length of the drywall sheets are taken into account. As a rule, they need to take an even number on each wall.

- The consumption of gypsum plasterboard wall lining may also depend on various kinds of structures on the surface.

- For example, it has become very popular to depict convex flowers on the walls, which with the help of mounted lighting devices create a unique design for any room.

After all such work, an estimate is made for gypsum plasterboard lining, it includes:

- The number of sheets of material.

- The number of profiles, both rack and rail.

- The number of dowels and screws. This indicator during installation of drywall can vary.

Tip. Self-tapping screws and dowels for mounting material are always bought with a margin. Calculate their exact number will not work.

Plasterboard surface mounting

After the materials are purchased in the prescribed amount, you can safely proceed with the installation of drywall. For this, preparatory work is carried out on the surface.

All work of this type is done by hand, it includes:

- Peeling surface of exfoliated plaster or paint.

- Cleaning with detergents (abrasive or mild).

Tip.Such work is very necessary for the reason that if there are certain contaminants on the surface, then fungal diseases can form that will adversely affect human health, although they will not appear on the surface of the fine finish soon.

- Padding. This process includes surface treatment with special antifungal agents.

Tip. If additional lighting is planned on the wall, then all electrical wiring is laid before installation of the material.

Mounting a metal frame

Instructions for such work do not exist. The metal frame is assembled on the surface according to the principle of manufacturing a lath for the installation of a plastic lining.

For this you need:

- Rack profile.

- Profile guides.

- Construction level and tape measure.

- Dowels for fixing on the surface of the frame.

- Self-tapping screws for fastening together elements of a frame structure.

- Drill for screwing dowels and a hammer.

- Screwdriver for using self-tapping screws. When using a specific nozzle, it can be replaced with a drill.

- Hacksaw or scissors for metal.

Initially, guide profiles are mounted and rack-mounted are already attached to them. The frame itself is not subjected to additional processing, as profiles are made of stainless steel, which is not exposed to a humid environment and various fungal diseases.

Installation of drywall sheets on a metal frame

As soon as a profile metal frame is ready on the surface, it can be considered that half of the drywall installation work has already been completed.

To mount sheets of material on it you will need:

- Self-tapping screws and screwdriver.

- Tape measure, pencil and building level.

- Clerical knife, since drywall is quite easy for them to cut.

- Putty and special construction tape for gluing joints.

Tip. If the size of the room allows, it is better to mount drywall sheets intact. This will save time on finishing joints of the material.

Better to do the work together. The sheet initially exposes in level and only then is fixed.

After the installation is completed, all drywall joints are glued with tape and putty. Then they are processed with sandpaper. Now the sheets are ready for finishing.

The video shows an example of installing drywall on a wall surface using a metal profile frame. There is nothing complicated in the work.