Choosing an electric spray gun: what to look for

It is no secret that the highest performance is for air-operated spray guns. Here you can adjust the power, and besides, it always remains in stock.

The disadvantage of this equipment is the high price, because you need to buy not only the spray gun itself, but also the compressor for it. That is why, tools with electric drives are becoming increasingly popular among buyers, and in this article we will figure out which electric spray gun to choose and what you need to pay attention to when choosing.

The content of the article

What you need to know about electric spray guns

Having come to any hardware store, it is no wonder to be confused at the sight of a huge number of electric spray guns. Models vary in color, shape, performance and power.

So how do you choose it right? There are several recommendations for choosing, but before that you need to decide what colors you are going to work with. Different models are designed for different viscosities and maximum loads. If you load the tool, it just burns.

The thinnest paints are water based paints and nitro. They do not need high power for spraying and the weakest spray gun is suitable for working with them. It is a completely different matter if you work or plan to work with oil or silicone paints. They have a high viscosity, and they can not be diluted very much, as they lose their quality.

Here you will already need a more powerful tool with an engine of at least one kilowatt. There are quite thick ones, for example hammer paints or blacksmith enamels. It is very difficult to work with them, and not all spray guns are capable of spraying them.

What to look for

And this is far from the only criterion to which you should pay attention:

- Tank placement. It happens to be top and bottom. The upper placement is considered more optimal, since you can significantly change the angle of inclination, and in such spray guns the paint is injected into the tool under its own weight, which significantly reduces the load on the engine.

- Tool weight. Remember, for a long time you will have to hold the spray gun almost on an outstretched arm. Check how long you can hold the weight of the tool.

- Material of which the tank is made. There are two options: metal and plastic. Note that washing a metal tank is much easier, unlike plastic, which can also dry out after prolonged use and under the influence of solvents.

- Paid gum and tank adjoining. Inside the paint tank, as well as inside the entire tool, there should be compression. If it is not there, and the tool traps air from the outside, this will create additional load on the engine, and the atomization will be very small.

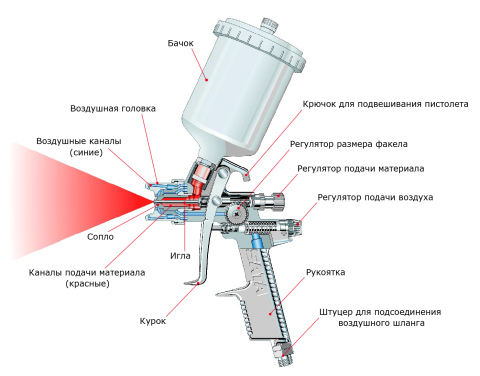

- Ability to adjust the spray torch. For painting different surfaces, different torch widths are required. So for flat surfaces it should be wide, but for curly products, on the contrary, narrow. Some electric spray guns do not provide for adjusting the supply of paint, and working with them is very inconvenient.

- The presence in the kit of additional parts. All spray guns sooner or later fail, but not through the fault of the user, but because consumables produce their life. It is necessary that the engine brushes, rubber bands and additional nozzles are included with the tool.

Of course, all these problems can be solved by simply buying the most expensive brand. Such manufacturers take into account all the nuances in their tool, from performance to ergonomics, but it will also cost a lot.

It does not always make sense to take a brand, especially if you are not going to work with it regularly. Such a tool is more suitable for professionals, and we will talk about spray guns in the middle price category.

Well, before we go any further, let's stop a bit and watch a video in this article that shows how an electric household airbrush works.

Important! Buying a branded tool is not a guarantee of high quality. It is this tool that is most often faked, and it is very difficult to identify counterfeit products, and even the presence of accompanying documentation will not give one hundred percent confidence that you have a product of this particular manufacturer, which is indicated in the name.

How to care

The instruction manual for the spray gun always comes with the tool, but this is not enough (seeHow to use a spray gun: tips from professionals) Care must be taken to ensure that the instrument lasts for many years.

Even a branded tool will fail after some time if there is no proper care for it, so here are a few rules that can not be ignored in any case:

- Before starting work, always purge the tool with the solvent you diluted with the paint. This is necessary in order to remove the remnants of the old solvent, which can curl new paint, as it was incompatible with it. Just fill the 1/5 tank with solvent, and press the button so that all the liquid is sprayed through the nozzle.

- After work, also blow out the tool with solvent. First you need to pour the liquid into the tank and rinse it, then drain everything and fill in a new portion, which must be sprayed. Repeat the procedure several times until all internal parts are washed with paint.

- After purging with solvent, unscrew the nozzle and thoroughly wipe the needle and all visible parts with a soft cloth to remove any remaining paint and solvent. The fact is that after drying some solvents I leave a white coating that looks like scale in a teapot. Over time, it accumulates on the needle and interferes with the passage of paint.

- Do not assemble the spray gun until all parts are thoroughly dry. Let them lie for a while on a rag, and only then screw the parts back on. This will also protect the tool from the appearance of scale, and the next time you work, you don’t have to worry about the solvent remaining inside.

- Always monitor the status of the filters. During operation, the spray gun not only pushes the air out, but also sucks it in with the dust and the paint that did not get on the metal. Over time, the filters become clogged and small particles enter the instrument, significantly reducing its working life.

- Avoid contact of rubber pads with solvents whenever possible. From this they harden and lose their sealing qualities. If the sealing gum has nevertheless got into the chemical environment, immediately remove it and thoroughly wipe it with a rag, then let it dry.

Important! And the most important rule: when working with your own hands, always use personal protective equipment.When spraying, many particles of paint continue to fly in the air, and can settle on the mucous membrane, causing irritation and even an allergic reaction.

Remember, if you strictly abide by these rules, then even the most budgetary tool will serve you faithfully for more than a year. The question is not so important which electrospray gun is better, much more important how you follow and care for it.

Which brand to prefer

So, with the question of how to choose an electrospray gun, we figured it out, and it's time to talk about specific models. We will not consider eminent brands, and we will pay attention to the instrument in the price category up to 5 thousand rubles, and for convenience we will present this in a small table.

| Model | Characteristics | ||||

| Productivity (l \ m) | Tank location | Tank capacity (liter) | Working power (W) | Weight, kg) | |

| 0.4 | lower | 0.8 | 800 | 2.2 | |

| 0.3 | lower | 0.8 | 600 | 1.5 | |

| 0.25 | lower | 0.8 | 80 | 1.2 | |

| 0.28 | lower | 0.8 | 85 | 1.5 | |

| 1.1 | lower | 0.7 | 600 | 2.4 | |

| 0.5 | lower | 0.8 | 500 | 2 | |

And most importantly, remember, no matter what electric paint spray gun you would like to paint at home, always pay attention to ergonomics, that is, how the tool lies in your hand. You should not experience any discomfort while working, and your hand should not get tired quickly.

If you are not able to hold almost three kilograms of weight for half an hour, then it may make sense to pay attention to an instrument with a smaller tank capacity. It’s better that you often add paint to it, but during your work your hands will not tremble with fatigue.