Compressor for painting: what to look for when choosing

Even 30 years ago, pneumatic spray guns were available only in factories and large factories. Compressors of that time were distinguished by their enormous size and incredible noise level, and besides, they required a connection to an industrial electrical network of 380 volts.

A modern paint compressor has become much more compact, and at the same time it has practically not lost in power. But the question arose of how to choose it correctly, especially if you take into account the huge number of manufacturers represented in any hardware store, and this is what we will talk about in this article.

The content of the article

What you need to know about compressors

At first glance, all compressors may seem the same, but why then do they have such a phenomenal price difference? The price of a compressor depends on many factors, and it is selected depending on how you use it.

It is not always advisable to take the most powerful equipment, especially if you are not going to work with it constantly. Below we will look at several popular models in the price range of up to 10,000 rubles, which are ideal for painting even as thick as hammer paint.

But before talking about specific models, let's look at the main characteristics that directly affect the cost of the compressor for painting:

- Receiver volume. Depending on the model, it can be either very small, with a volume of 5 liters, or huge, with a volume of up to half a ton. The size of the receiver affects how intensively you use the compressor. The more air you spend, the more the receiver should be in order to reduce the load on the engine.

- Number of working cylinders. There can be from one to four. The more cylinders the compressor has, the faster it pumps air into the receiver. 4 cylinders are mainly used on industrial equipment, and the compressors we are talking about have 1 or 2 cylinders and this is quite enough for uninterrupted operation at maximum load.

- Electric motor power. Household compressors operate on a normal network and do not require a special connection. Engine power can be from 0.5 to 3 kilowatts, and you should choose it based on how often you use this equipment and what maximum loads you intend to use.

- Maximum working pressure. For different models, it can range from two to 12 atmospheric units. This indicator affects what paints you use in your work. The thinner the paint, the less pressure is required to spray it. For example, for water-based paint two atmospheres are enough, and at least 8 will be required to spray the hammer enamel.

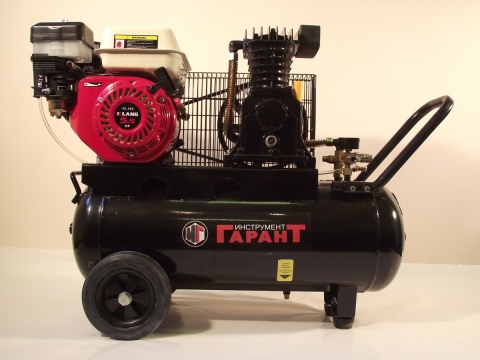

- Mobility. The smallest compressors can be easily carried on hand, while others require stationary installation. The equipment we are talking about can be moved with the help of small wheels. Such a compressor is easy to move from place to place and does not require a permanent location.

So, we figured out the basic characteristics, but when choosing a quality tool, they will help a little. There are a lot of manufacturers of equipment, but almost everyone has the same set of problems that one way or another appear during operation.

And before proceeding to the description of defects. We recommend that you watch the video in this article, which shows how to paint with a compressor.

The main causes of compressor failure

The main reason for compressor failure is the incorrect calculation of power and load. A universal formula does not exist, since all paints have their own characteristics of density and viscosity, in addition, each master paints the paints independently.

Important! The optimal compressor operation cycle is 5 after 2. That is, after working for five minutes, the compressor needs at least two minutes of rest.

The frequency of turning the compressor on and off depends on all the factors listed above at the same time. It is important to consider what type of painting is more characteristic for you. If you often paint smooth surfaces, that is, the tool works by constantly pressing the lever of the spray gun, it is advisable to select a tool with a large number of cylinders and the size of the receiver.

An electric motor may also fail if the load is increased, but burnout of the compression valves becomes a more frequent breakdown. They are tongues made of thin steel, which rise when the cylinder moves up and down after air intake.

The more intensive the compressor runs, the more these tabs heat up and at one point simply stop working. In this case, the engine will continue to rotate, and the cylinders will move, but there will be no compression in the receiver.

Also, air supply valves often fail, as they are used very often. When buying a compressor, be sure to pay attention to the quality of the valves. First, they must be fully brass or bronze. And secondly, the rotary handle should not be made of silumin or plastic, these materials quickly break down with frequent use.

In addition, many users often forget about the need to monitor the oil level in the gearbox, which tends to evaporate. Check the level regularly and supplement it if necessary.

Important! Do not use foreign oil to fill the compressor gearbox. Each manufacturer of equipment, as a rule, lets in its own oil, but if it is not, you can use a special compression oil, which is characterized by low viscosity.

Most problems can be fixed with your own hands, but only if your tool has already been removed from warranty service. Otherwise, it’s better not to go inside and entrust this work to professionals who are required to fix everything in the shortest possible time and completely free of charge.

Terms of Use

The price and brand of the compressor are not the key to its long and perfect service. A lot of envy on how correctly you exploit it.

There are several rules, observing which it will be possible to significantly extend the life of even the most inexpensive compressor:

- Always check the gearbox oil level. Each compressor specifically for this has a small window with labels. Do not let the level fall below a critical line, but do not overfill, as the excess will begin to fill the cylinders and oil can get into the air hoses.

- Constantly monitor the status of filters. Compressors take air from the outside, so the filters clog up very quickly, especially if you are working indoors. As a rule, the cheapest rag filters are installed for sale, which become unusable in just a couple of weeks, so it is better to immediately replace them with felt or something like that.

- If during operation you notice that the compressor does not turn off for quite some time, stop operation and allow the instrument to rest. Overheating of working units significantly reduces the operating life.

- Do not leave the compressor in freezing temperatures. At sub-zero temperatures, the oil in the gearbox begins to thicken, and the engine takes extra effort to crank out the viscous fluid. This creates a significant load on the rotor, and the engine can simply burn out. If the oil is still thickened, take the compressor to heat and let it warm up, after which it can be operated in the cold. During operation, the oil warms up on its own.

- Adjust the outlet pressure separately for each type of paint.. The less load on the engine, the better. For example, two atmospheric units are sufficient for nitro enamels or water-based paints, and there is no point in using a maximum of 12 atmospheres.

- Drain condensate regularly from the compressor. For this, a special drain hole is provided at the bottom of the receiver. Condensate always builds up inside when the temperature changes and when enough is collected, it begins to flow into the air hoses and mixes with the paint. The result is not spray paint, but spray paint.

Observing these simple rules, an electric compressor for painting will serve you faithfully for many years, even if it does not belong to the family of well-known brands.

Popular models

A compressor for painting is not a cheap thing, and the price of some models can reach several tens of thousands. This is often the price of a famous brand. Yes, such models are of high quality and long-term operation, but it does not always make sense to take such a technique, especially if you only use this tool from time to time.

For convenience, we will present you several popular compressor models in the form of a visual table. We will not give their value here, since it can fluctuate significantly, but we selected only those models whose price does not exceed 10 thousand rubles.

| Model | Characteristics | ||||

| Producing country | Number of cylinders | Working power (atmospheric units) | Productivity (liters per hour) | Receiver volume (liters) | |

| China | 1 | 8 | 180 | 12.5 | |

| China | 2 | 8 | 160 | 24 | |

| Russia | 1 | 8 | 198 | 24 | |

| Russia | 1 | 8 | 260 | 24 | |

| Germany | 2 | 12 | 260 | 30 | |

| Russia | 1 | 6 | 160 | 16 | |

All the compressors listed in the table received the most positive reviews from consumers, and most importantly, these models are repaired at any service center.

Which model to choose, you decide, and if you need only a one-time job, then think about the fact that there is such a thing as a rental compressor for painting. Often, it is better and more profitable to use a lease than to buy an instrument, and the cost per day of operation will not exceed a couple of thousand rubles.