How to choose the right gun for painting walls

Painting walls is a laborious and lengthy task, even if you are working not with a brush, but with a paint roller. Fortunately, the technology does not stand still, and today you can use the bullet machine. Even 20 years ago, such equipment was available exclusively in factories, but today you can choose an inexpensive tool that can easily cope with repairs in your home.

In this article we will tell you what are and how to choose the right bullet machine for painting walls, and we will reveal the secret of the phenomenal difference in price between different tools.

The content of the article

Types of spray guns

All machine guns can be divided into three types according to the principle of the driving force used in them:

- Manual(cm.How to choose a manual spray gun) A tool that does not have electrical elements and works exclusively at the pressure that the pump will create

- Mechanical. A piston works here as a supercharger, which immediately pushes the paint. Due to the lack of a storage receiver, the power of the instrument is very small.

- Pneumatic. Air is pumped into the receiver of a large volume, and already there is created the necessary pressure to raise and spray paint.

The most optimal, but at the same time, and expensive is considered a spray gun with a pneumatic drive. With it, you can work even with the thickest dyes.

This is not the case with hand-held models that can spray only the most liquid paint. In order not to take away a lot of time from the reader, let's immediately turn to a detailed description of each option.

Manual spray gun

Most often it is used as a bullet machine for water-based paint, since it has a liquid consistency, and it will not take much effort to spray it.

Outwardly, it is a container into which paint is poured, equipped with a pump and a spray hose. Paint is poured into the tank and pressure is created using the pump. One pumping is enough for about five minutes of work, then you need to pump it again. This unit has no advantages, but there are plenty of disadvantages.

To enumerate all of them, not a single similar article will be needed, so we will focus only on the most significant ones:

- Low working power. Work with any more or less hard or thick materials is no longer possible.

- Low speed. The efficiency of this tool is almost zero, since you have to constantly maintain the pressure inside the tank instead of painting.

- The layer of paint applied with a manual spray gun is unevenAs a result, gaps, necroses and sagging may appear on the surface.

- Inability to adjust working pressure, air stream and spray intensity.

- Paint the ceiling with such a tool is very difficult, since the pressure in the buoy is not enough to raise the paint to a height.

As you can see, there are a lot of shortcomings, so you can buy such a tool for only one purpose - to whiten the walls somewhere in the garage or basement. For more serious work, you have to look for a better model.

Electromechanical bullet machine

This gun for painting is used much more often than its manual counterpart, although it is not very popular. It’s all about the same power, the supply of which is enough for the instrument to only slightly spray PF 115 paint. An electric motor inserted into a compact hand tool is simply not capable of delivering more, otherwise its weight would have increased significantly.

Of the advantages, one can distinguish the relatively low cost of the tool and its compactness. In principle, if you need to make repairs in one or several rooms, and you do not plan to use it constantly, then you can choose this option. But for professional work, he is no longer suitable.

We will not describe the working process in detail using an electromechanical spray gun, so we just suggest that you watch the video in this article, and detailed instructions for handling the tool are always on its packaging.

Pneumatic bullet machine

The most common and effective paint gun. Able to work with any materials, regardless of their consistency.

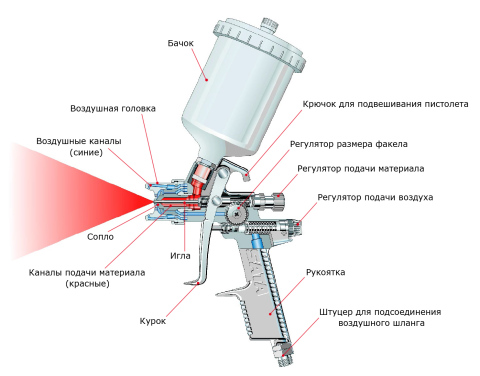

The tool consists of two main components:

- Compressor. An electric motor pumps air into the receiver, and from there it enters the spray gun itself.

- The bullet machine itself. A complex mechanism with a tank in which the paint is placed. Air is supplied to the gun through a hose and, mixing with the paint, it is sprayed.

Based on the design, it can be understood that the power of a pneumatic spray gun directly depends on the size of the receiver’s balloon, and on how quickly the engine can fill it with air. Pressure is regulated according to the consistency of the paint, so you can work with any material.

In addition to these tools, there are also specialized bulletiners for working with powder paints. Their fundamental difference from conventional pneumatic models is that current is supplied to the nozzle, as well as to the product to be painted. As a result of the collision of charged paint particles with the surface, adhesion occurs at the molecular level.

Powder coating is considered the most durable and durable, but it can only be applied in a specially equipped workshop, so we will not focus on this tool.

So, summing up the intermediate results, we note that the most effective option is a pneumatic spray gun. Its only drawback is the price. But it does not always make sense to buy such equipment. Sometimes an ordinary hand tool is enough.

So, we will consider all the spray guns described above in the form of a small visual table:

| Specifications | Types of spray guns | ||

| Manual | Electric | Pneumatic | |

| Power | Low | Average | High |

| Spray power | Low | Average | High |

| Jet size | Any. Unregulated | Wide | Adjustable |

| Heap | Low | Low | High |

| Paint density | Liquid | Average | Any |

| Ease of use | Uncomfortable | Uncomfortable | Conveniently |

How to paint the walls

So, we decided on the choice of tool, and it's time to talk about how to paint with a bullet machine. After all, we are talking about working with our own hands, and this requires experience. If it is not there, then this section of our article will help.

First of all, regardless of what kind of paint you work, it must be thoroughly mixed. Make it a solid object with a broad base so that it reaches the bottom.The fact is that as a result of long-term storage in the store, the paint settles to the bottom, and only the binder component remains on the surface.

Next, the paint is diluted to the required consistency. Before you dilute the paint for the bullet machine, you need to decide which tool you are working with. If you have a pneumatic spray gun, then you need to dilute the paint only slightly, that it was not lumpy. But for an electric tool you have to make a more fluid consistency.

Important! If you use tinting paste, then pour all the paint into one large container and only after that give the paint a color. If you do this for each jar separately, then you are unlikely to succeed in achieving the same shade in all containers.

Now you need to clean the surface of dust and debris, as well as remove grease stains, if any. They can cause poor adhesion of the paint to the surface. Moreover, she may begin to change color in this place.

Next comes a layer of impregnation or soil. This also should not be neglected, since the walls are a fertile environment for the development of mold spores, especially if there are cold bridges on it. So, the surface is ready, and it's time to cook our tool.

First of all, it is necessary to blow out a spray gun with a solvent of the brand that you plan to paint. The fact is that particles of another, conflicting solvent may remain inside the container, and this will lead to coagulation of the paint in the tank.

Advice! Always use only the solvent with which this paint is diluted to flush the spray gun. Otherwise, the curled residue will clog the nozzle, and you will have to completely disassemble and clean the tool.

Now we pour the paint into the container, and on the foreign object we try to apply the first layer. Never start working right away without preparation. On the "draft" you can adjust the direction, speed and power of the inkjet, as well as find out the optimal distance of the spray gun from the surface so that smudges do not form on it.

Everything, you are ready, and you can take up the finishing work. Start painting from above, and gradually go down. This will help to avoid smudges, and allow you to see all the unvarnished places.

Well, so we figured out how to paint with a bullet machine. As you can see, the main difficulty lies not even in choosing a paint or application method, but in choosing the right tool. It is from this that the whole quality of work will largely depend.