How to make a homemade spray gun: manufacturing steps

Do-it-yourself homemade airbrush is not so difficult. And if you have a lot of paint work, then you will save on the purchase. How to make a homemade airbrush at home, we will consider today.

After all, there are several options and it will be necessary to choose the right option. Videos and photos will help you make the right choice.

The content of the article

DIY spray gun: the main advantages

For any painting work, you can use a simple homemade spray gun, which will provide you with additional benefits than a regular roller (seePaint rollers: consider in detail) At the same time, to save money, the tool can make a homemade spray gun for painting.

Strengths versus Roller

The use of a spray gun has a number of advantages, which will necessarily affect the speed of the paint job and its quality.

Advantages of the spray gun:

- Using the tool eliminates the possibility of saving villi, bristles and other extraneous debris on layers of fresh paint applied;

- With the use of a spray gun, any work will be reduced several times in durationthan without him;

- Achieve significant consumables: the paint lays down in an even thin layer, there are no smudges, excess does not spill onto the floor;

- Airbrush - a reliable tool, does not require careful care, lightweight and small in size.

Why use a spray gun, tool classification

Most often, a spray gun or spray gun is used to paint furniture, wooden fences (seeHow and how to paint a wooden fence), metal coatings (including the car body), designer plaster and designer finishes.

There are many varieties of this equipment:

| Manual spray gun | This option is ideal for those who do not have significant experience in painting. When using a manual spray gun, uneven layer deposition, color unevenness are possible, but this type of tool is extremely reliable and easy to operate. Even a child can easily master it. |

| Pneumatic spray gun | The principle of its operation is based on the effect of compressed air, with which paint is applied to the surface. In most cases, such a tool is used in work on large areas: in factory shops and large shopping centers. However, a pneumatic spray gun is applicable for compact objects. |

| Vacuum installation | This principle is based on the contrast between the pressure inside the spray gun and the outlet to the environment. The resistance of the air slows down the flow of the coloring matter, which acts back to the pneumatic tool, when used, the air, on the contrary, pumps pressure. The main strengths of the airless system:

This method is actively used when painting the rolling stock of railways, subway cars and public transport. Using an airless system, metal surfaces are coated against rust. However, its use makes the paint layer too thin, subject to mechanical damage. |

| Electric spray guns | In this case, the paint is scattered across the surface of the electric pump. This method is especially common in domestic conditions when repairing residential premises. |

| The simultaneous use of vacuum and pneumatic systems | The combination of these two principles is common in the manufacture of aircraft and furniture factories. Surprisingly, in terms of effectiveness, all this professional equipment can be noticeably inferior to items made at home. Of course, this is achievable with certain skills and following all the rules when creating a homemade tool. |

Making a spray gun yourself

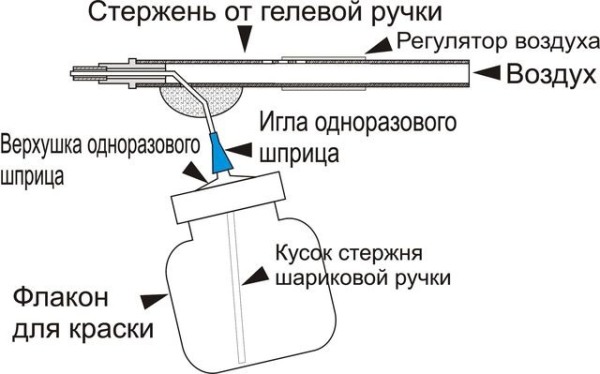

Atomizer - Ballpoint Pen

The most primitive option when creating a spray gun can be the use of a conventional ballpoint pen as the basis. Of course, such a tool does not replace factory equipment when painting large areas, but it may well be applicable at home or in the garage.

Attention: The main advantage is the time and ease of manufacture. In about 15–25 minutes, the spray gun from the handle will be ready.

It is also used easily. A man blows into the body of a pen, and paint comes out through its shaft.

You can adjust the intensity of the spray, but first it’s better to practice at some unnecessary area. Since this model does not exclude the possibility of paint getting into the mouth, it is better not to use a spray gun from a ballpoint pen for whitewashing.

What is this sprayer composed of?

To create a tool, you will need the following components:

- Dense foam, traditionally used to protect against frost and noise plasterboard floors. Instead, you can use rubber or a plastic part;

- Regular pen;

- Vessel with an expanded neck.

First you need to make a workpiece so that its lower part is tightly clogged in a vessel for paint. The quality of the resulting tool will largely depend on the breadth of its neck.

- Two holes should be drilled at the top. If you pierce the material with an awl, the holes will turn out uneven, which will be inconvenient when using a spray gun. Therefore, it is better to use a screwdriver. The first hole should be strictly vertical. For an emphasis it is possible to apply a cover from a vessel. Then you should drill a horizontal hole intersecting with the previous one.

- The next step will be immersion in the vertical channel of the edge of the rod from the handle. The second is its body. After that, paint is poured, and a cap is screwed into the neck of the bottle.

- If whitewashing is necessary, in addition to the use of water dispersion paint, the resulting tool can be upgraded.

- The use of a home-made spray gun, created on the basis of a ballpoint pen, will require a certain skill. However, first of all, you should study the technology of paintwork. Achieving a good result requires some skill. But at least before starting work, practice on some sheet you do not need.

Vacuum spray can as a tool base

There is another way to make a spray gun for paint, which will require an unnecessary spray can. In terms of performance, such a spray gun will only slightly differ from the analogue of a ballpoint pen, but its manufacture is much more complicated and most importantly very dangerous. Therefore, we will not paint it in detail, but only confine ourselves to mention.

Sprayer with vacuum cleaner hose

As a result of creating such a model, you will have a more serious tool, applicable equally for painting work (for example, a car) and for applying whitewash.

Attention: The basis is a conventional vacuum cleaner that acts as a compressor, that is, with the blowing mode turned on. The best are the models that pump high pressure.

In addition, there are vacuum cleaners that were originally equipped with nozzles for spraying liquids, such as, for example, the antediluvian “Whirlwind” and “Rocket”, manufactured in the USSR and not sold today. To adapt them to the use of water-based paint to cover the car body or whitewash, the vacuum cleaner is connected to the spray gun, while the vacuum cleaner itself acts as a compressor.

So how to make such a spray gun?

To create a model we need:

- An ordinary bottle is either made of glass or plastic, but always with a screw cap with a minimum diameter of 20-25 mm.

- Next, take a 20-cm copper or aluminum tube with a diameter of 4 mm. It must be bent and attached to the bottom of the nozzle on the hose of the vacuum cleaner. You can also take a powerful aerosol can instead of a compressor. Such are used in hairdressing salons. A brass nozzle is installed at the upper end of the tube. The end itself must be sanded before tapering. The top edge of the tube is inserted into the plug connector.

- The next step will be to equip our design with a holder so that it can be conveniently picked up. The handle is bolted into the shaft in which the groove is preliminarily made.

- After that, make a steel bracket with a hole matching the width of the socket. Assembly of the workpieces is carried out taking into account that the end of the suction tube is at the same level from the nozzle. Before starting work, be sure to test the resulting spray gun based on a hose from a vacuum cleaner on some unnecessary surface. Reduce or increase the pressure by adjusting the constriction of the tube.

- After you set the required pressure, fix the suction tube with a mounting foam in the groove that sticks to the lid of the vessel with paint.

Paint divider with compressor from the refrigerator

This unit will serve you for a long time, perform various tasks, but its manufacture at home will require considerable time and will take a lot of effort. Although all this will not be in vain, and you will get a very good tool. To produce a spray gun from a cooling unit, certain elements and consumables will be required.

Now we list its main components:

- Extensive container for coloring matter;

- Three hoses: the first is 40 cm long and the other two are 10 cm long .;

- 20 mm clamp (they may require several pieces);

- Filter from the car;

- Steel wire;

- Board and screws.

Before starting the main work, you need to do one more thing. Find something that can be used as a receiver. Such a thing can serve as a fire extinguisher, an unnecessary canister or in general any tightly closed metal container.

- To create the structure, fix the compressor from the refrigerator on a wooden base;

- After that, you need to determine where the air comes from. To do this, connect the part to the network and then determine which of the three tubes is pressurized. So this pipe is the way out. The other, respectively, is the inlet, and the third on refrigeration compressors is always sealed;

- Hoses of the corresponding diameters will then need to be connected to both tubes, and the joints are tightened with clamps;

- An important function of a sealed tube is to lubricate the compressor, so if the engine is running smoothly, it should not be touched;

- Drill two holes in the receiver body to which the hoses are connected. The one that is larger is attached to the compressor inlet pipe. The second, which is smaller, is attached to the exit;

- To be able to control the discharge pressure, it is necessary to install a manometer;

- The receiver is connected to the main superstructure of the supercharger. After that, with one hose, both parts are connected to each other, and the second pipe is attached to the filter, which stops small particles of dirt and debris in the air stream;

- Then it remains only to connect the spray gun.

In conclusion, to make the resulting unit more mobile, you can screw the wheels to its base.

Tips that make using a spray gun much easier and more efficient

So:

- When using a spray, direct it in circular motions for uniform layering of the coloring matter on the surface;

- The paint should lie on the surface strictly at an angle of 90o to the surface or you allow it to overspending;

- Spray paint without stopping in one place. Otherwise, its layers will turn out too thick;

- Before applying the next coat, wait until the previous solidifies completely;

- Do not be lazy to prepare the painted surface before starting work. It is very important!

So, there are several ways to make a spray gun with your own hands. How to adjust the spray gun will depend on the volume of fluid supply. Despite the complexity of the process, this will allow you to seriously save money and provide a quality tool for a long time and the price will not be high. The instructions will help you make the right choice.