Snip-finishing: what is it for

What is snip decoration?

This is a system of norms and rules for the execution of finishing work indoors. That is, to carry out any decoration has its own established standards.

The content of the article

What is SNiP for?

SNiP is a document that is established by special organizations, which contains all the rules for the repair and construction work of any room.

Note. Each type of work has its own set of specific rules for their implementation. The code also indicates all acceptable materials for repair and construction.

What work on interior decoration is provided by SNiP

The interior decoration of the SNP premises provides for:

- Rough finish.

- Fair

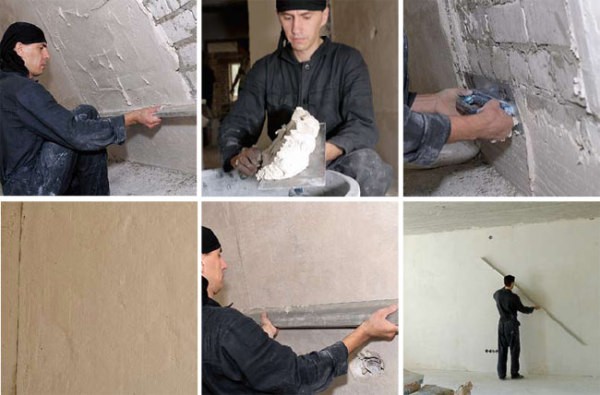

The photo shows examples of such works. They differ in their execution methods and in the materials used in the work.

Tip. All work that is carried out in accordance with SNiP must be of high quality, since all norms and quantities of the material used are observed. In case of violation of such standards, the finish will not serve for a long period of time and the work itself is of poor quality performance.

Interior decoration rule

SNiP interior decoration provides for the implementation of such norms and rules:

- All indoor work should only be carried out at a certain temperature. It should be at least +10 degrees.

At the same time, the humidity inside the room is also taken into account, which should be no more than 60%.

Tip. Such conditions in the room should be during the day before finishing work and after their completion within 12-15 days. Thus, the finish is firmly fixed to the surface.

Also, work is performed in accordance with the temperature regime:

- At +10 - when using paint or other means of paint and varnish production, mastic or putty, when gluing the surface, when using polystyrene and so on.

- At +15 - when using polymer concrete and other similar material, sealants, synthetic finishes, polymer metal coatings, and so on.

The work is carried out in this way and in the sequence as specified in the design of the work.

Tip. Snip interior decoration of residential premises provides for the implementation of a series of preparatory actions.

- Initially, atmospheric protection of rooms against the effects of weather and climate is done. High-quality insulation must be carried out: heat, sound, waterproofing.

- All screeds are preliminarily carried out on the floor surface with a specific order of building insulation. All seams and joints of masonry building materials are well sealed and special tools are used for this.

- Window and doorways also be prepared. Their surface is treated and insulated. Such work is necessary in order for the glazing of these structures to be performed efficiently and the door to be mounted correctly.

- All lighting, heating, water supply and other communications systems that are necessary for a normal life in the house have been carried out.

Tip. Surface plastering when planning communications systems in a building should be carried out previously.

Rules for performing rough work on the surface for interior decoration

Snip roughing is done according to established rules.

Tip. In order for the fine finish to be performed efficiently, the roughing is performed on the surface also well.

The first thing to do on the surface is to clean it.

The process of such work includes:

- Elimination of rust on the surface.

- Chipping plaster from a surface that has already moved away from it.

- Removing the paint layer.

- Removing wallpaper and other adhesive material from the surface.

- Disinfection of the surface in order to protect the premises from the formation of mold, which can serve as a source of human diseases, and when using certain materials, protect them from harmful effects and prevent the destruction of their structure.

- Cleansing. This is done with detergents and cleaners that treat the surface with foam or metal brushes.

- Primer surface.

Tip. Recent work is carried out only after the surface has dried well after wet exposure.

- All work of this type is quite simple and do it yourself. To eliminate rust, use special tools that treat the surface.

It will be mandatory to continue to apply to the surface and those places where the asbestos solution was rust. - If there is mold on the surface, then you can not do without chlorine-containing agents in processing. Special solutions are also applied that are applied to the surface.

Tip. When using such tools, safety standards must be observed. Rubber gloves are put on the hands and a respirator on the face.

Washing paint or varnish from the surface is performed by a certain means. To apply correctly there is an instruction.

According to it, it indicates how many layers of the product, and what size is applied to the surface. What kind of work is done after that.

What else is included in the rough finish

Also in the rough finish includes:

- When choosing drywall - production of a profile frame.

- When choosing paint, decorative plaster and other finishing materials - leveling the surface.

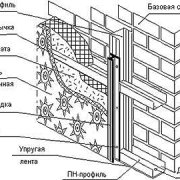

Note. According to the rules and regulations, the frame for drywall is made directly on the surface, and only special stainless steel profiles are used for it. The way they are installed depends on the type of surface.

For work, you need a tool for cutting metal. It can be a grinder or a hacksaw, scissors for metal.

Also required:

- Construction level and tape measure for smooth installation on the surface of the metal frame.

- Dowels that attach the frame to any surface. The size of this mount depends on the quality of the wall.

If the wall is made of wood, then a small dowel foot will do. If the wall is made of bricks, shells or other building blocks, then longer legs of screws and sometimes with keys are used to securely fix the frame.

Tip. According to the rules and regulations, surface leveling can also be carried out with plasterboard sheets. The installation process of the frame is similar.

You can even the surface with:

- Concrete mortar.

- Plasters.

- Another roughing preparation.

So:

- The consistency of the solutions depends on the quality of the material from which the wall is built. For better performance, two types of plaster are used: “start” and “finish”.

Only start plaster is used immediately on the surface. Then, layers of finishing plaster are applied to it.

Tip. Preliminary surface undergoes preparatory work.

- Concrete mortar is also prepared according to established standards. It is necessary to observe the proportions of raw materials: 1 to 3.

That is, for one standard bucket of cement 3 similar buckets with sand are used. Water is added already until a certain viscosity of the solution is reached. - Which is better to choose: concrete mortar or plaster, drywall? The easiest way is to level the surfaces with drywall. The price of such material is low.

Tip. It is impossible to level the surface of the floor with drywall, since any fairly significant impact on the material can serve as a deformation of the gypsum dough inside the drywall.

- For application, a solution of concrete or plaster will require a special tool: a spatula.

Tip. For such work it is better to invite a professional.

- In Snip there is also a number of rows of plaster, which will be optimal and their thickness. Each layer should not exceed a few millimeters.

They can be applied: starting - up to 5-7 pieces, finishing - 2.3 layers. It also indicates what quality sandpaper should be for processing the start or finish layer.

Tip. Priming with plasterboard and plastered surfaces will be mandatory.

Finishing and the norm of its implementation

Interior decoration SNP depends on which materials are selected for work.

Here, the skill of the repairman and how he can perform these or other finishing work plays a large role.

So:

- There are rules for using each material. For example, to use wallpaper, the surface must be not only smooth and primed, but also cleaned.

Depending on what exactly the wallpaper is made of, they select the means for gluing them.

Tip. If the glue for wallpaper is not selected correctly, then there is a risk that the wallpaper will eventually move away from the surface and thereby spoil the exterior design of the room.

- If paint is used, the choice of such a tool depends on the quality of the surface and the humidity in the room. The methods of applying paint are quite diverse, but the use of brushes and rollers is considered universal.

Tip. According to some rules and regulations, applying several colors with such tools is not recommended.

- When using plaster, restrictions are also set in the choice of tools and the number of layers of the product. It all depends on the surface on which the plaster is applied.

The use of other decorative finishing materials is described in each separate article.

It is only worth considering that for using any of their kind, the surface is also prepared, and the necessary tools are selected. The video shows an example of the implementation of draft and finishing of the premises.

I really needed SNIP to refer to it in the contract in the section on the description of the quality of work. When compiling technical specifications, SNIPs are also useful. If memory serves me right, although they are normative acts, until the technical regulations have been adopted, it is better to clarify in advance if SNIP is not a normative act, refer to it in the contract when describing the required quality of work. By the way, it is possible to establish exemptions from the requirements of the SNIP (more stringent requirements, for example), but it is by specifying this in the contract or the terms of reference.